A computer cpu cooling device

A heat dissipation device and computer technology, applied in the field of computers, can solve the problems of poor heat dissipation, space occupation, and difficult maintenance, etc., and achieve the effects of improved heat dissipation, easy maintenance, and increased contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

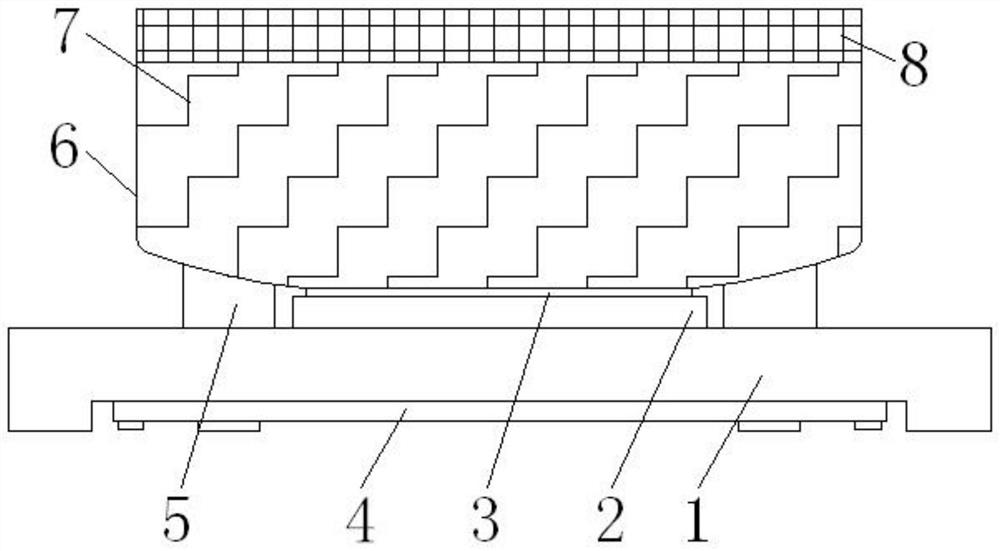

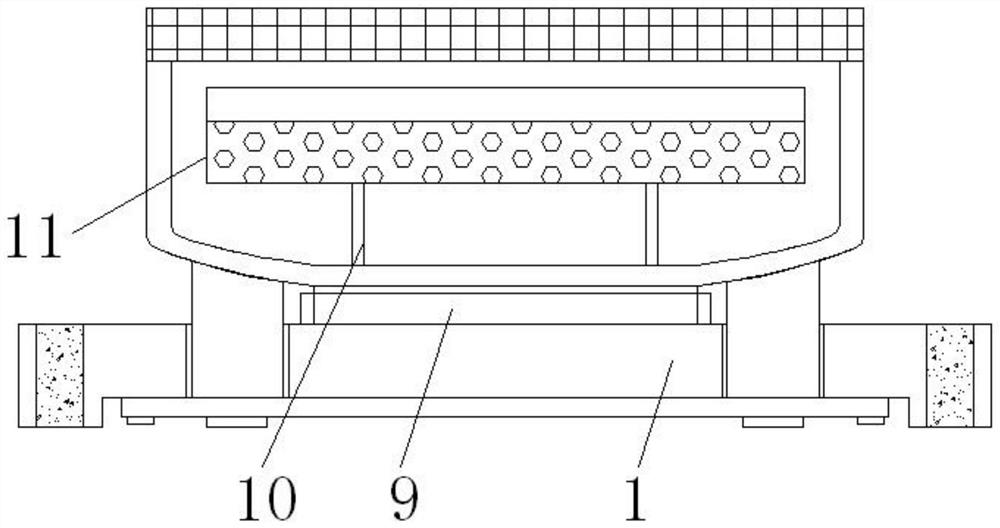

[0024] Embodiment one, with reference to figure 1 and 2 , a computer CPU cooling device, comprising a fixed base 1, the top center of the fixed base 1 is welded with a fixed frame 2, the fixed base 1 and the fixed frame 2 are made of good heat dissipation and heat-conducting materials, and the fixed frame 2 is embedded with a CPU9 , in order to fix the CPU9 through the fixed frame 2, the top of the fixed base 1 is located on both sides of the vertical center line, and two vertical bars 5 are arranged through it, and the bottom center of the fixed base 1 is provided with a fixed plate 4, and the fixed plate 4 is connected with the two by screws. Two vertical rods 5 are threaded, and the other ends of the two vertical rods 5 are welded with a heat dissipation cover 6. The heat dissipation cover 6 has a double-layer structure, so that the interior of the heat dissipation cover 6 is hollow, so as to realize heat dissipation for the circulation of objects. The top of the heat dissi...

Embodiment 2

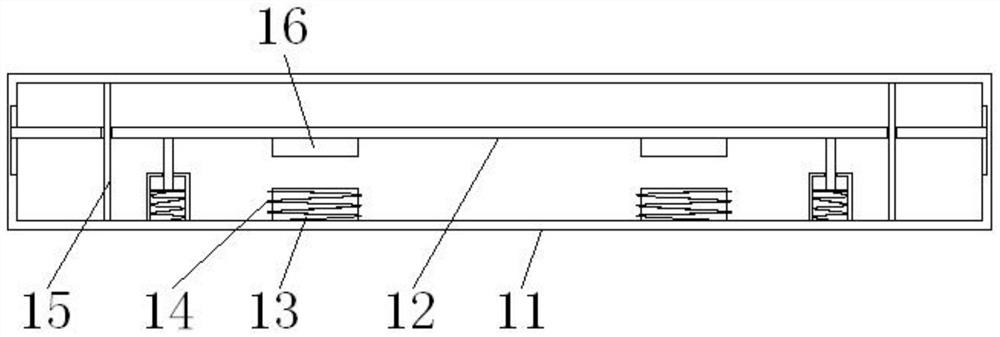

[0025] Embodiment two, refer to Figure 2-4 , the center of the bottom of the cooling cover 6 is welded with a semiconductor cooling chip 3, and the low temperature end of the semiconductor cooling chip 3 is welded with the cooling cover 6, and the high temperature end is bonded to the CPU9. A temperature difference is formed on the surface of the cover 6. Using this temperature difference phenomenon, an excellent heat dissipation effect is achieved. A compressor plate 12 is slidably embedded in the box body 11. The compressor plate 12 is vertically provided with two slide bars 15, and two Both ends of the slide bar 15 are welded with the inner wall of the box body 11, and the positioning of the compressor plate 12 is realized by the two slide bars 15. The bottom of the inner wall of the box body 11 is welded with two limit tubes 17, two limit tubes The top center of 17 is provided with a pressure rod 19 through, and the pressure rod 19 is positioned at two round blocks 18 in ...

Embodiment 3

[0026] Embodiment three, refer to figure 2 and 5 , the outer wall of the box body 11 is uniformly provided with through holes, through which the box body 11 can be ventilated with the outside world, the cooling net 8 is formed by the horizontal tube 81 and the vertical tube 82, and the horizontal tube 81 is connected with the vertical tube 82, and the horizontal tube 81 is connected to the vertical tube 82 Pipe 81 and standpipe 82 form a reticular structure, can increase the contact area with air by radiating net 8, be provided with the liquid of low temperature pollution-free in radiating cover 6, CPU9 can transfer heat on radiating cover 6, the liquid that is heated will The gas is formed to enhance the heat dissipation effect of the heat dissipation scales 7, and the hot gas will enter the heat dissipation net 8 and be cooled in the horizontal pipe 81 and the vertical pipe 82 to form a liquid, which will flow into the bottom along the inner wall of the heat dissipation cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com