Active silencer

A muffler and active technology, applied in the direction of sound absorption, noise reduction devices, engine components, etc., can solve the problems of inability to achieve sound absorption effect and adjustment of sound absorption performance, and achieve simple structure, improve sound absorption effect, and reduce energy The effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

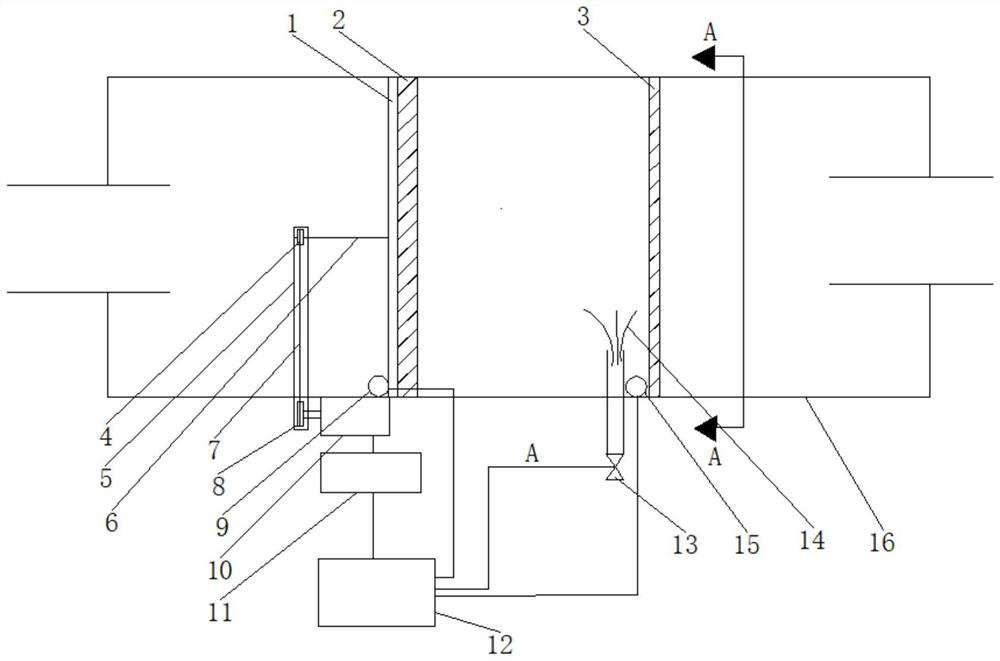

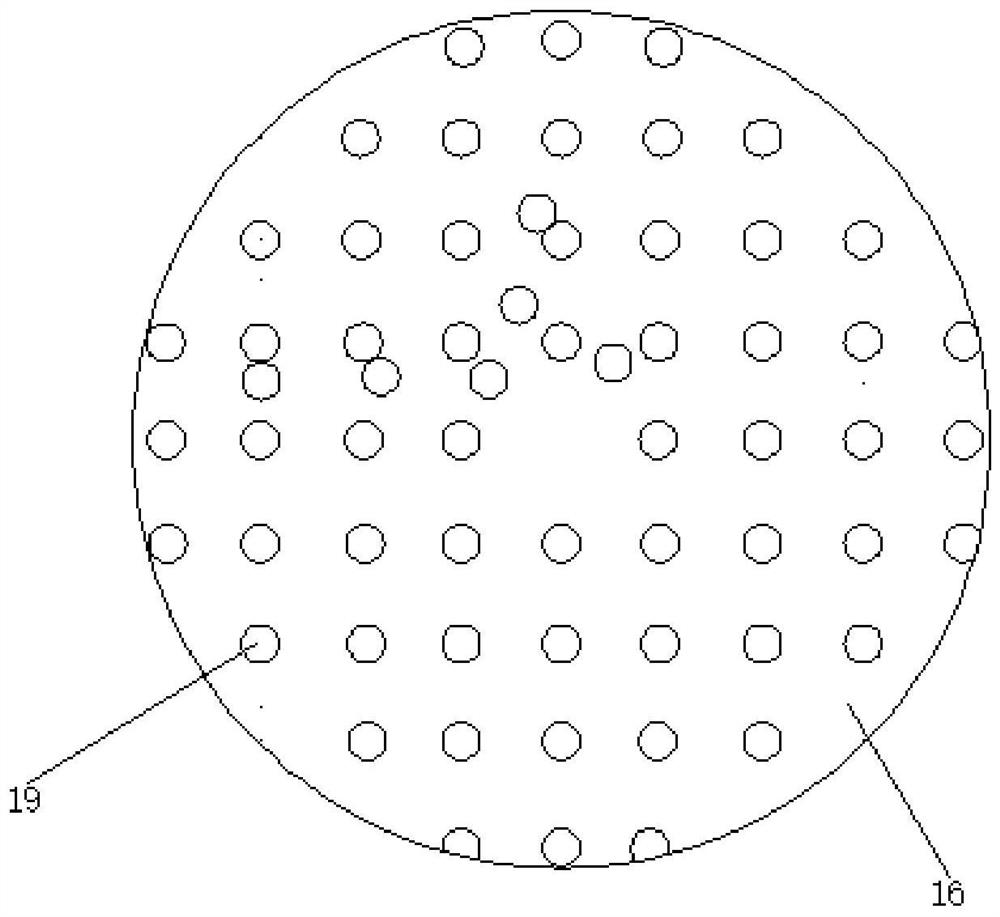

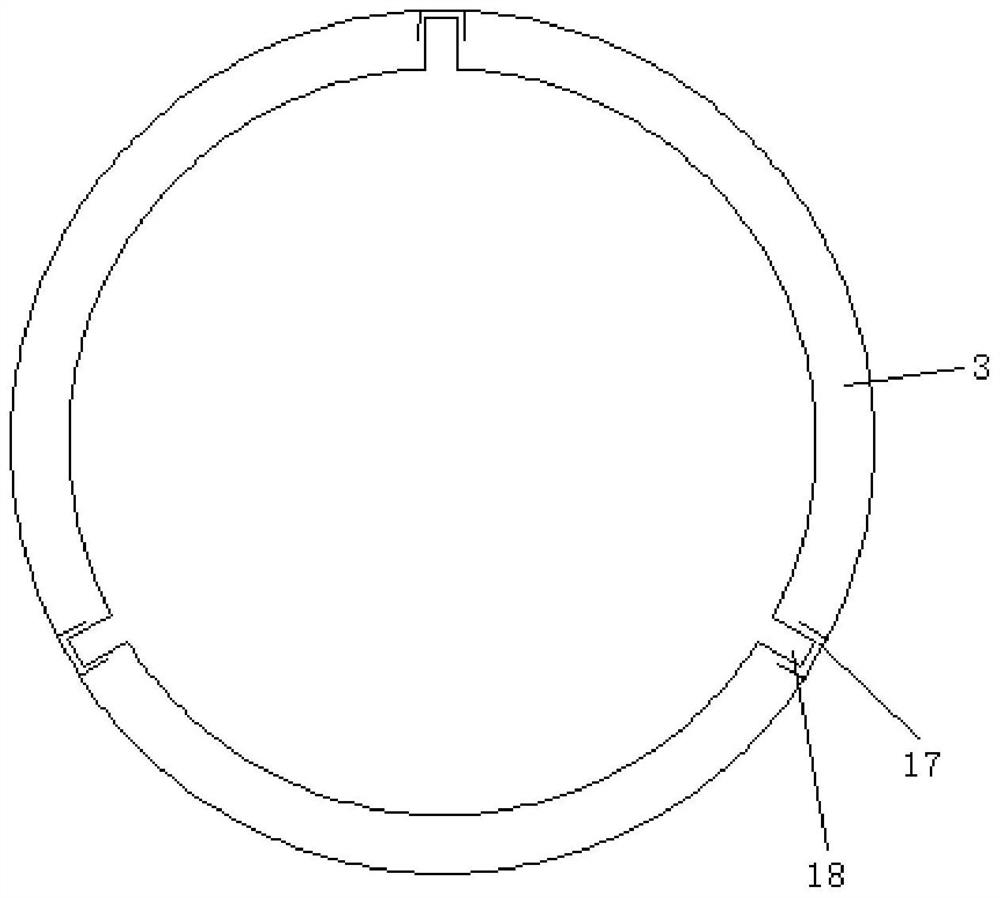

[0031] The invention provides an active muffler, specifically as Figure 1 to Figure 3 As shown, it includes a shell 16 and a motor 10 with a circular cross section, and adjacent baffles 1 and porous material layers 2 are sequentially installed inside the shell 16 along its axial direction; in order to ensure the use effect and ease of use, in this embodiment , the shell 16 is a circular metal cylinder, the motor 10 is a stepper motor, and the porous material layer 2 is a composite rock wool board.

[0032] The porous material layer 2 is sealed and connected with the inner wall of the shell 16; the baffle plate 1 and the inner wall of the shell 16 are fitted in a gap, and a rotating shaft 6 is installed in the center, and a number of airflow holes 19 matching with the porous material layer 2 are randomly opened on the baffle plate 1; The motor 10 is arranged on the outer wall of the casing 16, the end of the output shaft is connected with the first pulley 8, the front end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com