String bearing module and string

A technology for pipe strings and components, applied in the field of bearing components and pipe strings, which can solve the problems of inability to transmit torque, unsuitable design of pin shear value too high, poor setting ability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

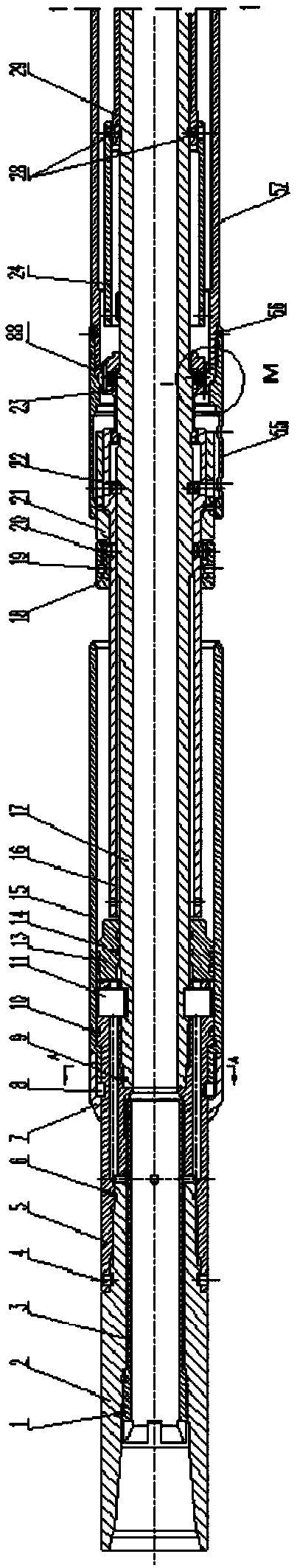

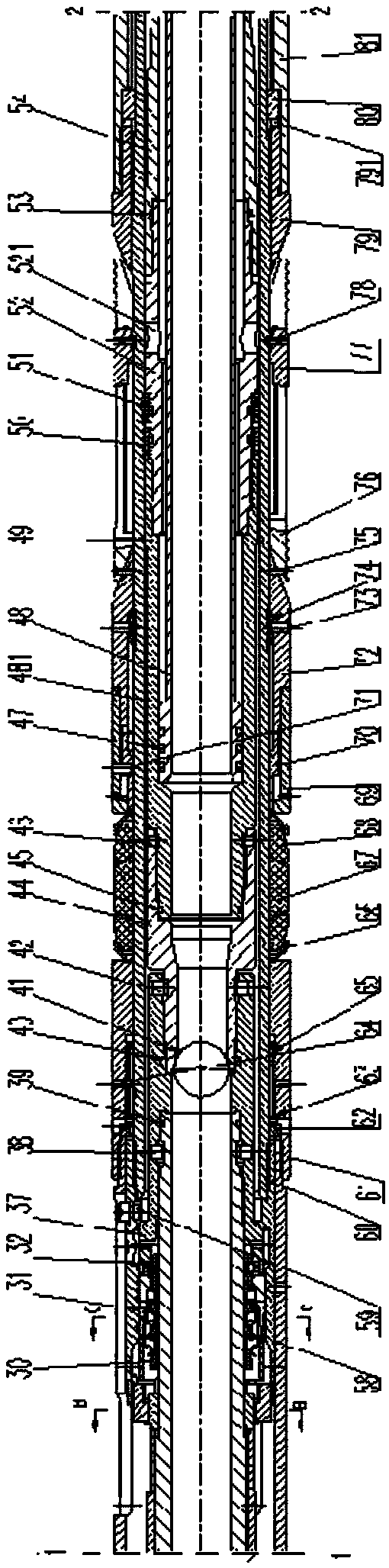

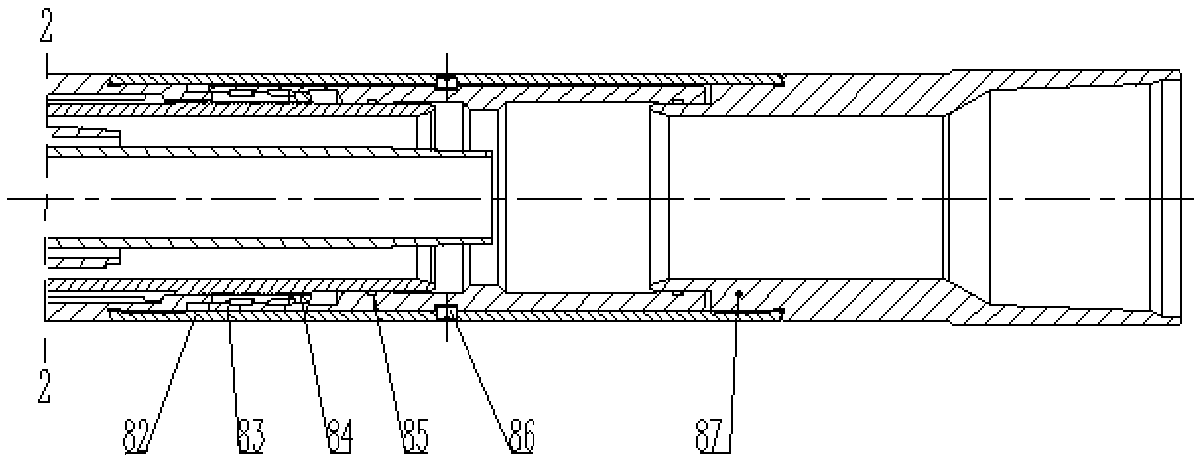

[0088] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings. In the specification, the same or similar reference numerals designate the same or similar components. The following description of the embodiments of the present invention with reference to the accompanying drawings is intended to explain the general inventive concept of the present invention, but should not be construed as a limitation of the present invention.

[0089] Unconsolidated sandstone oil and gas reservoirs are widely distributed in the world. Due to shallow burial and loose cementation, this kind of oil and gas reservoirs are very easy to produce sand during production. At present, gravel packing and simple sand control are usually used for sand control treatment, and the top packer and its setting tools are one of the key tools in gravel packing and simple sand control technology. The top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com