A self-resetting steel frame central support system with large clearance

A central support system, self-reset technology, applied in building types, buildings, building components, etc., can solve problems such as openings and openings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

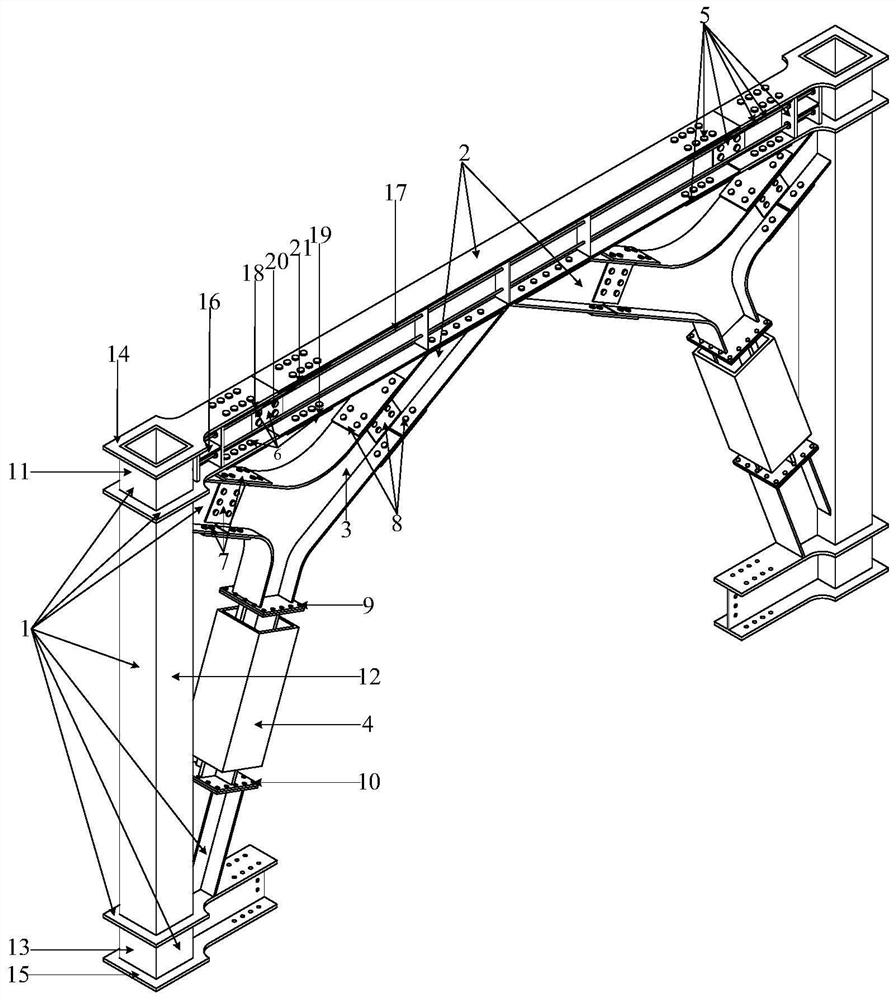

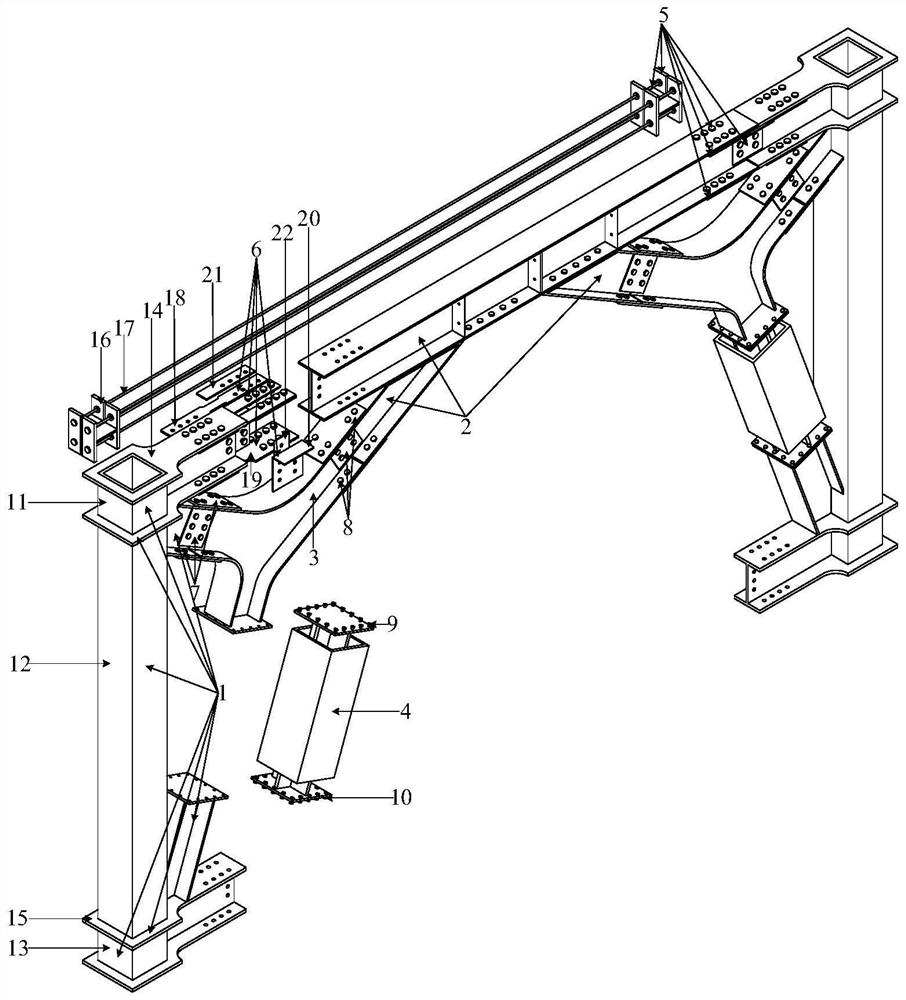

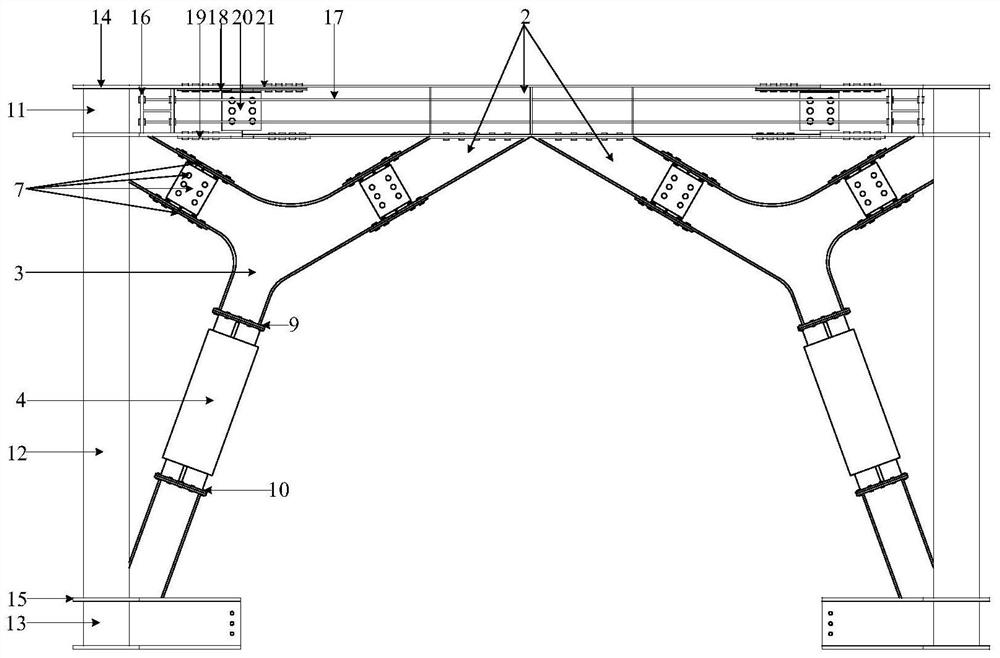

[0023] Attached below Figure 1-7 , detailing the implementation of this patent.

[0024] Such as Figure 1-7 As shown, a steel frame central support system that can open the door includes the following components:

[0025] 1——Welded combined square steel pipe column;

[0026] 2——I-beam section with oblique support rod;

[0027] 3——Y-type diagonal brace;

[0028] 4——Slant bracing energy consumption section;

[0029] 5——Combined self-resetting device;

[0030] 6 - the first connecting device;

[0031] 7 - the second connecting device;

[0032] 8 - the third connecting device;

[0033] 9 - the fourth connecting device;

[0034] 10 - the fifth connecting device;

[0035] 11——Square steel pipe upper column;

[0036] 12——Square steel pipe center column;

[0037] 13——The lower column of the square steel pipe;

[0038] 14——upper cantilever beam section;

[0039] 15——The lower cantilever beam section;

[0040] 16—tooling;

[0041] 17——prestressed cable;

[0042] 18——u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com