Tolerance settlement monitoring device, system and method

A settlement monitoring and tolerance type technology, applied in the direction of hydrostatic pressure and the like, can solve the problems of increasing the error value of the hydrostatic level, greatly affecting the test accuracy, affecting the test accuracy, etc. The effect of increasing construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

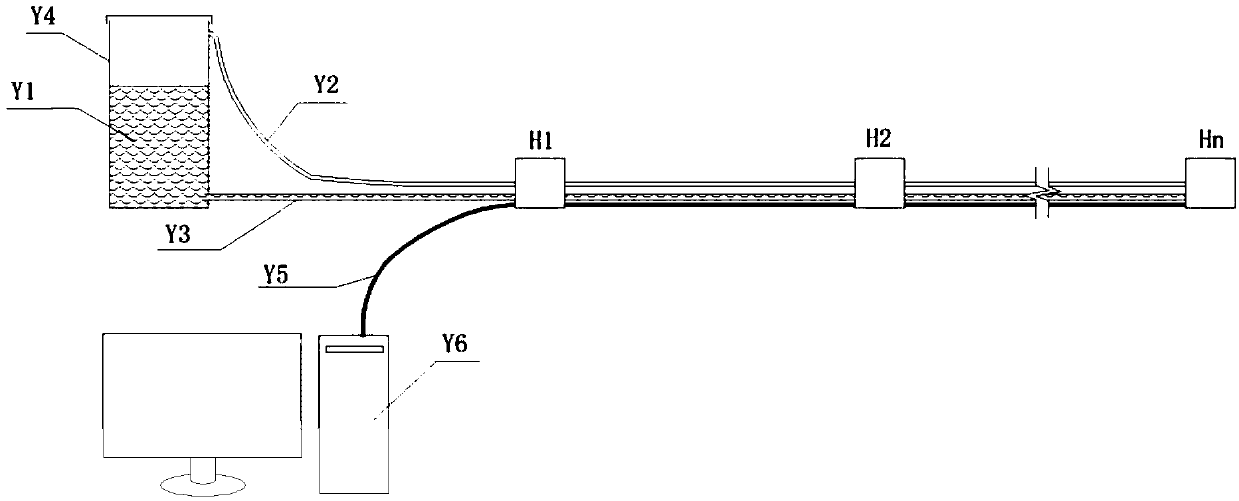

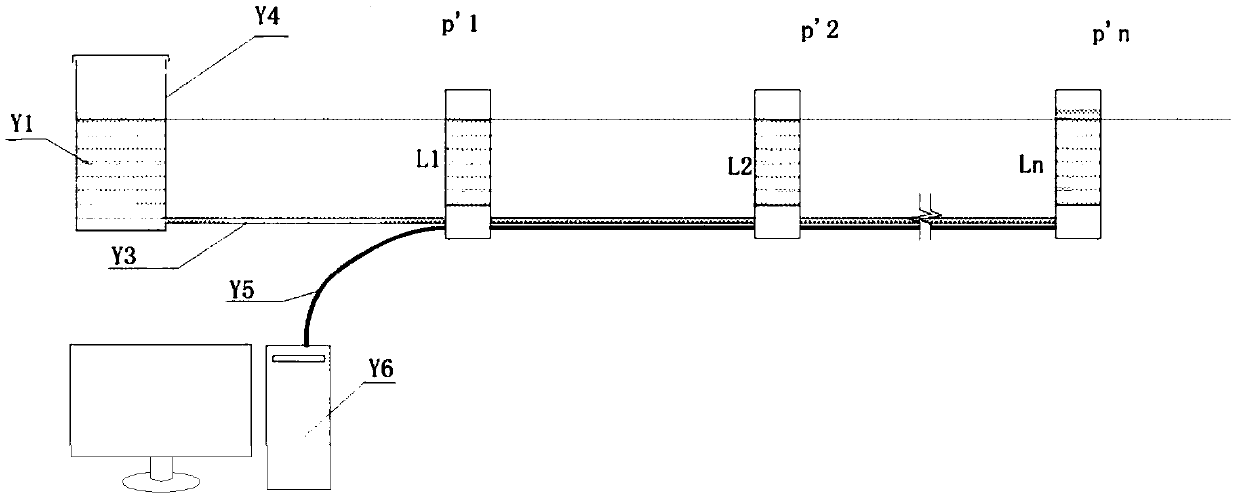

Image

Examples

Embodiment

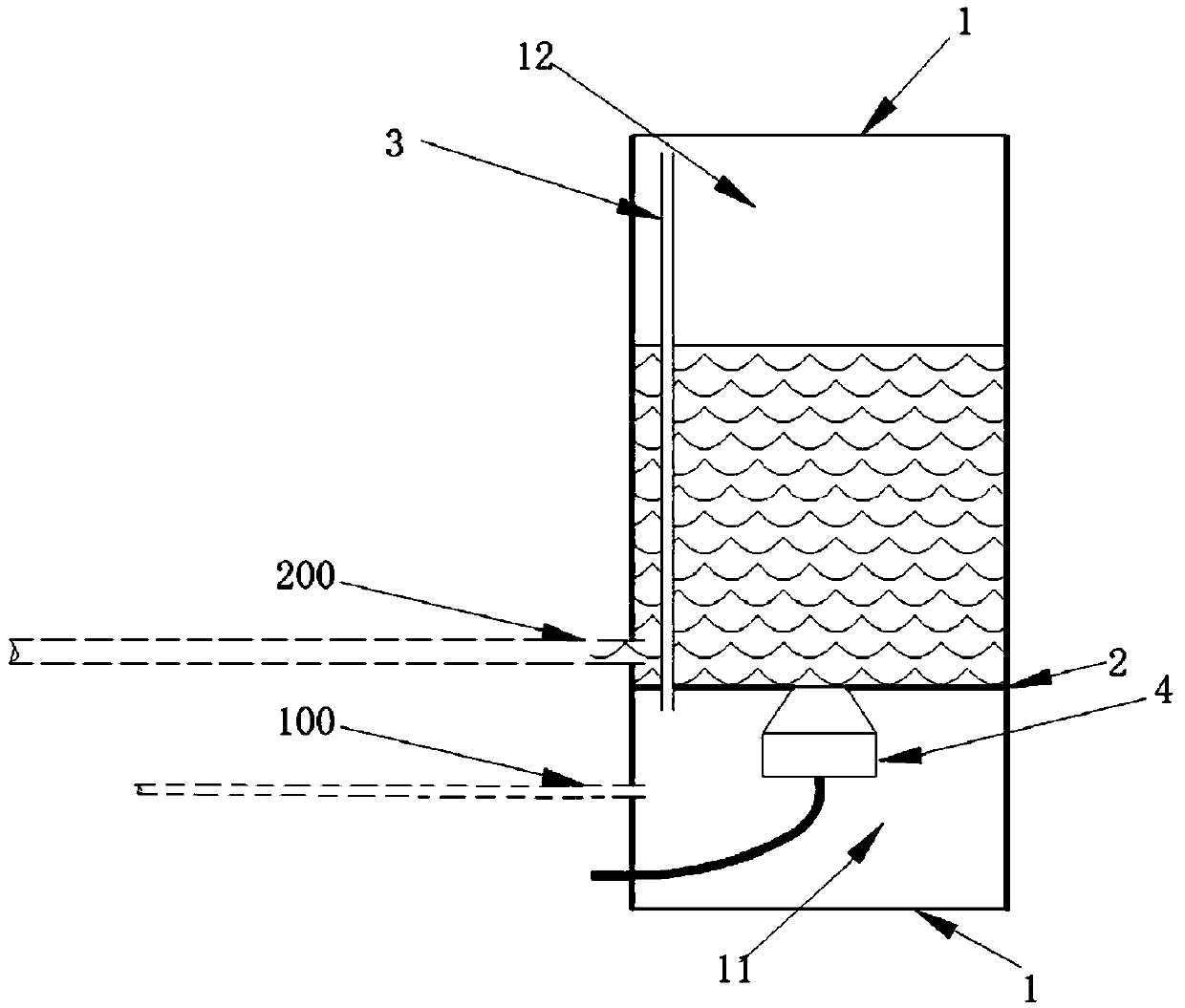

[0050] Such as image 3 As shown, a tolerance type settlement monitoring device is connected with an air guide tube 100 and a liquid guide tube 200, and the tolerance type settlement monitoring device includes a tank body 1, a partition plate 2, an air pipe 3 and a pressure sensor 4; The partition plate 2 is provided in the tank body 1, and divides the tank body 1 up and down into a sealed liquid storage chamber 11 and an air chamber 12; the sealed liquid storage chamber 11 stores a liquid medium; the pressure sensor 4 Installed in the air cavity 12, the partition plate 2 is provided with a hydraulic detection through hole, the detection probe of the pressure sensor 4 is installed in the hydraulic detection through hole; the vent pipe 3 is arranged in the tank body 1, The vent pipe 3 runs through the partition plate 2; one port of the vent pipe 3 is located in the sealed liquid storage chamber 11 and is higher than the level of the liquid medium, and the other port of the vent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com