Miniature moving-magnetic series-connection two-stage linear compressor

A linear compressor and compressor technology, applied in the field of compressors, can solve the problems of large compression ratio and high exhaust temperature of compressors, and achieve the effects of lower exhaust temperature, enhanced reliability, and easy oil-free lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

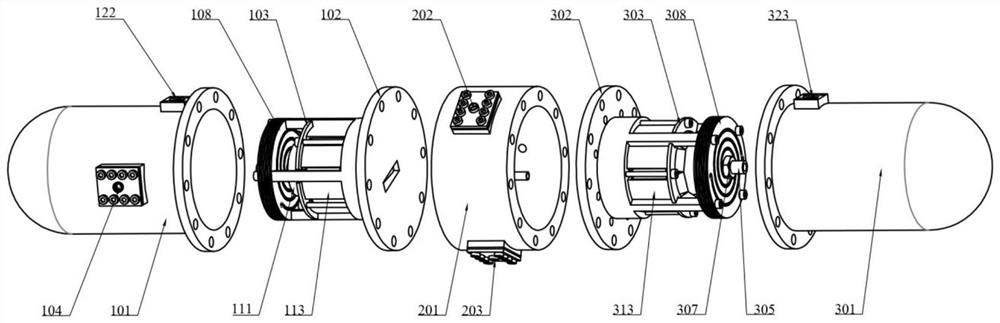

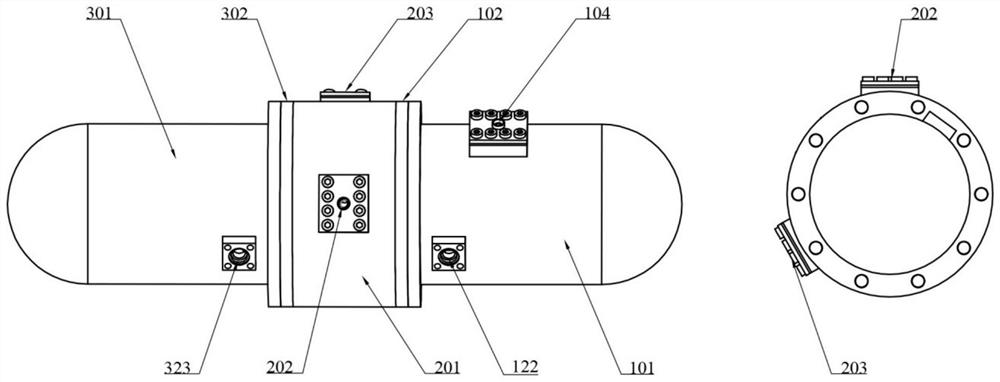

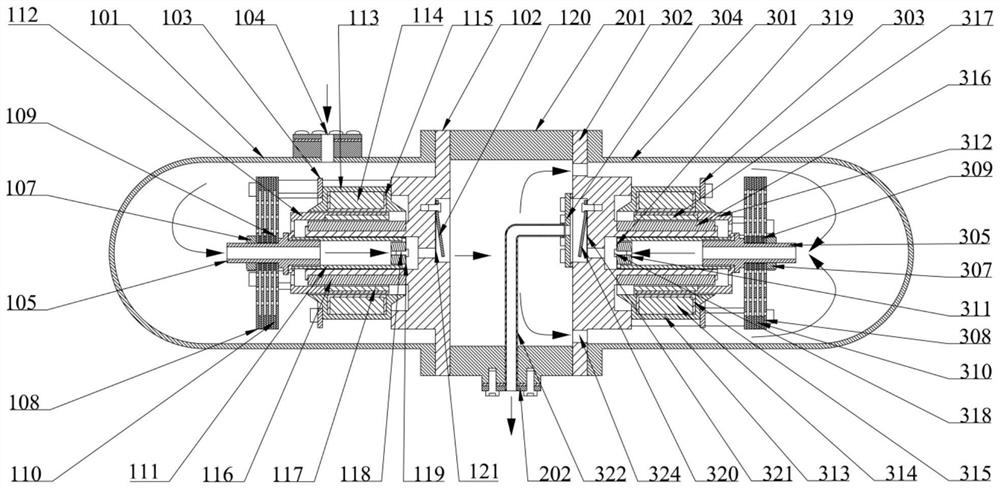

[0025] Such as figure 1 As shown, a miniature moving magnet series two-stage linear compressor includes a low-pressure stage compressor, an intermediate kit 201 and a high-pressure stage compressor. Both the high-pressure stage compressor and the low-pressure stage compressor include a shell, an integral frame, a dynamic subsections as well as linear motors.

[0026] A power interface 122 and a suction port 104 are arranged on the housing 101 of the low-pressure stage compressor.

[0027] The overall frame 102 of the low-pressure compressor has an exhaust hole, and a tongue-shaped reed exhaust valve 121 and a lift limiter 120 are installed. The exhaust valve 121 and the lift limiter 120 are fixed on the On the integral frame 102, the inner yoke 116 is glued on the integral frame.

[0028] The mover part of the low-pressure stage compressor includes a leaf spring 108, a small washer 109, a leaf spring washer 110, a connecting piece 105, a piston 111, a permanent magnet bracke...

Embodiment 2

[0044] Such as Figure 5 As shown, the structure of the high-pressure stage compressor and the low-pressure stage compressor in Embodiment 2 is the same as that of the compressor in Embodiment 1, and the operating principle is also the same, the difference is:

[0045] There is an air inlet 203 on the intermediate sleeve 201, through which the saturated refrigerant vapor from the intercooler enters the cavity of the intermediate sleeve 201, mixes with the refrigerant gas compressed and discharged by the low-pressure stage compressor, and is then compressed by the high-pressure stage. The circular air suction hole 324 on the overall frame of the machine enters the air suction cavity of the high-pressure stage compressor. When the pressure in the compression cavity of the high-pressure compressor is lower than the pressure in the suction cavity, the refrigerant gas enters the compression cavity through the suction channel in the high-pressure compressor connector 305 and the pis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com