Inner cavity iron ball magnetic suspension type pneumatic artificial muscle

A pneumatic artificial muscle and pneumatic muscle technology, applied in the field of pneumatic muscles, can solve the problems of rubber tubes that are difficult to support pneumatic muscles, slow inflation and deflation, and large gas consumption, so as to save flow, prevent normal inflation and deflation, and accelerate deflation The effect of air velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

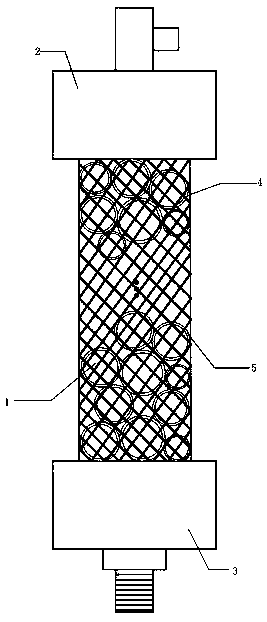

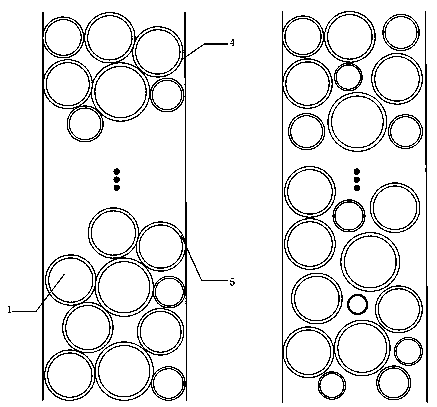

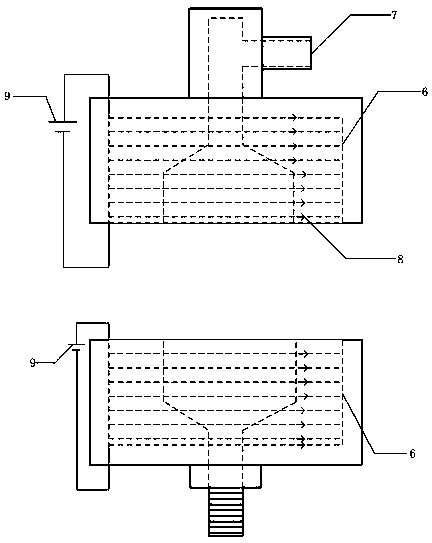

[0022] The embodiment of the present invention discloses an inner cavity iron ball magnetic suspension type pneumatic artificial muscle. For details, please refer to Figures 1~5 , this embodiment includes a hollow iron balloon 1 wrapped by a rubber membrane, an upper pneumatic muscle joint 2, a lower pneumatic muscle joint 3, a thin-walled rubber membrane 4, a gas higher than atmospheric pressure 5, an electromagnetic coil 6, an inlet / outlet 7, Current direction 8, switching power supply 9; in this embodiment, the pneumatic muscle is an independently designed pneumatic muscle, and the hollow iron balloon 1 and the electromagnetic coil 6 are all available on the market; the thin-walled rubber membrane 4. Wrap it outside the hollow iron balloon 1, and fill the rubber membrane with gas 5 higher than atmospheric pressure. Put the hollow iron balloon 1 wrapped with the thin-walled rubber membrane 4 into the inner cavity of the pneumatic muscle until it is basically filled. cavity;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com