Environmental-friendly furnace gas temperature reduction dust removing device for waste acid treatment pyrolysis furnace

A waste acid treatment and dedusting device technology, which is applied in the direction of gas fuel, heat exchanger type, chemical/physical process, etc., can solve the problems of poor dust prevention effect and high temperature of cracking furnace, so as to avoid waste of resources and prevent dust from entering cracking Effects inside the furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

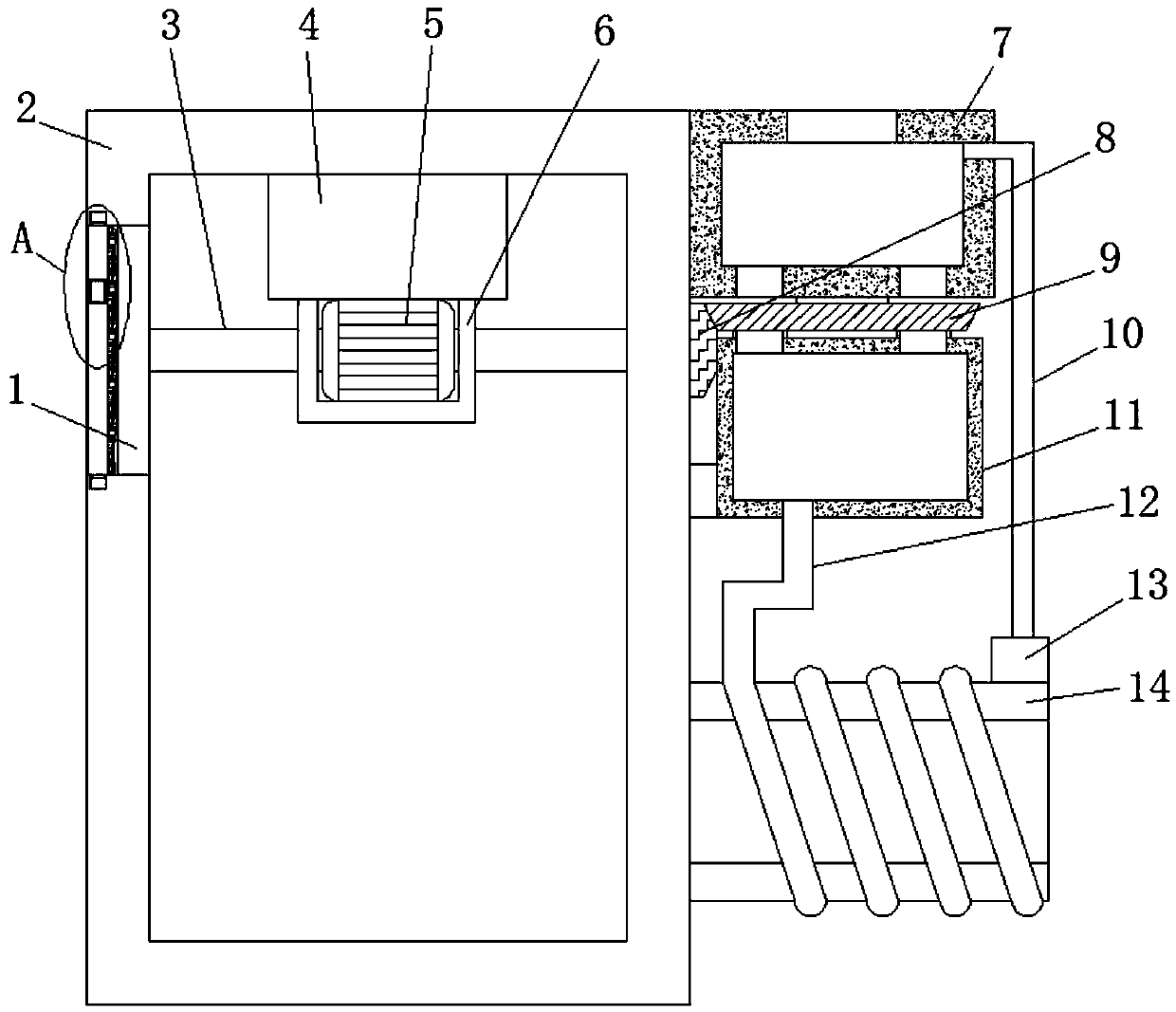

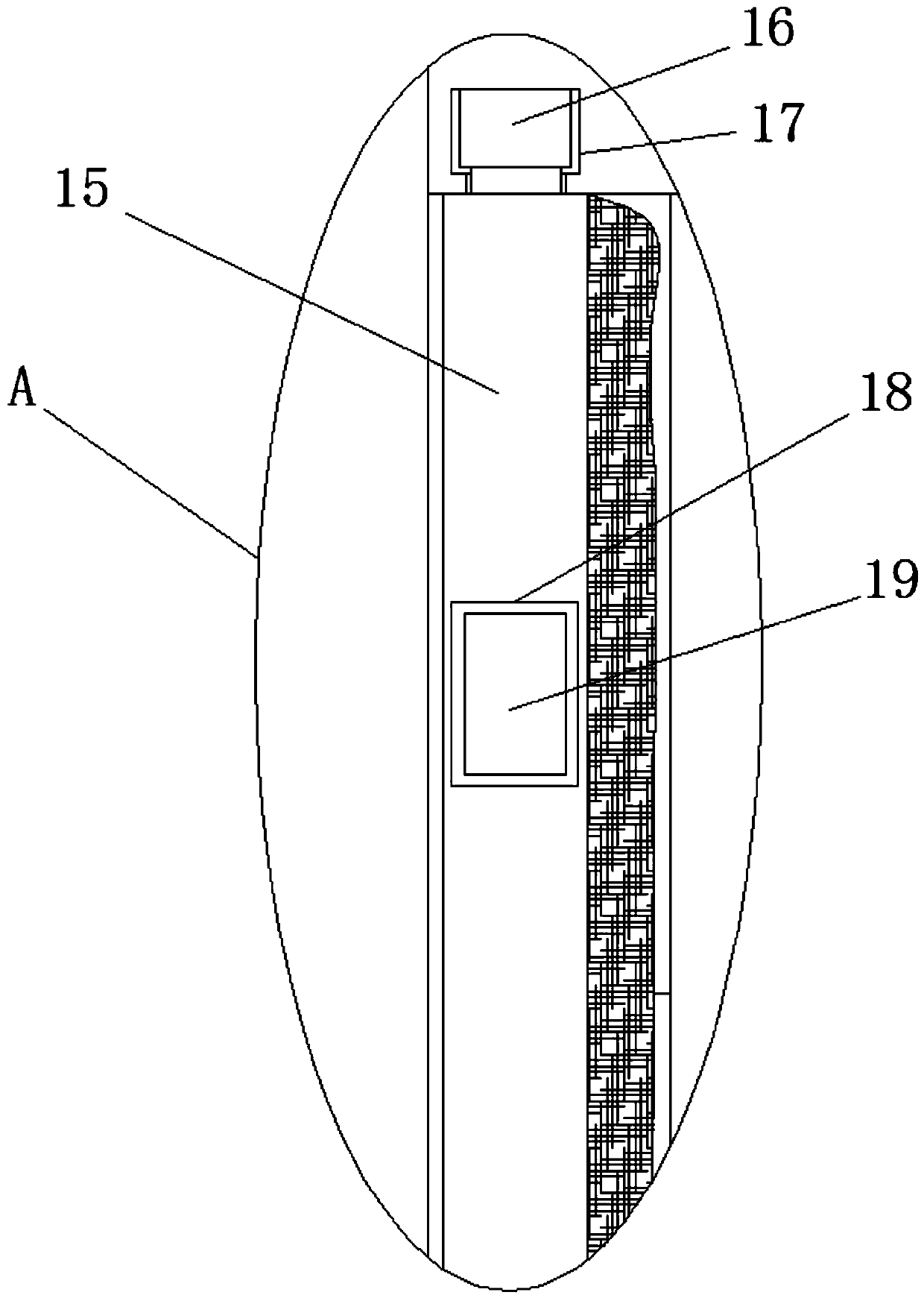

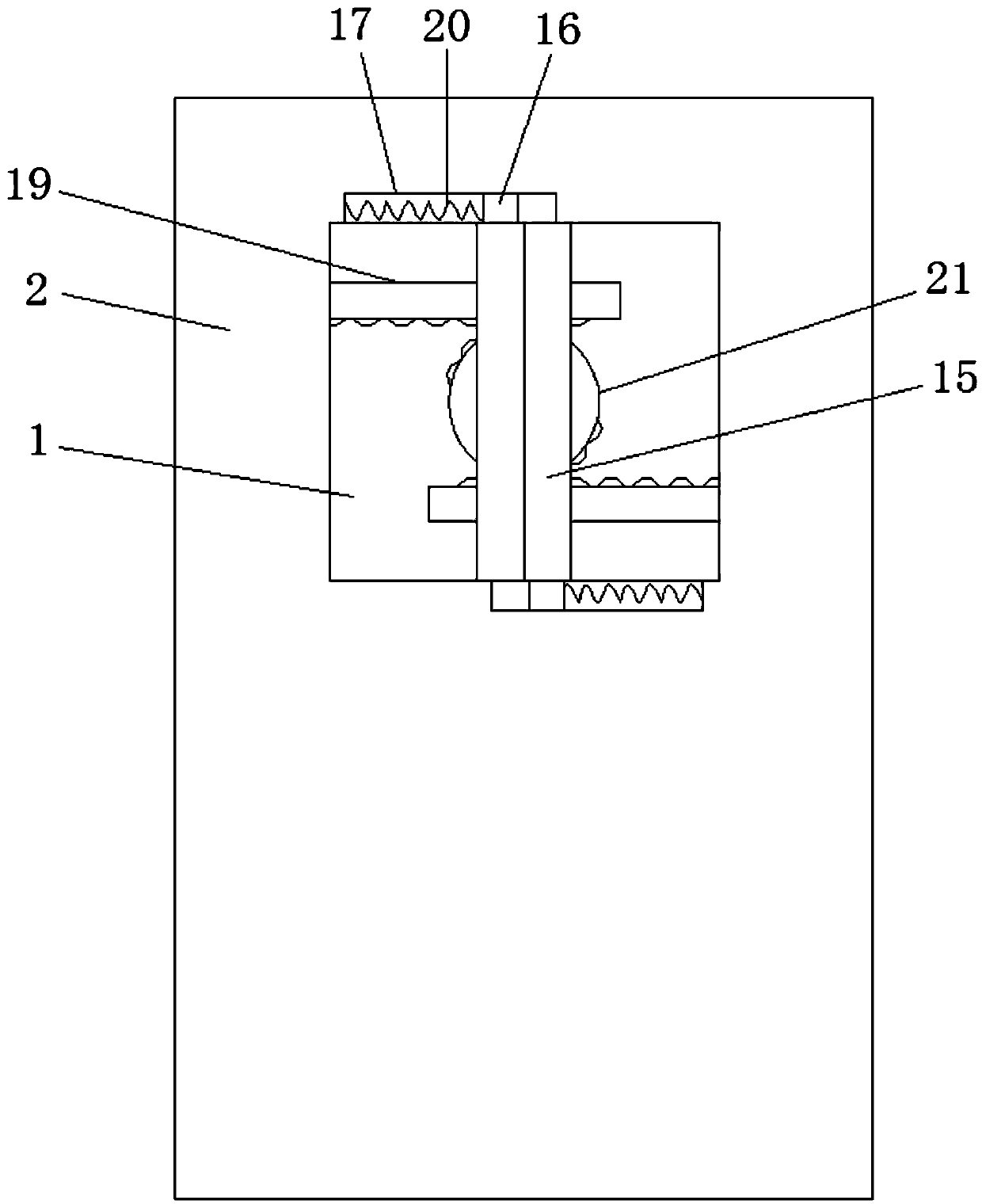

[0022] Embodiment: when in use, gas enters in the cracking furnace body 2 through the air inlet 1, and the gas is filtered through the filter plate, and then the biaxial motor 5 is started, so that the biaxial motor 5 drives the two rotating rods 3 to rotate, The rotating rod 3 drives the second gear plate 21 to rotate, and the tooth block on the second gear plate 21 meshes with the tooth block on the rack plate 19, so that the rack plate 19 drives the scraper plate 15 to clean the dust on the filter plate. And the scraper 15 drives the stop block 16 to slide in the stop slot 17, and pulls the spring 20. When the tooth block on the second gear plate 21 is separated from the tooth block on the rack plate 19, the elastic force of the spring 20 makes The limiting block 16 slides backwards in the limiting groove 17, and drives the scraper 15 to clean the filter plate again. When the biaxial motor 5 starts, the rotating rod 3 at the other end will drive the first gear plate 8 to rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com