Energy-saving and environment-friendly type mechanical steam compressor

A steam compressor, energy-saving and environment-friendly technology, applied in the field of compressors, can solve the problems of impeller blade damage, inability to grade steam compression, poor atomization effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

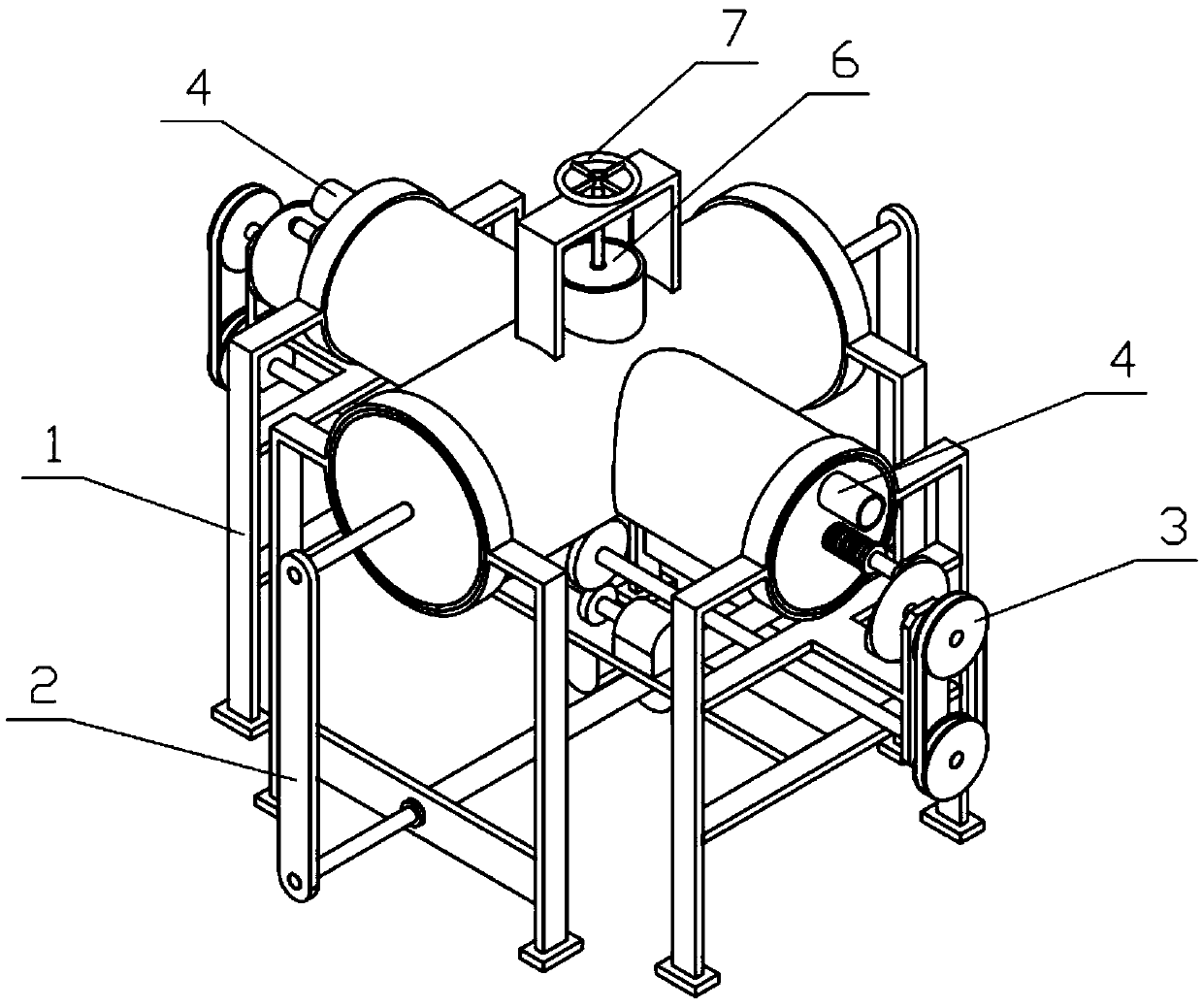

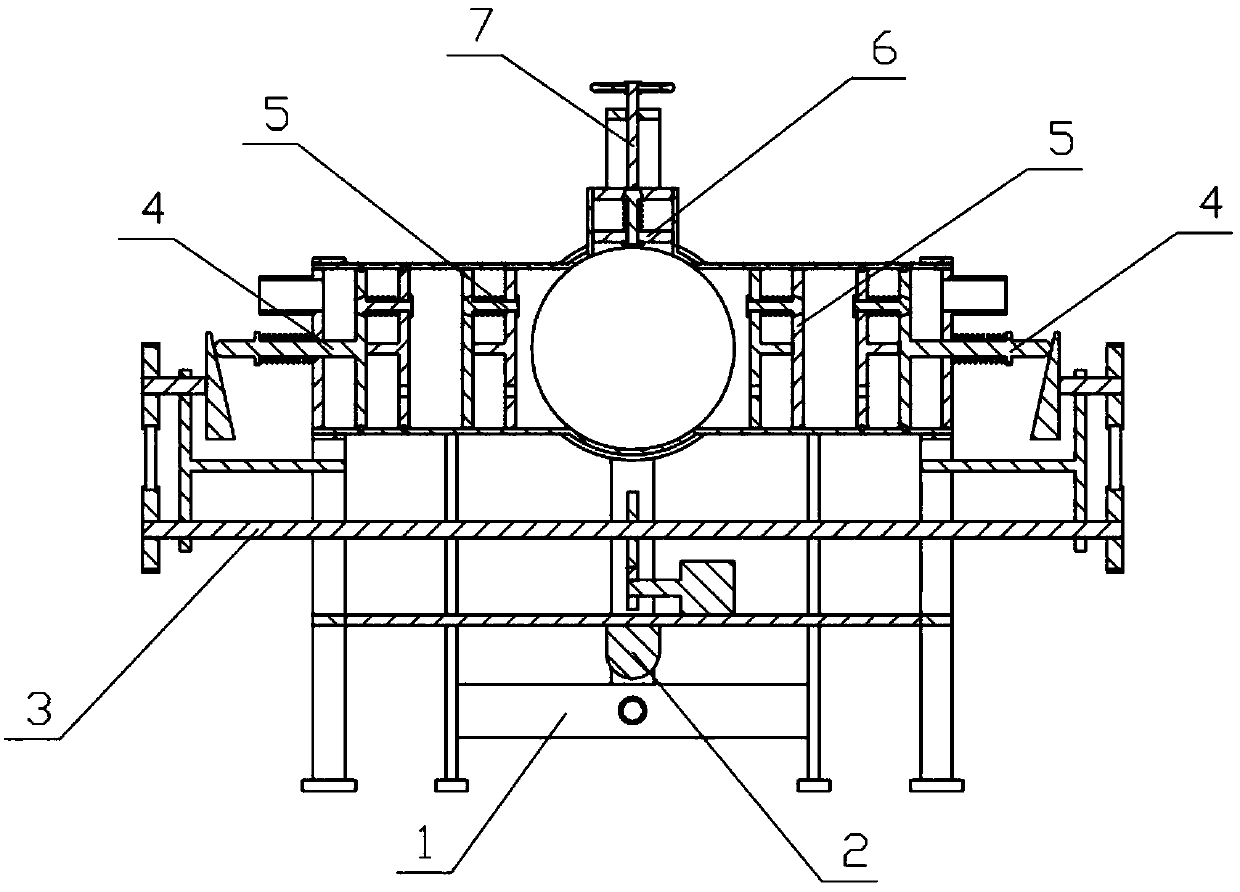

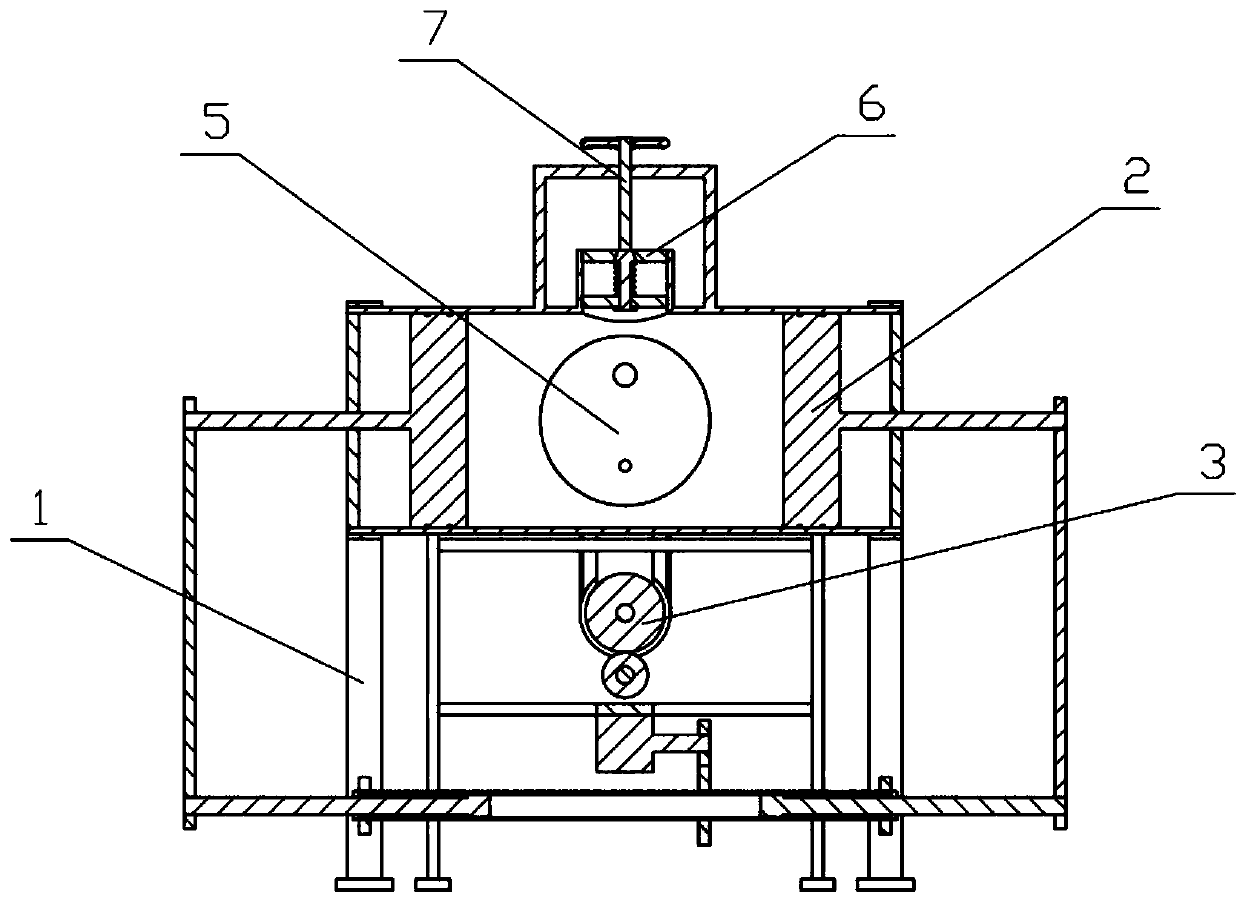

[0037] Combine below Figure 1-14 Describe this embodiment, an energy-saving and environment-friendly mechanical steam compressor, including a compression bracket 1, a compression mechanism 2, a power mechanism 3, an extrusion mechanism 4, a one-way mechanism 5 and a discharge mechanism 6, which can be compressed by two threaded rods The screw threads on 2-5 are in the opposite direction. When the two compression threaded rods 2-5 rotate, they drive the two compression plates 2-9 to approach or move away from each other. The steam inside is extruded, and the power mechanism 3 starts working in the working room. The two push wheels 3-8 set on the power mechanism 3 respectively push the two extrusion mechanisms 4 under the action of the compression spring II in the two compression cylinders II1- 2, and through the two one-way mechanisms 5 used against it, the water vapor is continuously injected into the compression cylinder I1-1, so that the water vapor in the compression cylin...

specific Embodiment approach 2

[0044] Combine below Figure 1-14 This embodiment will be described. This embodiment will further describe Embodiment 1. The compression bracket 1 further includes a discharge bracket 1-10, and the discharge bracket 1-10 is fixedly connected to the compression cylinder I1-1.

specific Embodiment approach 3

[0045] Combine below Figure 1-14 Describe this embodiment, this embodiment will further explain the second embodiment, the compression mechanism 2 also includes a sealing ring I2-10, two sealing rings I2-10 are fixedly connected to the two compression plates 2-9, four The outer sides of each sealing ring I2-10 are all interference fit in the compression cylinder I1-1; to ensure the sealing of the two compression plates 2-9 when sliding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com