Chemical decontamination room of fire fighting truck and fire fighting truck

A technology for chemical washing and fire trucks, which is applied in fire rescue and other fields, can solve the problems of no corrosion resistance, low decontamination efficiency, and inability to perform decontamination operations, etc., and achieve weight reduction, simple processing and assembly processes, and decontamination process The effect of saving trouble and effort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be further described in conjunction with the following examples and accompanying drawings.

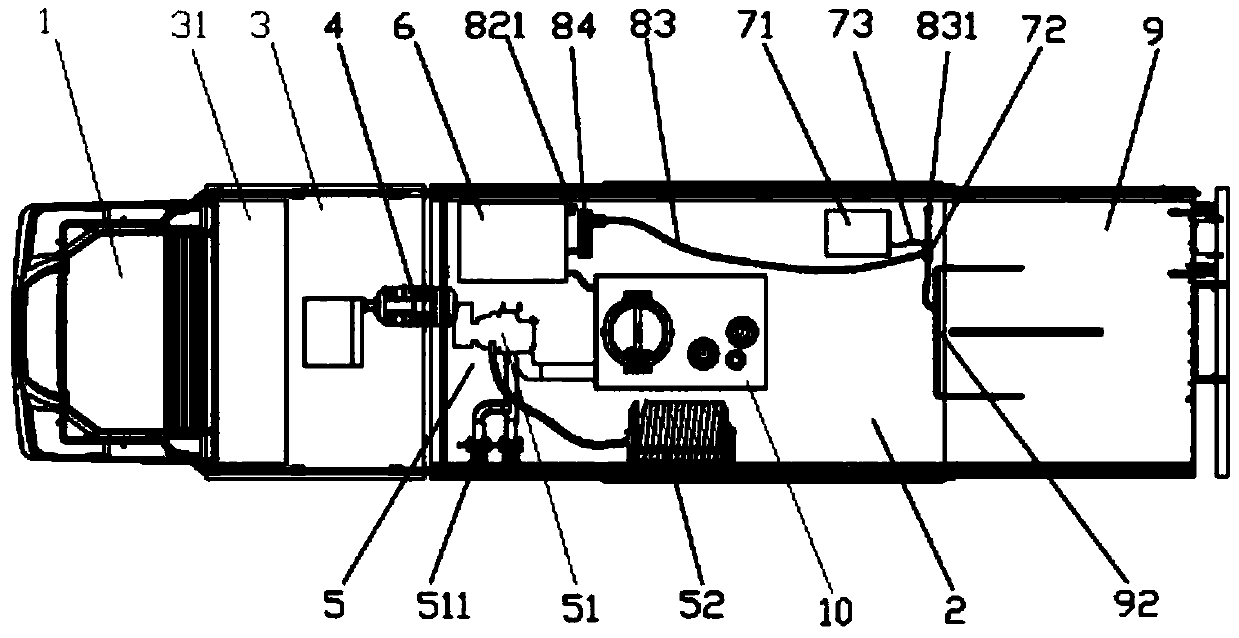

[0060] a fire truck, such as Figure 1 to Figure 5 As shown, it includes a driver's cab 1 and a compartment 2. A power supply unit, a decontamination device and a chemical decontamination chamber 9 are arranged in the compartment 2. The decontamination device includes a water storage tank 10, a decontamination heating machine 6, and is used to provide chemical decontamination. Used neutralizing liquid device 7 and decontamination pipeline system 8.

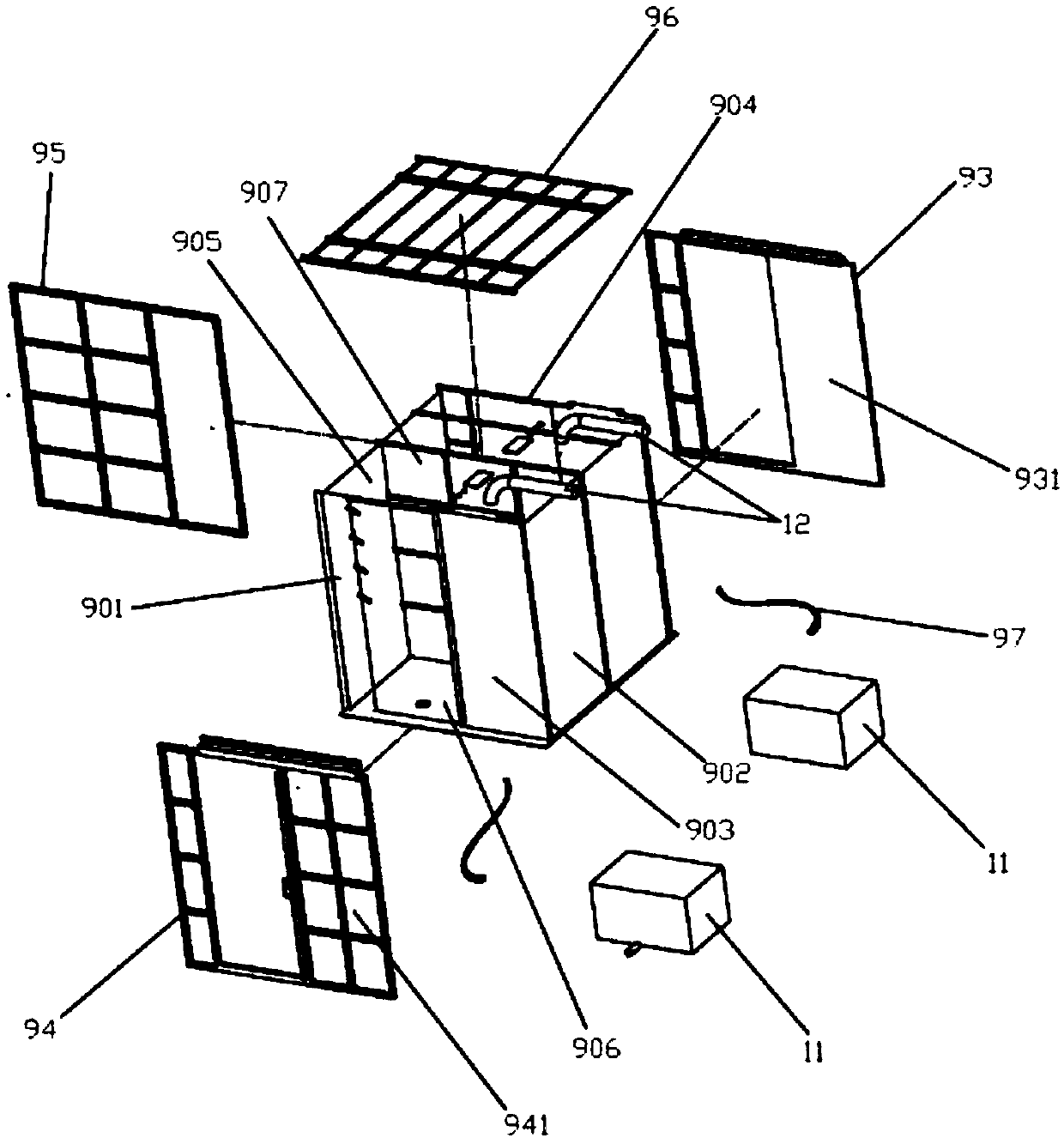

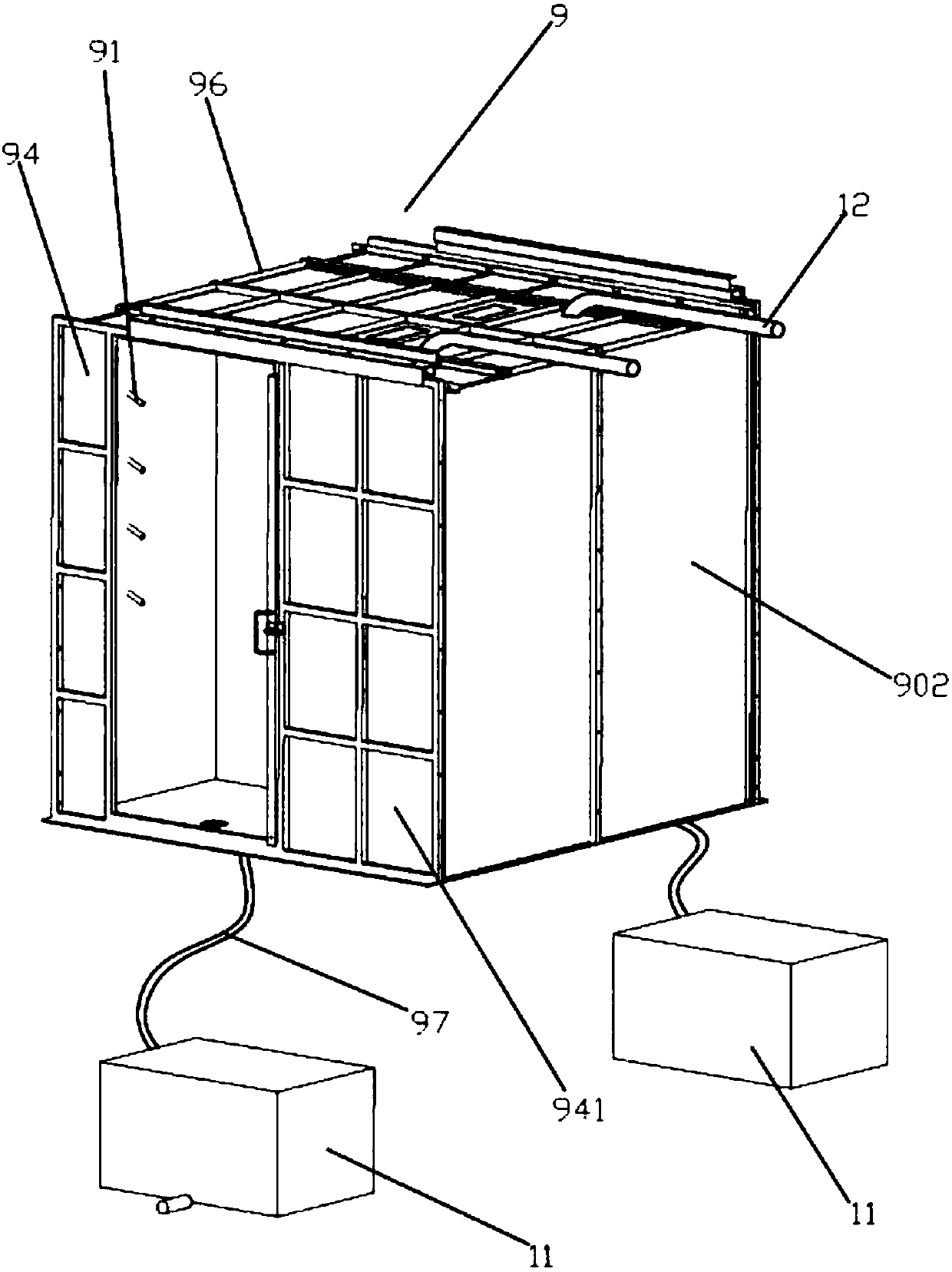

[0061] Such as figure 1 and figure 2 As shown, the chemical decontamination chamber 9 includes a decontamination chamber skeleton assembly, a front sealing plate 901 and a rear sealing plate 902, a left sealing plate 903 and a right sealing plate 904, a top plate 905 and a bottom plate 906, and a middle partition plate respectively arranged oppositely. 907, the middle partition 907 divides the chemical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com