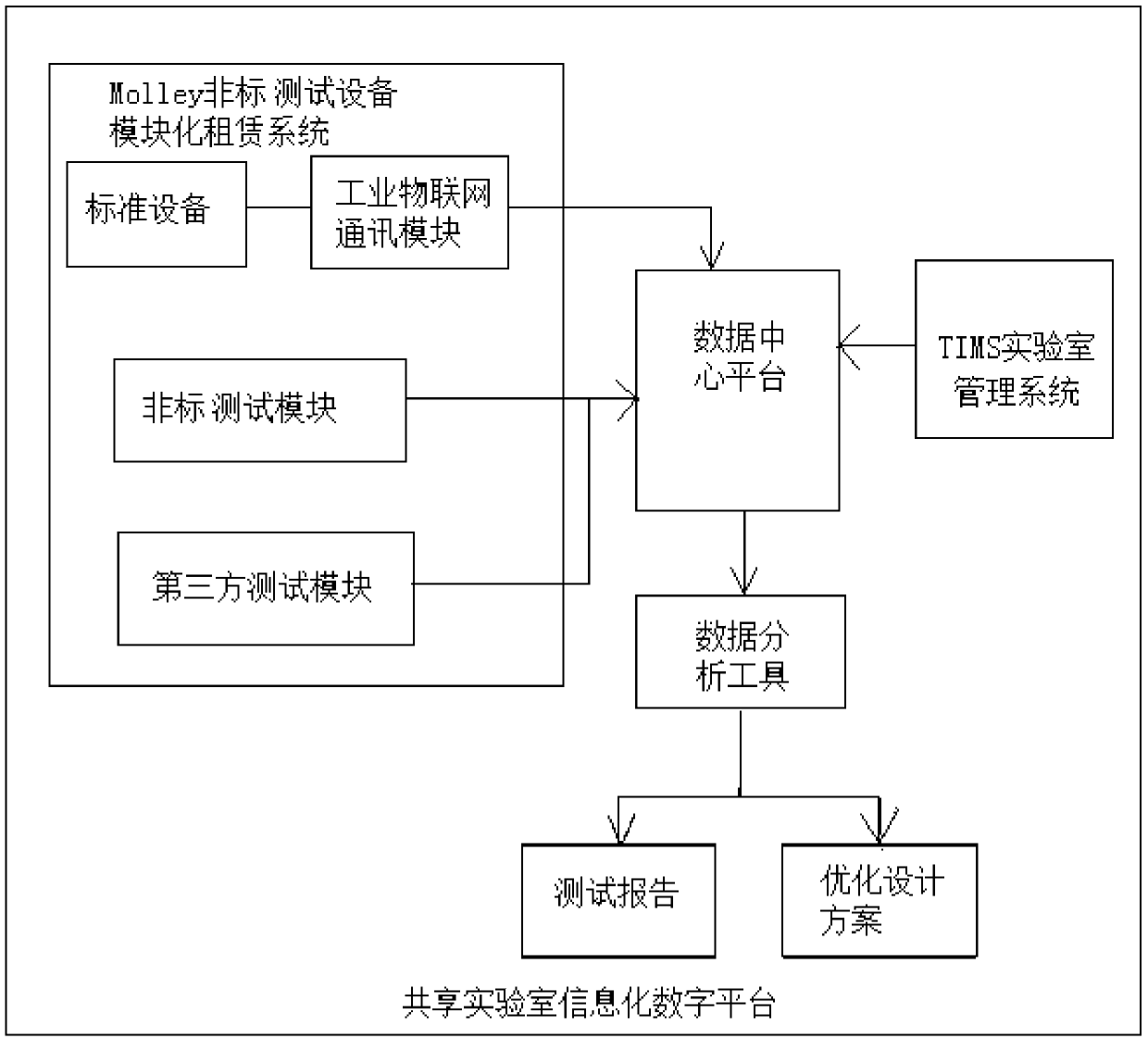

Shared laboratory informatization digital platform, leasing system and laboratory management system

A laboratory and platform technology, applied in the field of laboratory equipment sharing for functional testing, can solve the problems of high price and low utilization of laboratory equipment, and achieve the effect of improving utilization and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This example provides a shared laboratory informatization digital platform. Non-standard test modules, third-party test modules, standard equipment, experimental sites, industrial Internet of Things communication modules, etc. for various functional tests can be shared through this platform. Other customers Select relative non-standard test modules, third-party test modules, standard equipment, etc. on the platform according to the required test functions. The test equipment is rented to complete the functional test of the customer, and the customer does not need to purchase the relevant test equipment. The sharing of this example The laboratory informatization digital platform integrates the idle resources of various laboratories such as non-standard test modules, third-party test modules, standard equipment, and experimental sites, so that customers can make reservations for renting experimental sites, standard equipment, and test modules on the platform. etc., providi...

Embodiment 2

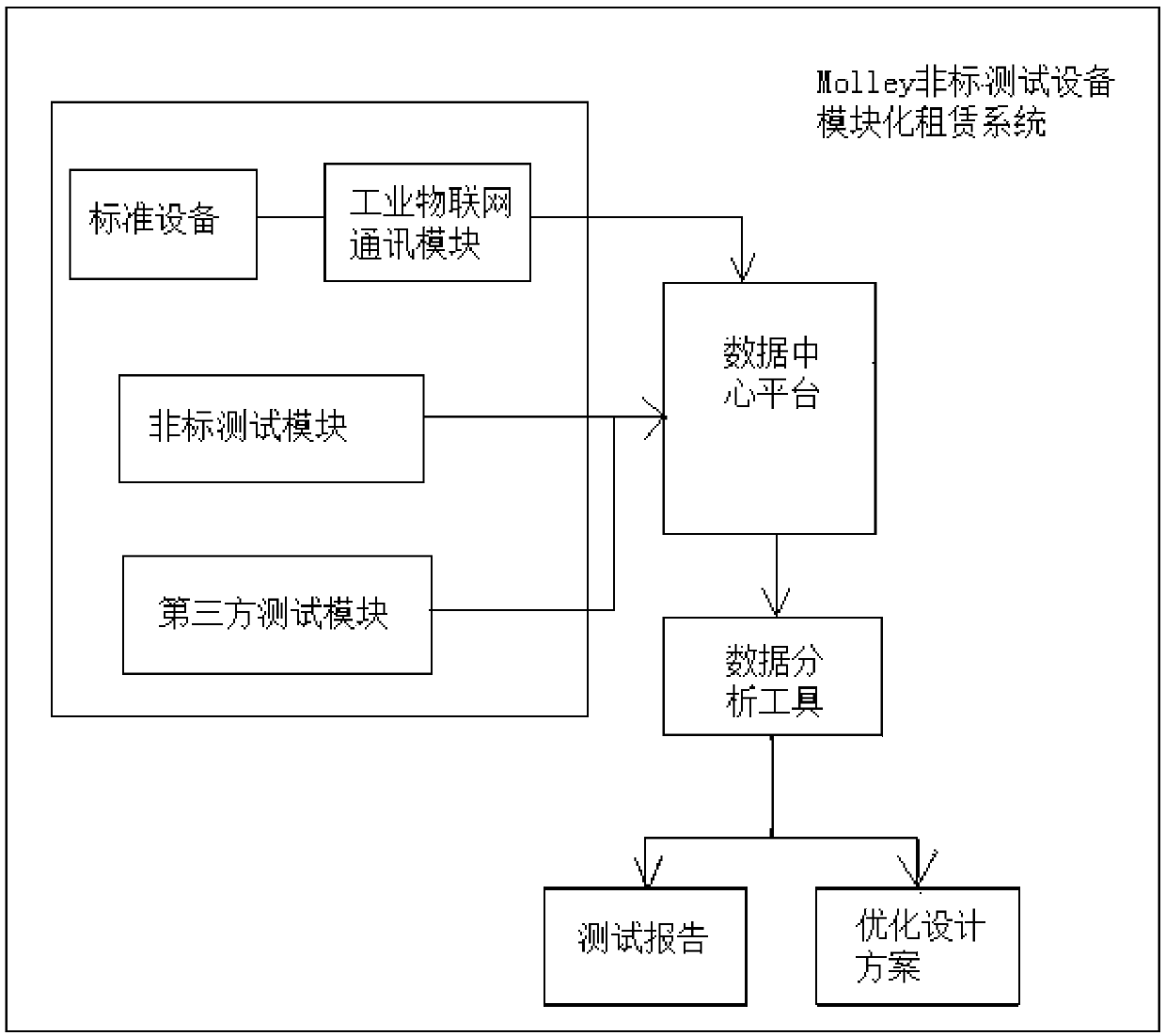

[0057] Based on Embodiment 1, this example provides a Molley non-standard test equipment modular rental system, the schematic diagram of which is as follows figure 2 shown, including:

[0058] Registration module for customers to register accounts;

[0059] Rental modules, at least provide customers with non-standard test modules, third-party test modules, industrial IoT communication modules and controllers required for various laboratory tests, so that customers can choose the corresponding test modules according to the required test functions, so that The test module selected by the customer and the controller supporting the test function constitute the test environment for the test function required by the customer, and an order list is generated after the customer selects the corresponding test module;

[0060] The data center platform is used to store and manage the test data of the test module;

[0061] Data analysis tools are used to retrieve test data stored in the...

Embodiment 3

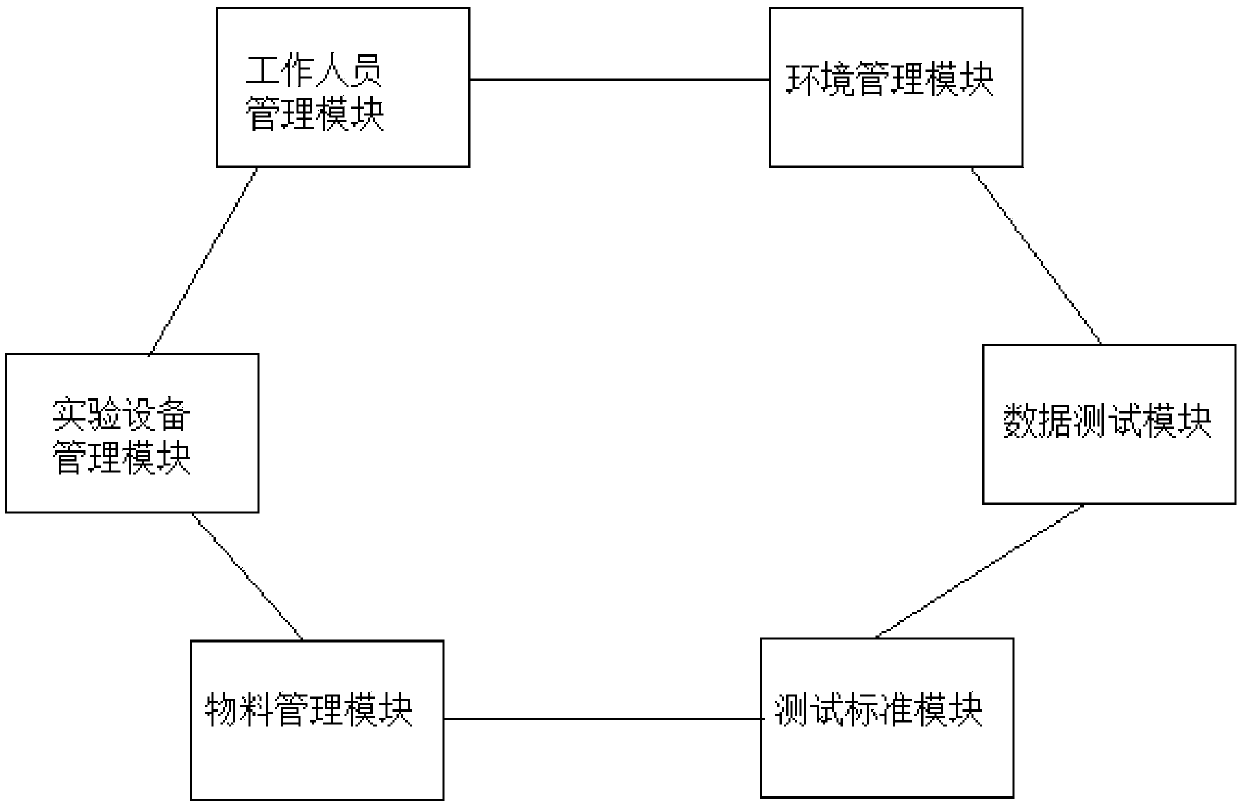

[0071] Based on the first embodiment, this example provides a TIMS laboratory management system, the schematic diagram is as follows image 3 As shown, it is used to logically correlate and optimize the staff, experimental equipment, materials, test standards, test data, and test environment in the laboratory, and realize the intelligent management of the laboratory through the TIMS laboratory management system, specifically including:

[0072] The staff management module provides each staff with a management page that matches the position, so that each staff can keep abreast of the current work content through their respective management pages;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com