Gas pressurizer

A gas pressurizer and main body technology, which is applied in the direction of machines/engines, liquid variable displacement machinery, pump testing, etc., can solve the problems of slow pressurization, swelling of sealing rubber rings, difficulty in replacing rubber rings, etc., to achieve extended use The effect of life and force uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

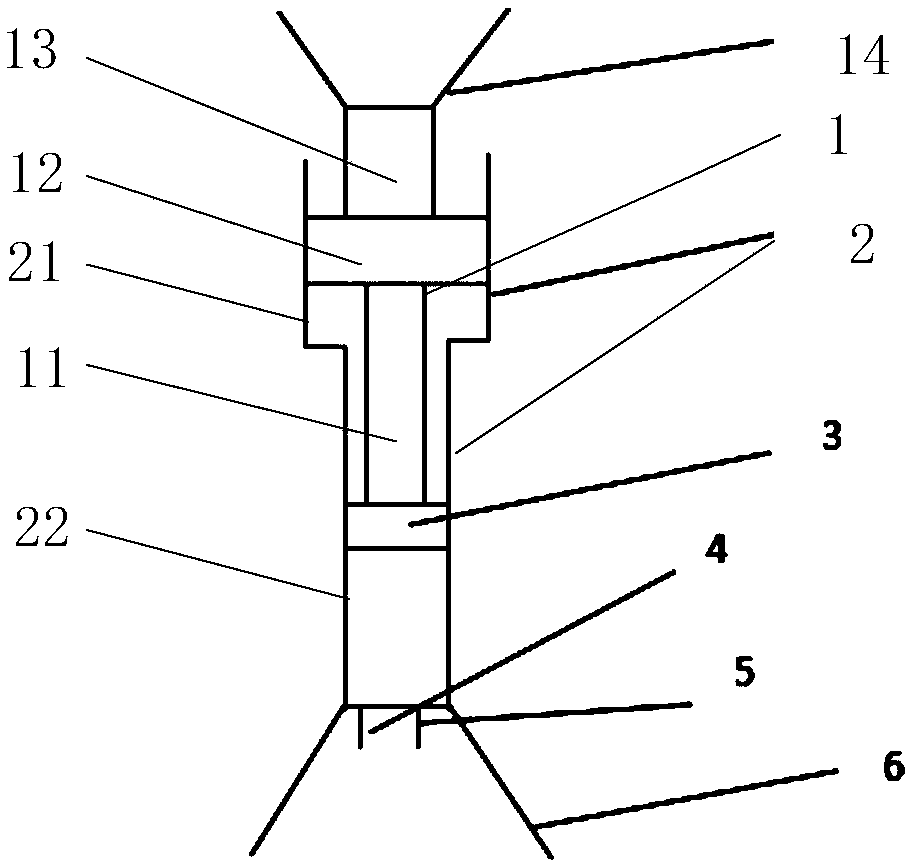

[0034] Embodiment 1 of the present invention provides a gas pressurizer, refer to figure 1 As shown, it includes: a cylinder 1, a main body 2 and a piston 3; the main body 2 is a main body with a stepped hole inside, wherein the end 21 with a larger hole is threaded (not shown in the figure); the bottom of the main body 2 is sealed and At least two gas inlets and outlets 4 and 5 are provided, and the top of the main body 2 is open; the cylinder 1 includes a piston rod 11 connected with the piston 3 and a threaded rod 12 connected with the piston rod 11, and the cross-sectional area of the threaded rod 12 is larger than that of the piston. The cross-sectional area of the rod 11; the threaded rod 12 is threadedly connected to the end 21 with the larger aperture of the main body 2; the piston 3 matches the end 22 with the smaller aperture of the main body 2; Groove (not shown in the figure), air-tight connection by rubber ring.

[0035] The traditional gas pressurization met...

Embodiment 2

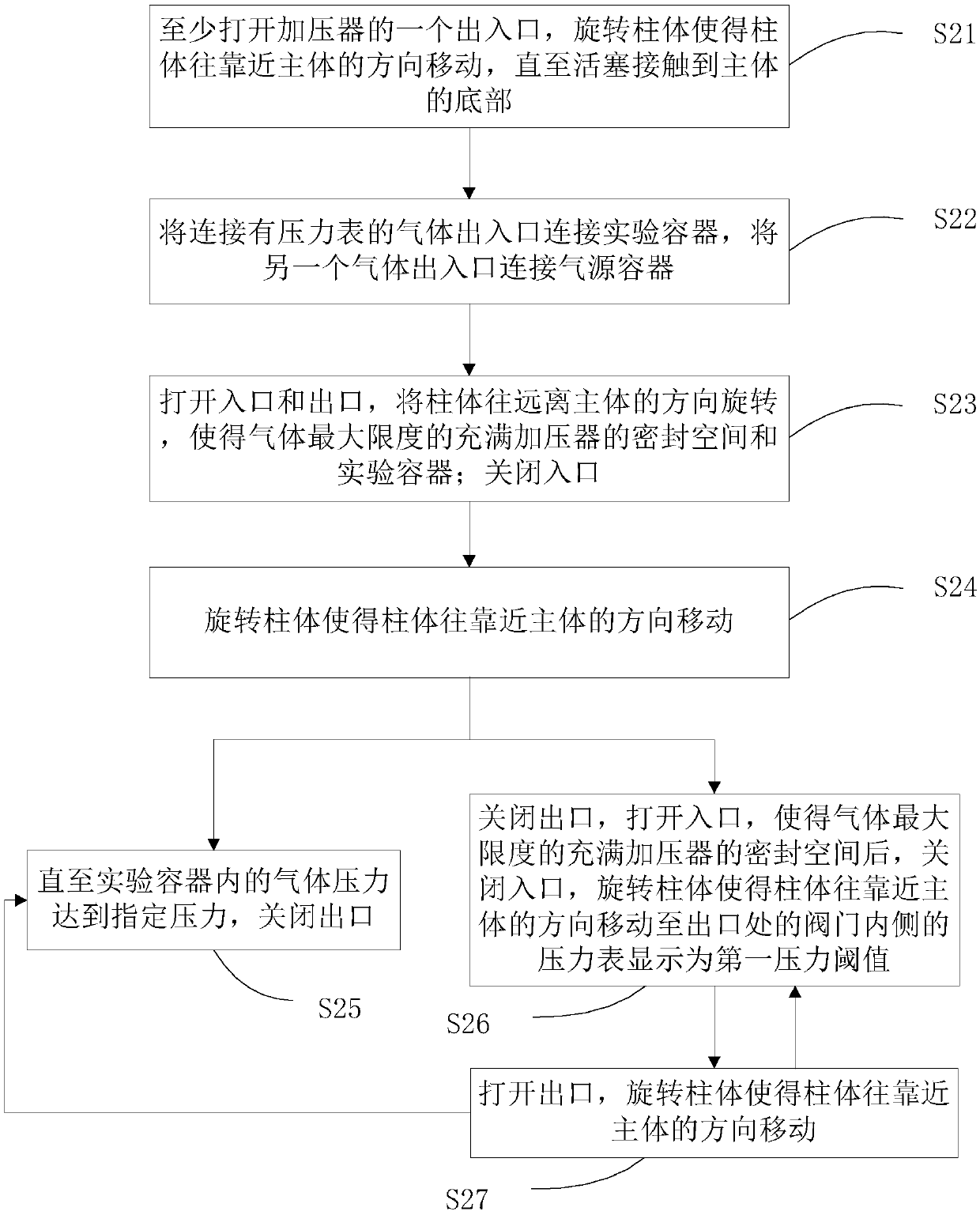

[0057] Embodiment 2 of the present invention provides a method for using the gas pressurizer described in Embodiment 1. Refer to figure 2 shown, including the following steps:

[0058] Step S21: Open at least one inlet and outlet of the pressurizer, and rotate the cylinder so that the cylinder moves toward the main body until the piston touches the bottom of the main body.

[0059] When the piston touches the bottom of the main body, all the gas in the main body can be evacuated, so as to avoid the influence of other gases on the experimental results.

[0060] Step S22: Connect the gas inlet and outlet connected with the pressure gauge to the experimental container, and connect the other gas inlet and outlet to the gas source container.

[0061] The above-mentioned gas source container, that is, the container containing the gas required for the experiment, provides the gas source for the experimental container; the gas injected into the experimental container needs to be pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Pitch | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com