Absorbing/compressing mixed cycle system with liquid spraying loop and heat pump heating method

A circulating system and loop technology, which is applied in the field of absorption/compression mixed circulation system and heat pump heating, can solve the problems of difficulty in selecting a compressor and increase the exhaust temperature of the compressor, so as to improve the adaptability, reduce the suction temperature, improve the Application-wide effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

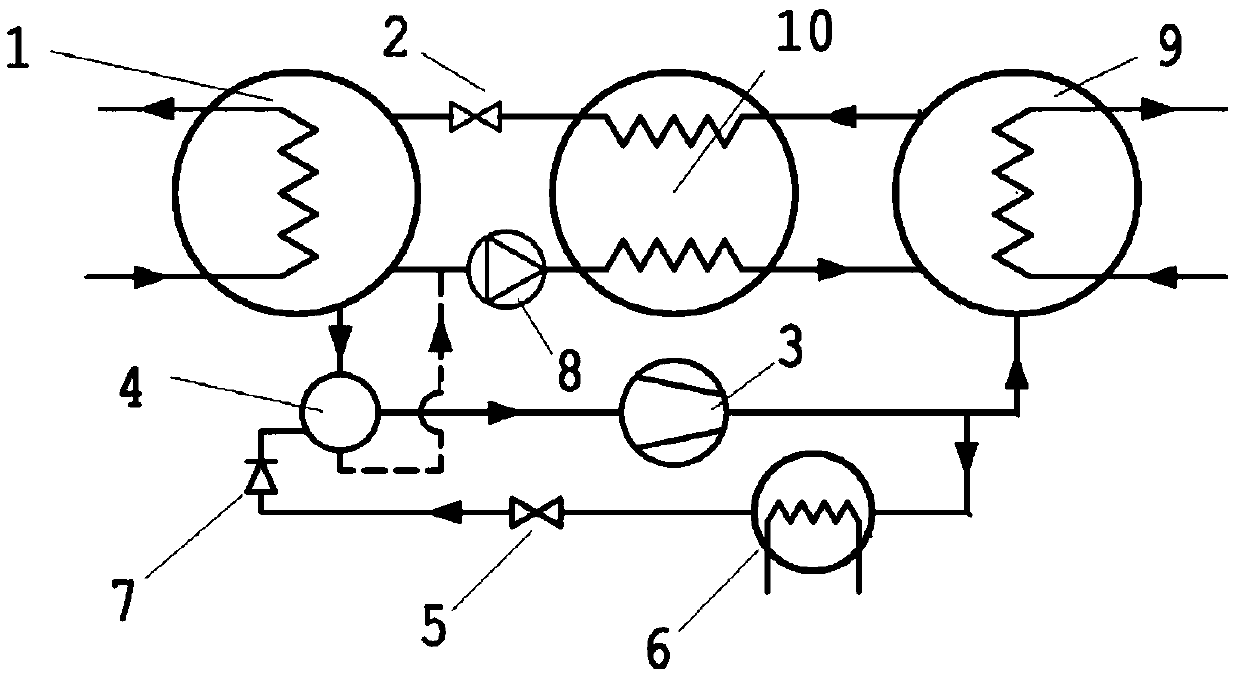

[0034] In this embodiment, the hybrid heat pump circulation system with liquid injection circuit specifically includes:

[0035] Example

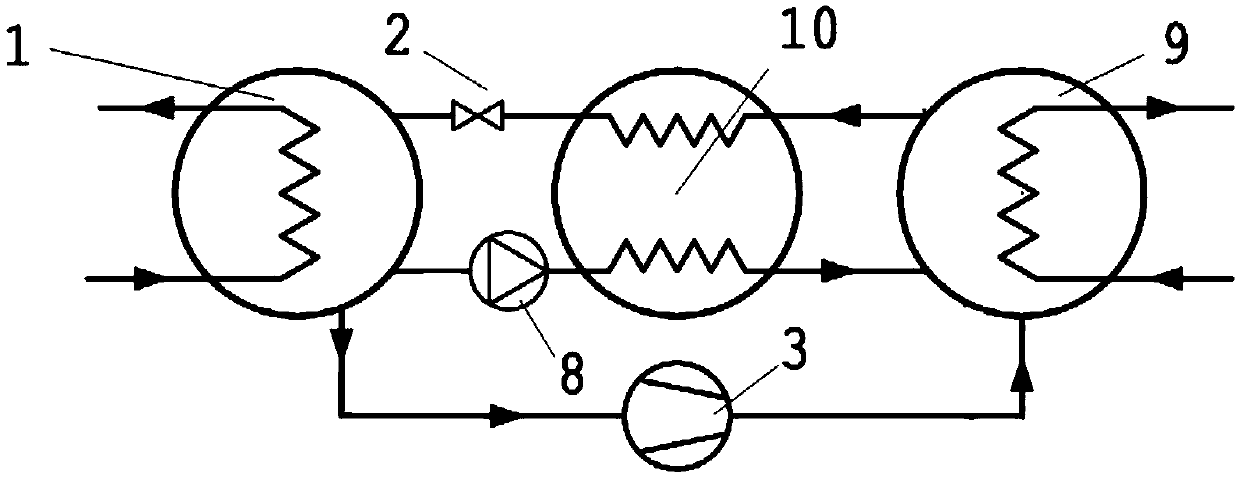

[0036] An absorption / compression hybrid cycle system with a liquid injection circuit, including a generator 1: including a first heat exchange channel of the generator and a second heat exchange channel of the generator, and the second heat exchange channel of the generator is used for evaporative refrigeration The refrigerant saturated solution generates refrigerant wet gas and refrigerant dilute solution; absorber 9: includes the first heat exchange channel of the absorber and the second heat exchange channel of the absorber; the low temperature flow path: passes through the first heat exchange channel of the generator, It is used to absorb heat from the low-temperature section and transfer the heat to the second heat exchange channel of the generator; the second solution flow path: a solution pump 8 is installed in it, and the refrigeran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com