A kind of underwater sound absorption rubber composite material and preparation method thereof

A composite material and sound-absorbing rubber technology, applied in the field of underwater sound-absorbing materials, can solve the problems of difficulty in meeting the use requirements of underwater sound-absorbing rubber products, low sound absorption coefficient, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

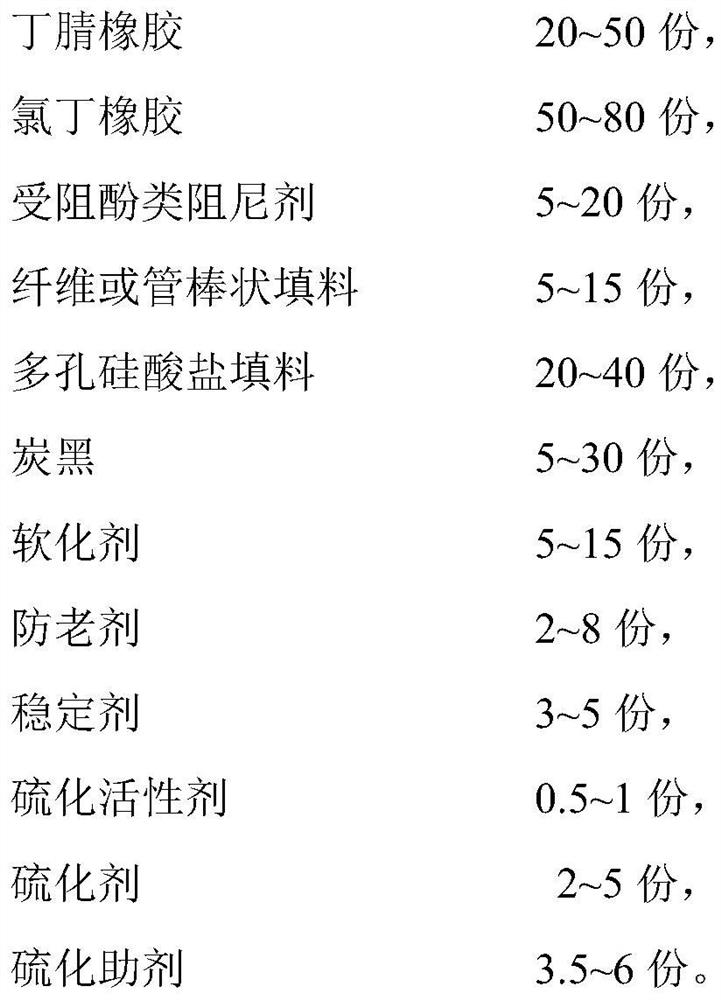

Method used

Image

Examples

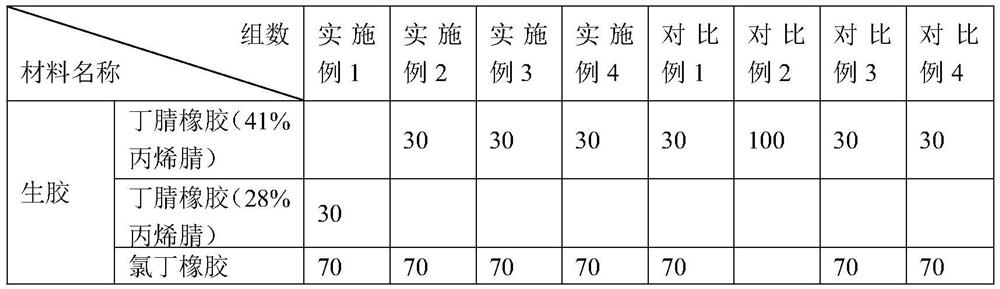

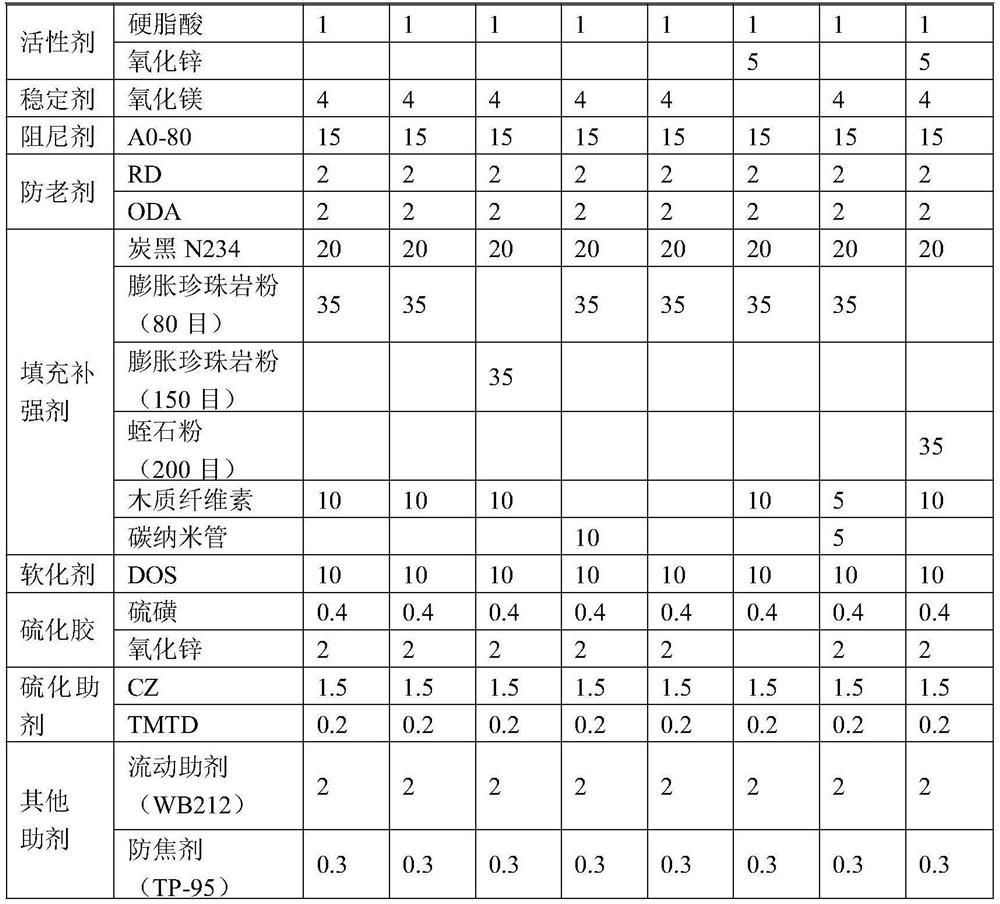

Embodiment 1

[0038] The preparation method of the underwater sound-absorbing rubber composite material in this embodiment, the steps are as follows:

[0039] Raw materials are equipped according to Table 1, nitrile rubber (acrylonitrile content 28%), neoprene rubber, stearic acid, magnesium oxide, hindered phenol damping agent A0-80, carbon black, expanded perlite powder (80 mesh), wood Cellulose, DOS and flowable dispersant WB212 were put into the internal mixer for mixing, the mixing temperature was 140°C, and the mixing time was 5 minutes; then the materials were fed into the open mixer, and the open mixer was used for thin pass, roll The gap is 1mm, thin pass about 5 times, until the brown-yellow fiber visible to the naked eye disappears, then put the mixed rubber into the internal mixer, add vulcanizing agent, vulcanizing aid and anti-scorch agent, and mix at below 90 ° C. Refining for 2 minutes, discharging, unloading, cooling, and parking for 16 hours to obtain the mixed rubber; vul...

Embodiment 2

[0042] The preparation method of the underwater sound-absorbing rubber composite material in this embodiment, the steps are as follows:

[0043] Raw materials are equipped according to Table 1, nitrile rubber (acrylonitrile content 41%), neoprene rubber, stearic acid, magnesium oxide, hindered phenol damping agent A0-80, carbon black, expanded perlite powder (80 mesh), wood Cellulose, DOS and flowable dispersant WB212 were put into the internal mixer for mixing, the mixing temperature was 140°C, and the mixing time was 5 minutes; then the materials were fed into the open mixer, and the open mixer was used for thin pass, roll The distance is 1mm, thin pass about 5 times, until the brown-yellow fiber visible to the naked eye disappears, then put the mixed rubber into the internal mixer, add vulcanizing agent, vulcanizing aid and anti-scorch agent CTP, and keep the temperature below 90°C Mixing for 2 minutes, discharging, unloading, cooling, and parking for 16 hours to obtain the...

Embodiment 3

[0046] The preparation method of the underwater sound-absorbing rubber composite material in this embodiment, the steps are as follows:

[0047] Raw materials are equipped according to Table 1, with nitrile rubber (41% acrylonitrile content), 70 parts of neoprene, stearic acid, magnesium oxide, hindered phenol damping agent A0-80, carbon black, expanded perlite powder (150 mesh) , lignocellulose, DOS and flow dispersant WB212 are put into the internal mixer for mixing, the mixing temperature is 140°C, and the mixing time is 5 minutes; then the materials are fed into the open mixer, and the thin pass is carried out using the open mixer , the roller distance is 1mm, thin pass about 5 times, until the brown-yellow fiber visible to the naked eye disappears, then put the mixed rubber into the internal mixer, add vulcanizing agent, vulcanization aid and anti-scorch agent CTP, at 90 Mix for 2 minutes below ℃, discharge, release, cool, and park for 16 hours to obtain the mixed rubber;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com