A preparation method of three-dimensional anti-counterfeiting white cardboard

A white cardboard and three-dimensional technology is applied in the field of preparation of three-dimensional anti-counterfeiting white cardboard, and can solve the problems of the influence of the anti-counterfeiting effect of anti-counterfeiting signs and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

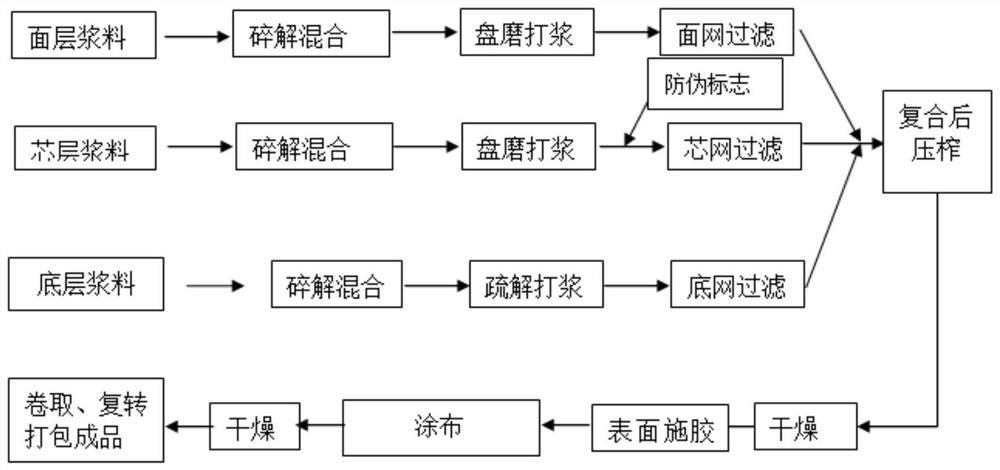

[0042] A preparation method of three-dimensional anti-counterfeiting paper, the process is as follows figure 1 shown, including the following steps:

[0043] (1) make face paper layer slurry, core paper layer slurry and face paper layer slurry respectively;

[0044] (2) loading the anti-counterfeit mark on the carrier to obtain the anti-counterfeit layer;

[0045] (3) After the surface paper layer slurry, core paper layer slurry and bottom paper layer slurry prepared in step (1) are respectively filtered, the anti-counterfeiting layer obtained in step (2) is added to the core paper layer slurry , and then perform three-layer composite to obtain a composite slurry with a thickness of 150-400 μm;

[0046] (4) After the paper sheet is formed, it is pressed and dried for the first time, then the surface is sizing, and then it is coated and dried for the second time, and then coiled and packaged to obtain a three-dimensional anti-counterfeiting white cardboard;

[0047] The carr...

Embodiment 2

[0053] A preparation method of three-dimensional anti-counterfeiting paper, comprising the following steps:

[0054] (1) make face paper layer slurry, core paper layer slurry and face paper layer slurry respectively;

[0055] (2) loading the anti-counterfeit mark on the carrier to obtain the anti-counterfeit layer;

[0056] (3) After the surface paper layer slurry, core paper layer slurry and bottom paper layer slurry prepared in step (1) are respectively filtered, the anti-counterfeiting layer obtained in step (2) is added to the core paper layer slurry , and then perform three-layer composite to obtain a composite slurry with a thickness of 150-400 μm;

[0057] (4) After the paper sheet is formed, it is pressed and dried for the first time, then the surface is sizing, and then it is coated and dried for the second time, and then coiled and packaged to obtain a three-dimensional anti-counterfeiting white cardboard;

[0058] The carrier is glutinous rice paper.

[0059] The...

Embodiment 3

[0064] A preparation method of three-dimensional anti-counterfeiting paper, comprising the following steps:

[0065] (1) make face paper layer slurry, core paper layer slurry and face paper layer slurry respectively;

[0066] (2) loading the anti-counterfeit mark on the carrier to obtain the anti-counterfeit layer;

[0067] (3) After the surface paper layer slurry, core paper layer slurry and bottom paper layer slurry prepared in step (1) are respectively filtered, the anti-counterfeiting layer obtained in step (2) is added to the core paper layer slurry , and then perform three-layer composite to obtain a composite slurry with a thickness of 150-400 μm;

[0068] (4) After the paper sheet is formed, it is pressed and dried for the first time, then the surface is sizing, and then it is coated and dried for the second time, and then coiled and packaged to obtain a three-dimensional anti-counterfeiting white cardboard;

[0069] The carrier is glutinous rice paper.

[0070] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com