Device and method for decomposing liquid chemical weapons under microwave irradiation

A chemical weapon and microwave generating device technology is applied in the field of devices for decomposing liquid chemical weapons under microwave irradiation to achieve the effect of avoiding leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

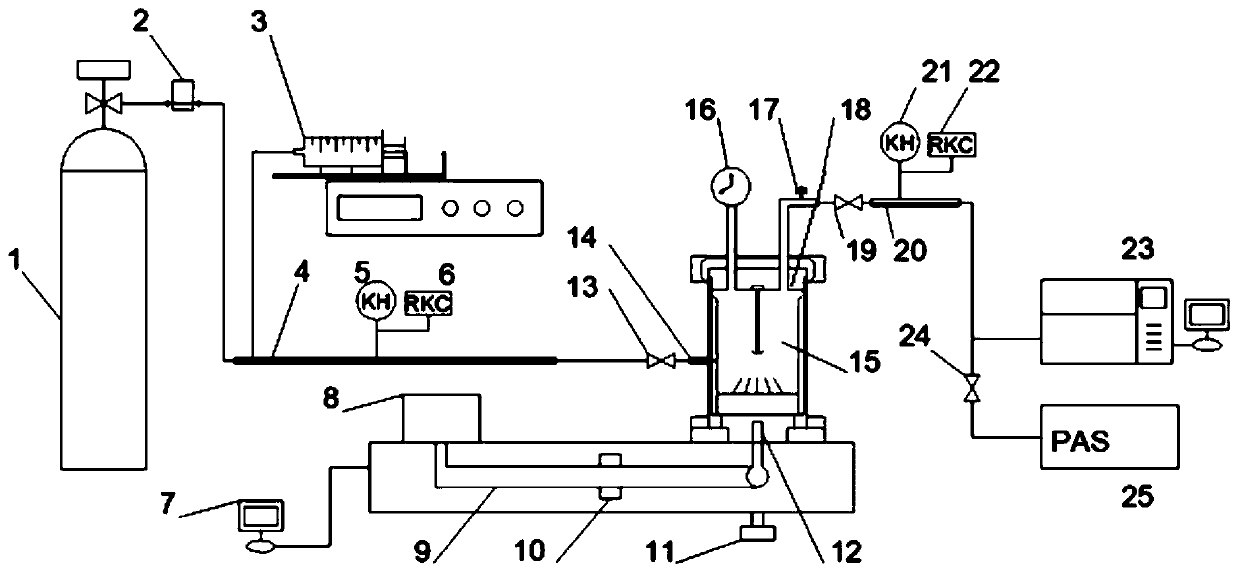

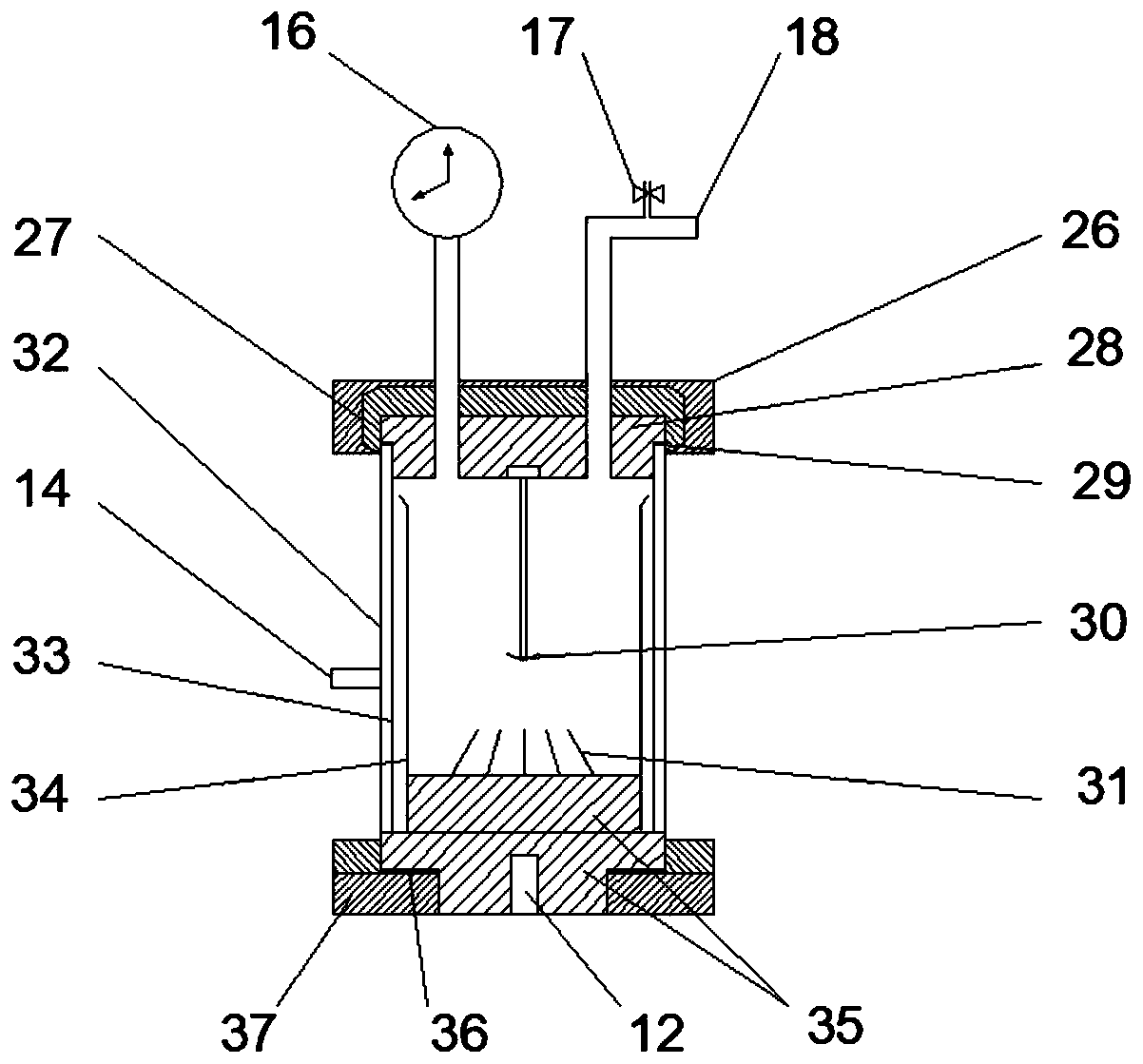

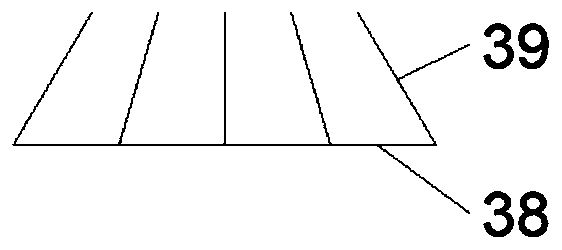

[0057] A device for decomposing liquid chemical weapons under microwave irradiation, comprising a gas cylinder 1, an automatic injector 3, a reactor 15, and a microwave generating device. The gas cylinder 1 is connected to the air inlet 14 of the reactor 15 through an air inlet pipe, The pipeline is provided with a first heating belt 4, and the automatic injector 3 is connected to the part covered by the first heating belt 4 of the air intake pipeline. The first heating belt 4 is an electric heat tracing device located on the wall of the air intake pipeline, and the automatic injector 3 inputs poison liquid. The poison liquid and the carrier gas input by the gas cylinder 1 are mixed in the intake pipe and heated by the first heating belt 4 to become a gas that enters the reactor 15. The lower part of the cavity of the reactor 15 is provided with a discharger 31, and the discharger 31 It consists of a support and several discharge metal wires. The upper side of the support is fi...

Embodiment 2

[0083] Using the above device to measure the interactive discharge process of microwave and medium under multi-physics field, the process is as follows:

[0084] Take wire tungsten as the target material, put the wire into the quartz lining 34, seal the reactor 15, open the third shut-off valve 13, close the fourth shut-off valve 17, open the first shut-off valve 19, and open the gas cylinder 1 valve Put in the carrier gas for 2 minutes, turn on the water load 10 to carry out water circulation, set the microwave power to 900W, turn on the microwave preheating, and then turn on the microwave generator. After the microwave works for 1 minute, you can hear the crackling sound of metal discharge. After 2 minutes, wait for the metal to discharge When it tends to be stable, close the first cut-off valve 19, open the automatic injector 3 and the first heating belt 4, and set different carrier gas flow rates and poison flow rates for different poisons, so that the poisons can be comple...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com