Application of 1,3,4-thiadiazole compounds in sulfide ore flotation

A technology of thiadiazoles and compounds, which is applied in the field of high-efficiency and high-separation flotation agents, can solve the problems of high pH requirements for flotation pulp, difficulty in effectively removing pyrite from concentrates, and poor selective collection capacity. , to achieve good flotation selectivity and recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The 1,3,4-thiadiazole compound (in formula 1, R 1 , R 2 Respectively hydrogen, n-hexyl), ethyl sodium xanthate, 2 # Add the oil into 1L of deionized water (concentration: 0.1mol / L) at the ratio of 0.075mol: 0.020mol: 0.005mol, stir magnetically at 40°C for 30min to fully mix the medicine, and seal it for use.

[0049] Lead-zinc sulfide ore from a factory in South China is used as the raw ore, and the metal grades of the raw ore are Fe: 28.3%, Pb: 3.8%, and Zn: 5.5%. Wet grind the raw ore for 4 minutes to make the particle size less than 0.074mm.

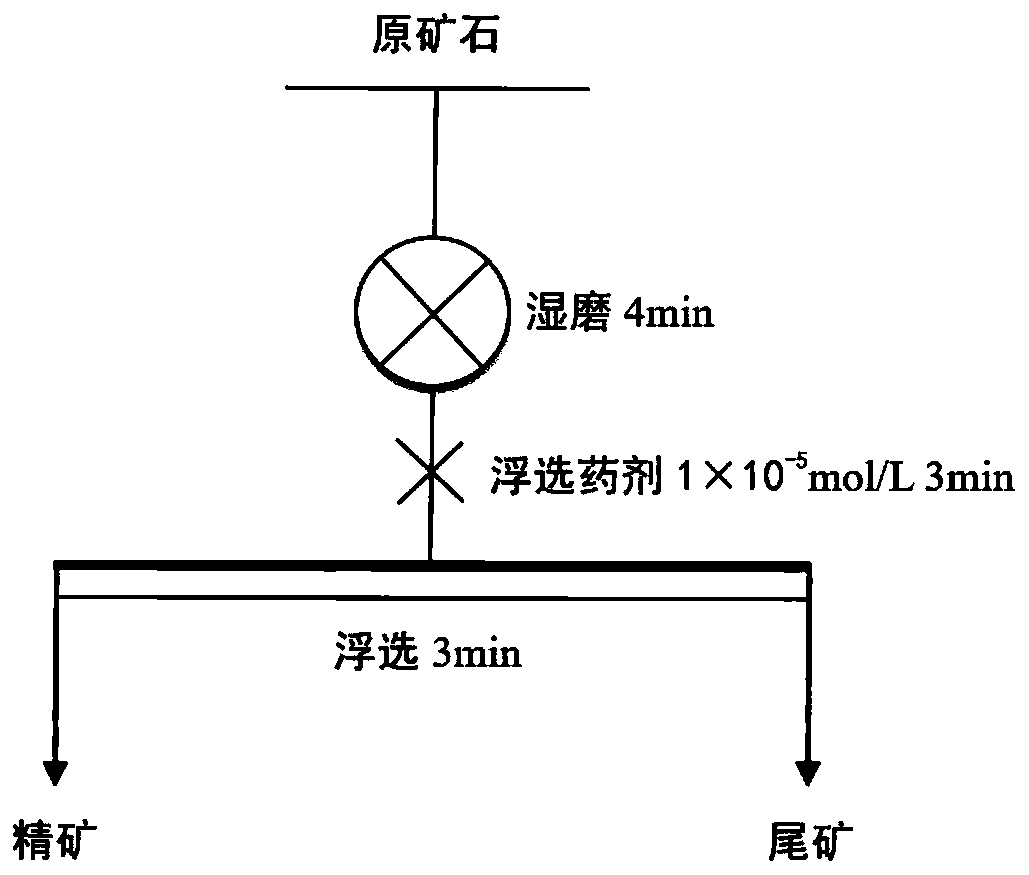

[0050] Grinding 500g raw ore (the pH of the grinding is 8, the particle size before ball milling is 0.150-0.074mm, and the particle size after ball milling is not more than 0.074mm, using a conical ball mill for wet grinding, and the grinding concentration is 35-40%), using figure 1 The process shown is carried out in a 1.5L flotation machine for flotation experiments. The raw ore (0.150-0.074mm) is wet-milled for 4 minutes...

Embodiment 2

[0056] The 1,3,4-thiadiazole compound (in formula 1, R 1 , R 2 Hydrogen group, ethyl group), ethyl sodium xanthate, and terpineol were added to 1L deionized water (concentration: 0.1mol / L) at a ratio of 0.080mol:0.015mol:0.005mol, and magnetically stirred at 40°C for 30min , so that the agent is fully mixed, and sealed for use.

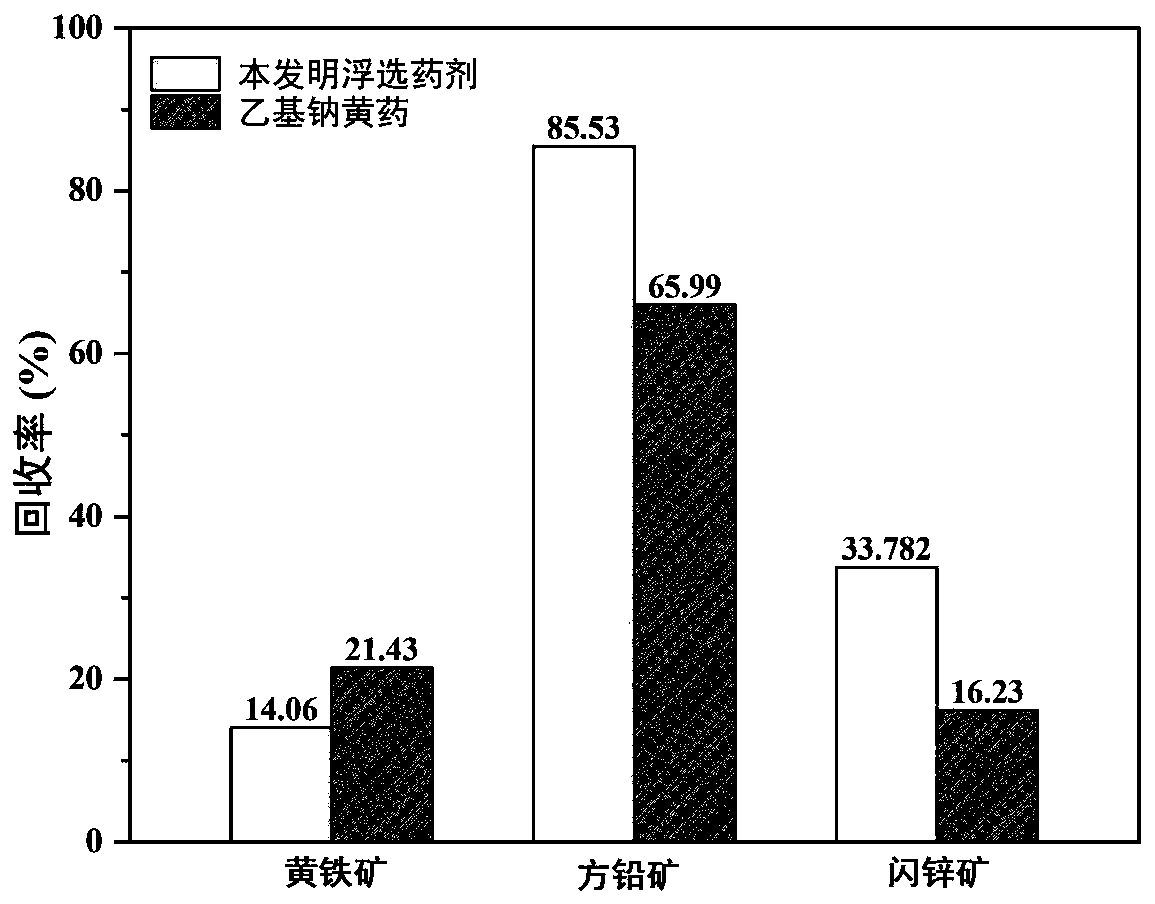

[0057] Concentrates of pyrite, galena and sphalerite in South China are used. use Figure 4 The process shown in the experiment is divided into two groups, and the flotation agent of ethyl sodium xanthate is used as the flotation agent to compare with the flotation agent compounded in this case. Sodium xanthate replaces the compound flotation agent in this case, so as to compare the flotation effect of ethyl sodium xanthate and flotation agent in this case.

[0058] The concentrate ore (with a particle size of 3mm-0.5mm) was dry-milled for 15 minutes (the particle size after grinding was 0.0740-0.0374mm, the grinding pH of pyrite was 6, the grindi...

Embodiment 3

[0062] The 1,3,4-thiadiazole compound (in formula 1, R 1 , R 2 Hydrogen group, phenyl group), ethyl sodium xanthate, and terpineol were added into 1L deionized water (concentration: 0.1mol / L) at a ratio of 0.085mol:0.010mol:0.005mol, and magnetically stirred at 40°C for 30min , so that the agent is fully mixed, and sealed for use.

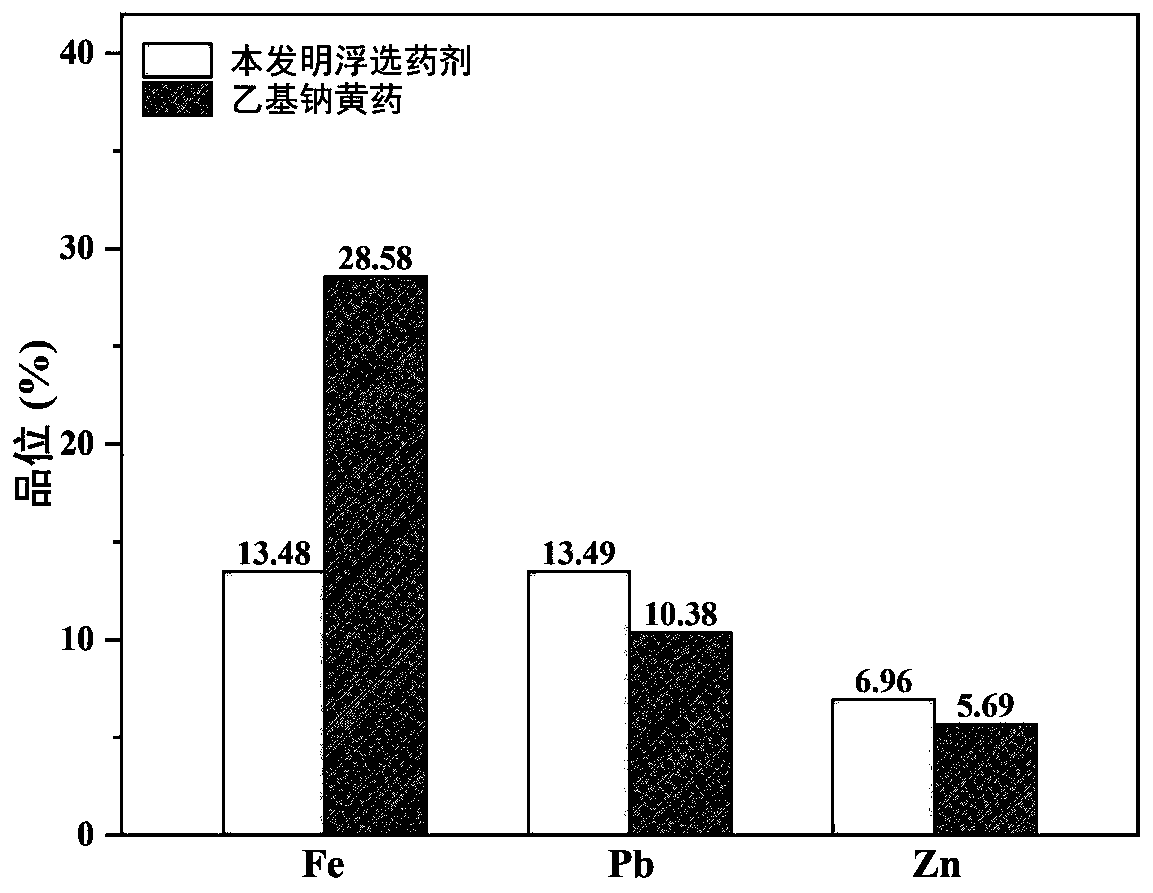

[0063] Concentrates of pyrite, galena and sphalerite in South China are used. Figure 6 The process shown in the experiment is divided into two groups, and the flotation agent of ethyl sodium xanthate is used as the flotation agent to compare with the flotation agent compounded in this case. Sodium xanthate replaces the compound flotation agent in this case, so as to compare the flotation effect of ethyl sodium xanthate and the prepared flotation agent in this case.

[0064] The specific operation is: dry-grind the concentrate ore (with a particle size of 3mm-0.5mm) for 15 minutes (the particle size after grinding is 0.0740-0.0374mm), in which t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com