Detecting device for detecting sealing property of bearing sealing elements

A detection device and a bearing sealing technology, which can be used in the direction of measuring the acceleration and deceleration rate of the fluid, using the liquid/vacuum degree for liquid tightness measurement, etc., which can solve the problems of abrasive wear, fatigue spalling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

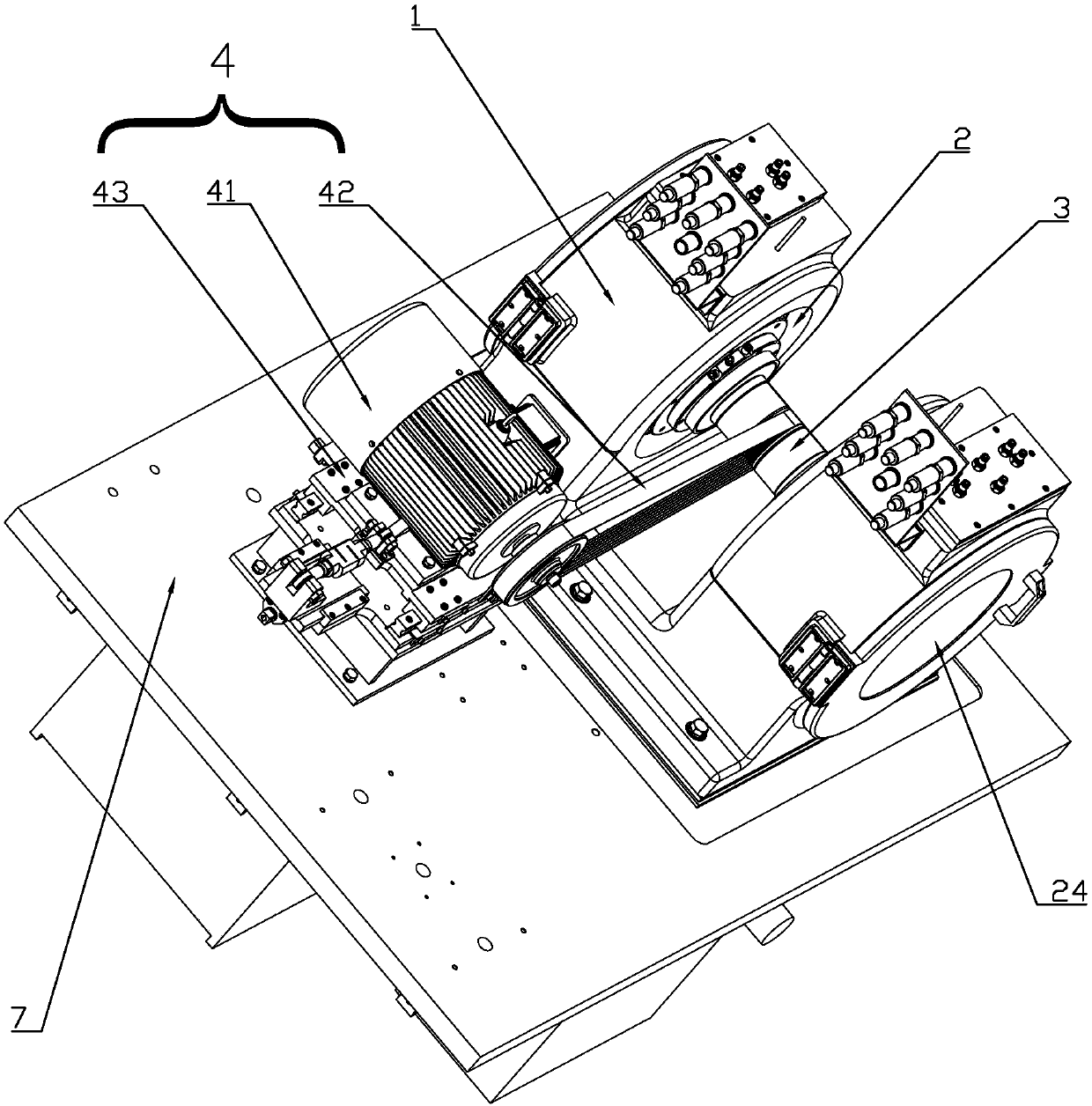

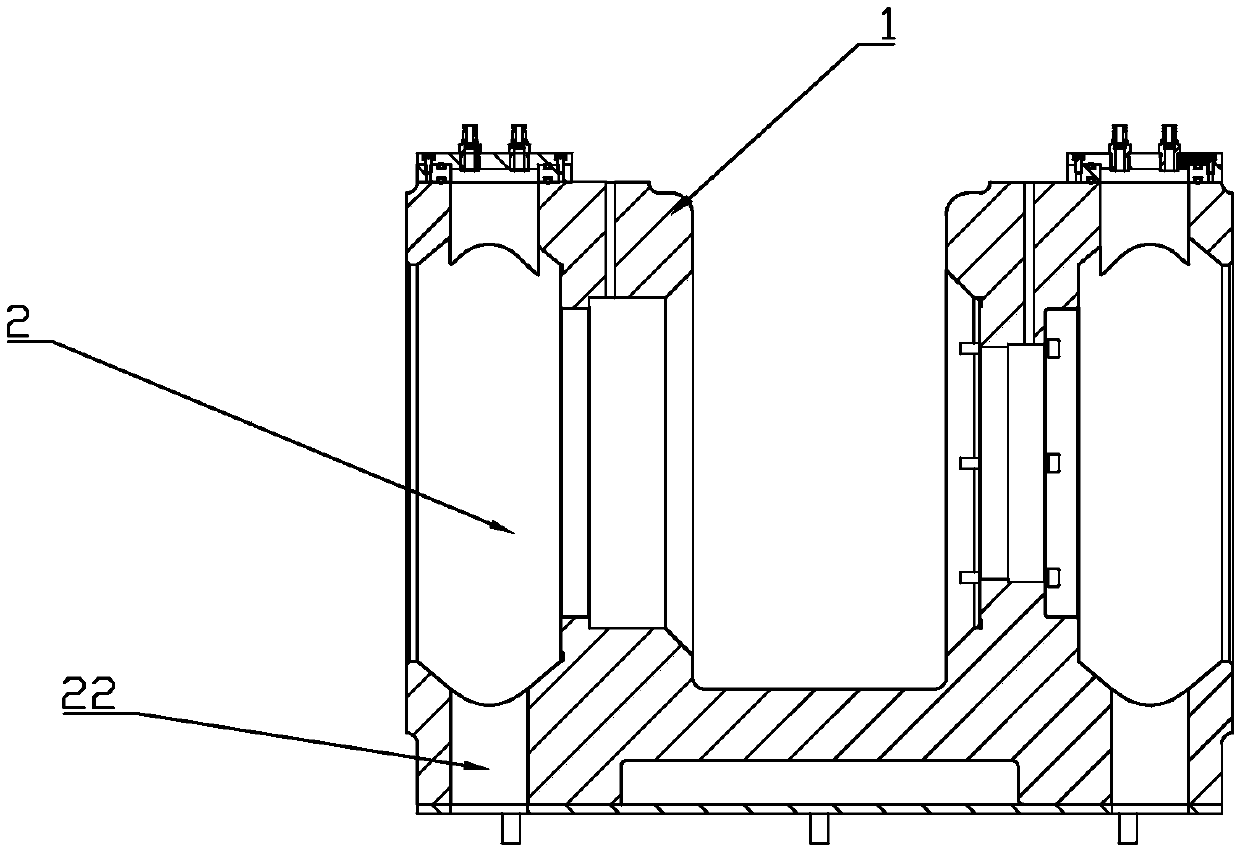

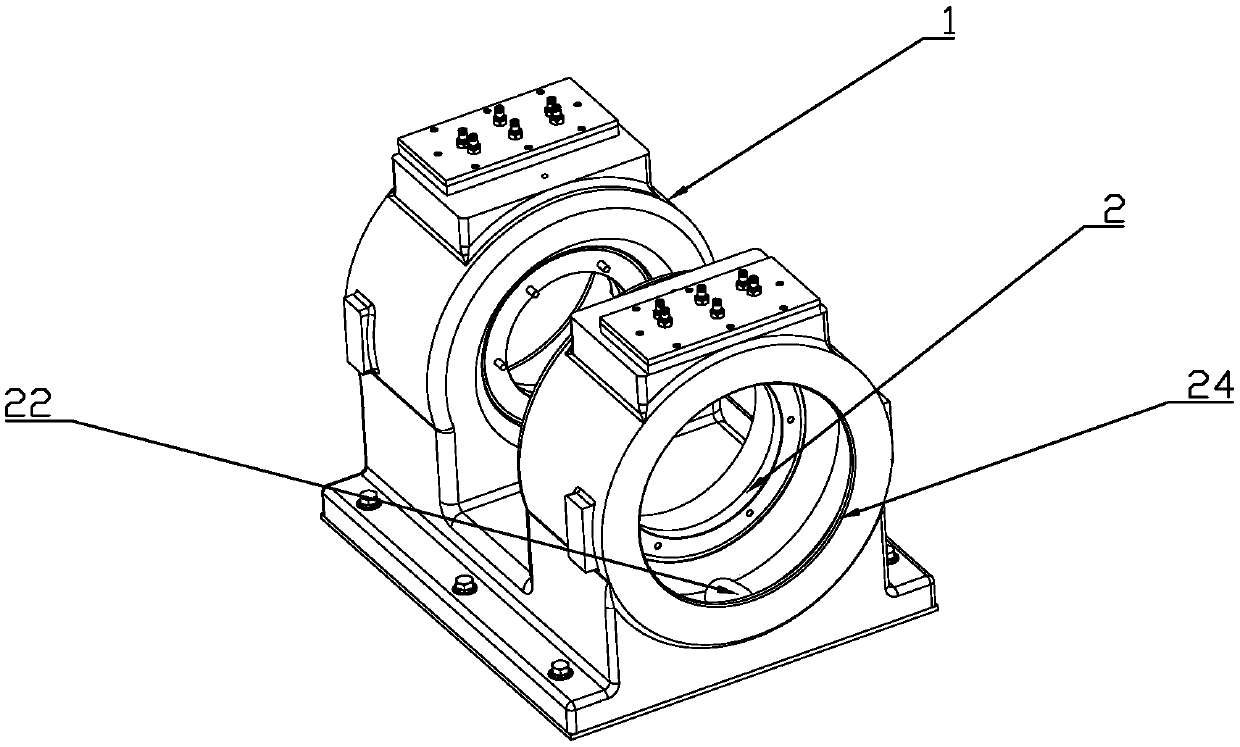

[0029] Depend on Figure 1 to Figure 7It is disclosed that the present invention provides a detection device for detecting the tightness of bearing seals, including a detection seat 1, a detection chamber 2 is arranged in the detection seat 1, a rotating main shaft 3 is pierced in the detection chamber 2, and the rotation The main shaft 3 is rotatably installed on the detection seat 1, and the rotating main shaft 3 is connected with a power mechanism 4 for driving its rotation. A fixed sleeve 21 is also fixed in the detection chamber 2, and the fixed sleeve 21 is sleeved on the rotating main shaft 3. , an installation cavity for installing a test assembly 5 is formed between the fixed sleeve 21 and the rotating main shaft 3, and the test assembly 5 includes a test bearing 51 and two test seals 52, and the two test seals 52 are separately arranged On both sides of the test bearing 51, an air pressure detector is arranged outside the detection seat 1, and the air pressure detect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com