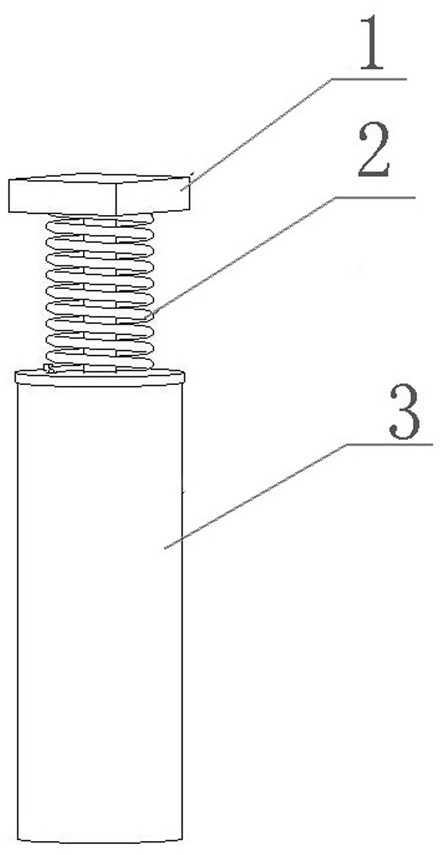

A barrel type shock absorber

A shock-absorbing device, a barrel-type technology, applied in the direction of shock absorbers, springs/shock absorbers, shock absorbers, etc., can solve problems such as reducing mechanical use efficiency, loosening, equipment damage, etc., and achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

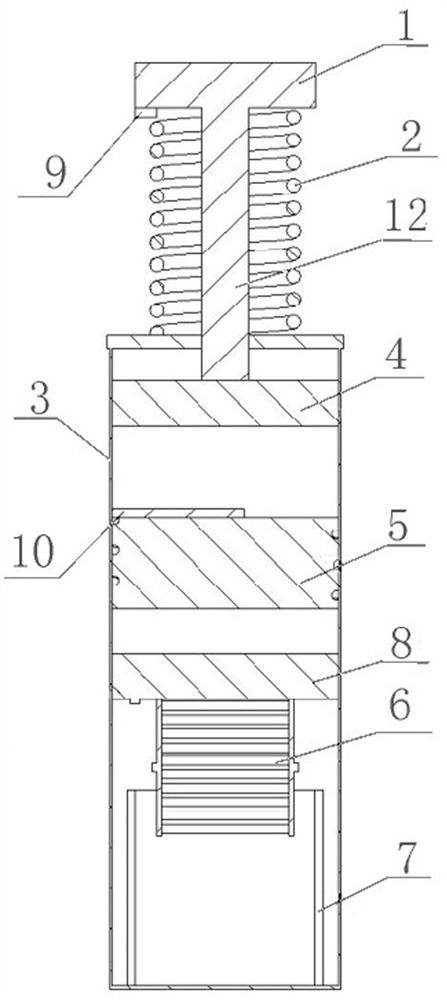

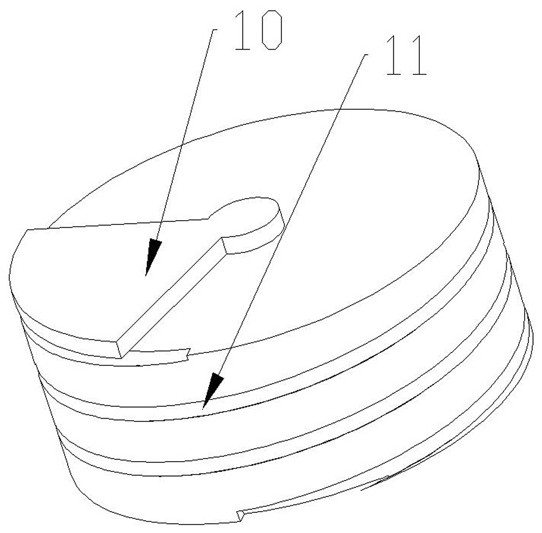

[0024] A cylindrical damping device, comprising a cylinder 3, a support plate 1, a SAW acceleration sensor 9, a shock absorbing spring 2, an upper piston 4, a middle partition 5, a lower piston 8, a conductor assembly 6 and a permanent magnet 7; The upper piston 4, the middle partition plate 5, the lower piston 8, the conductor assembly 6 and the permanent magnet 7 are all arranged in the cylinder 3; the upper piston 4 is supported by the piston rod 12 passing through the upper wall of the cylinder 3 The plate 1 is connected; the SAW acceleration sensor 9 is installed below the support plate 1; the shock absorbing spring 2 ring is arranged outside the piston rod 12 and is located between the support plate 1 and the upper wall of the cylinder 3; the middle partition 5 It is arranged below the upper piston 4, and the middle partition 5 is fixedly welded on the inner wall of the cylinder body 3; the middle partition 5 is provided with a spiral damping channel 11, and a stepping mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com