A metal powder-rubber particle composite phonon material, preparation method and application

A technology of rubber particles and metal powder, which is applied in the direction of sound-generating devices and instruments, can solve the problems of limited material thickness, little practicality, complex structure, etc., and achieve high-efficiency absorption of low-frequency sound, excellent sound absorption characteristics, and high sound absorption coefficient Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

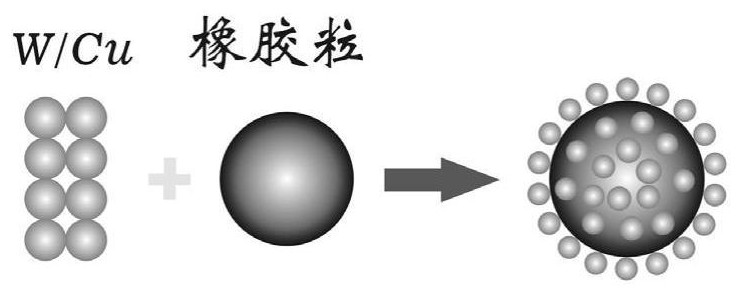

[0045] A metal powder-rubber particle composite phonon material,

[0046] Including rubber particles, and metal powder coated on the surface of the rubber particles;

[0047] Wherein, the metal powder adheres to the surface of the rubber particles through an adhesive to form an elastic sphere with a core-shell structure;

[0048] The particle size of the rubber particles is 0.6mm;

[0049] The thickness of the metal powder adhering to the surface of the rubber particles through an adhesive is 0.45 mm;

[0050] The particle size of the metal powder is 50 mesh;

[0051] The metal powder-rubber particle composite phonon material described above is prepared according to the following preparation method, see figure 1 , including the following steps:

[0052] Weigh 0.2g of component A epoxy resin in the two-component adhesive including component A and component B and add it to 5mL of acetone to obtain A solution; use the same method to add 0.2g of component B epoxy resin Add th...

Embodiment 2

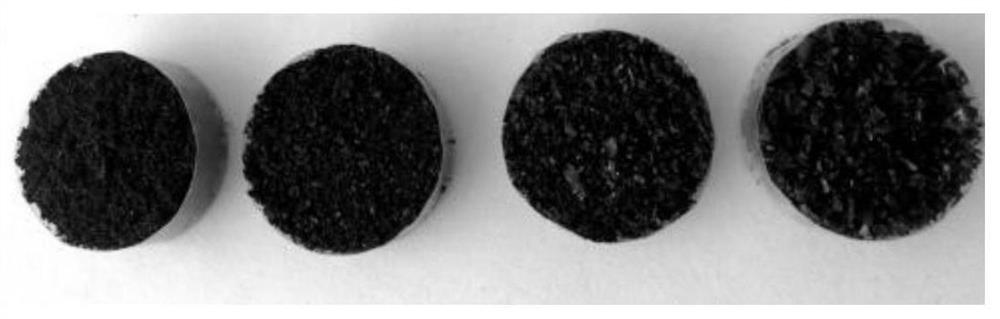

[0054] Same as Example 1, the difference is that

[0055] The particle size of the rubber particles is 1 mm.

Embodiment 3

[0057] Same as Example 1, the difference is that

[0058] The particle size of the rubber particles is 2mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com