A bidirectional cross-jet cooling device and cooling method thereof

A technology of jet cooling and jet device, which is applied in the field of heat treatment to achieve high stability, convenient installation and enhanced heat exchange capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

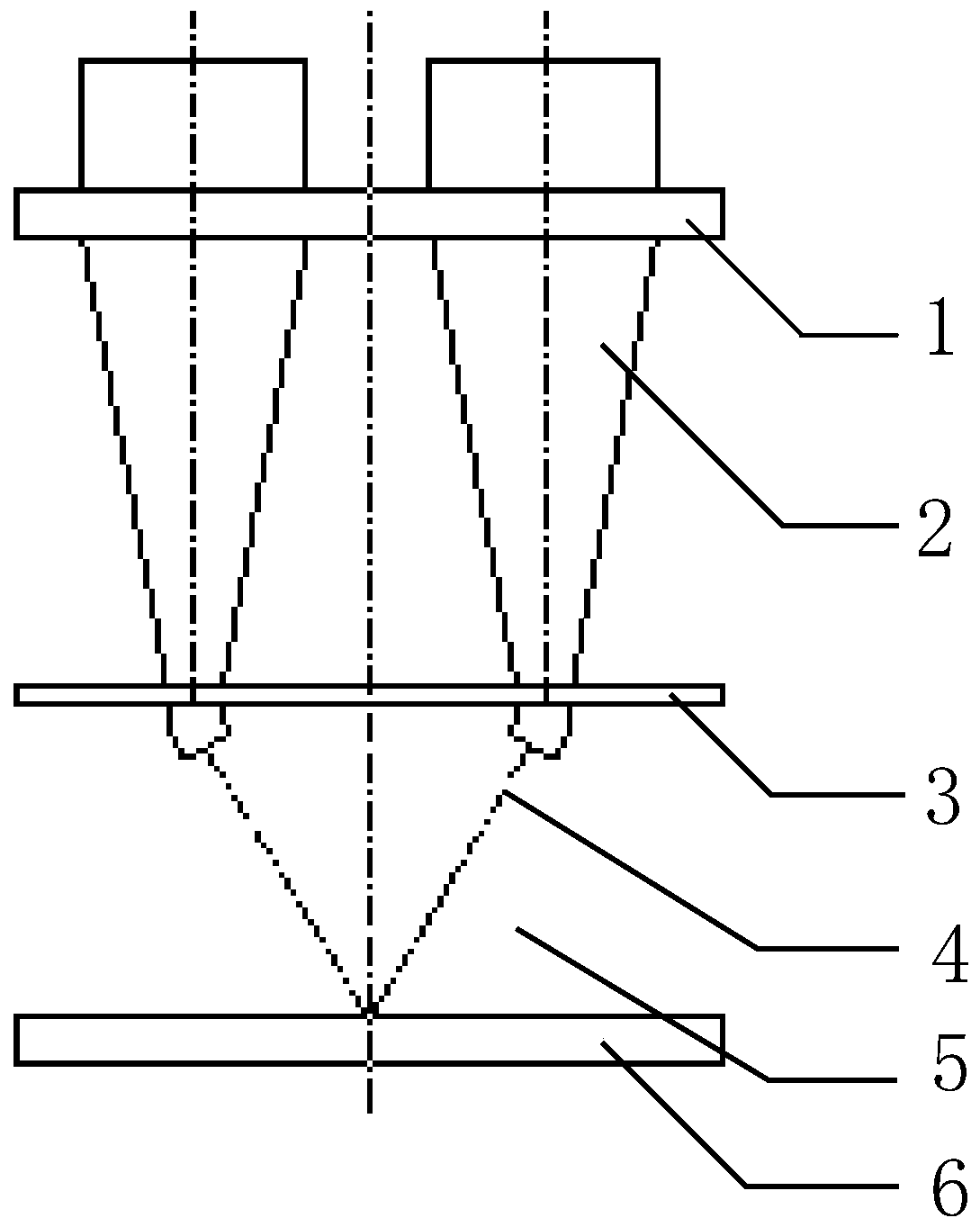

Method used

Image

Examples

Embodiment

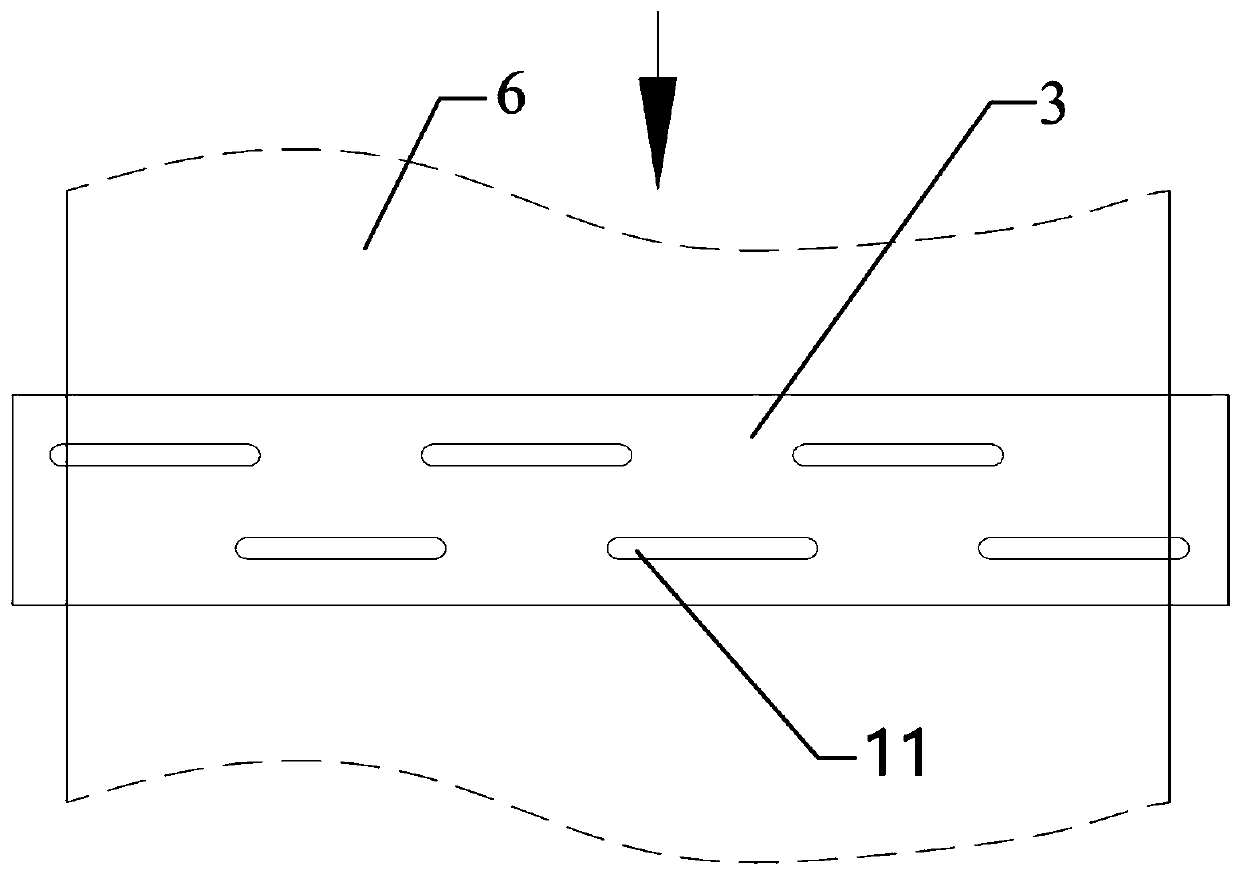

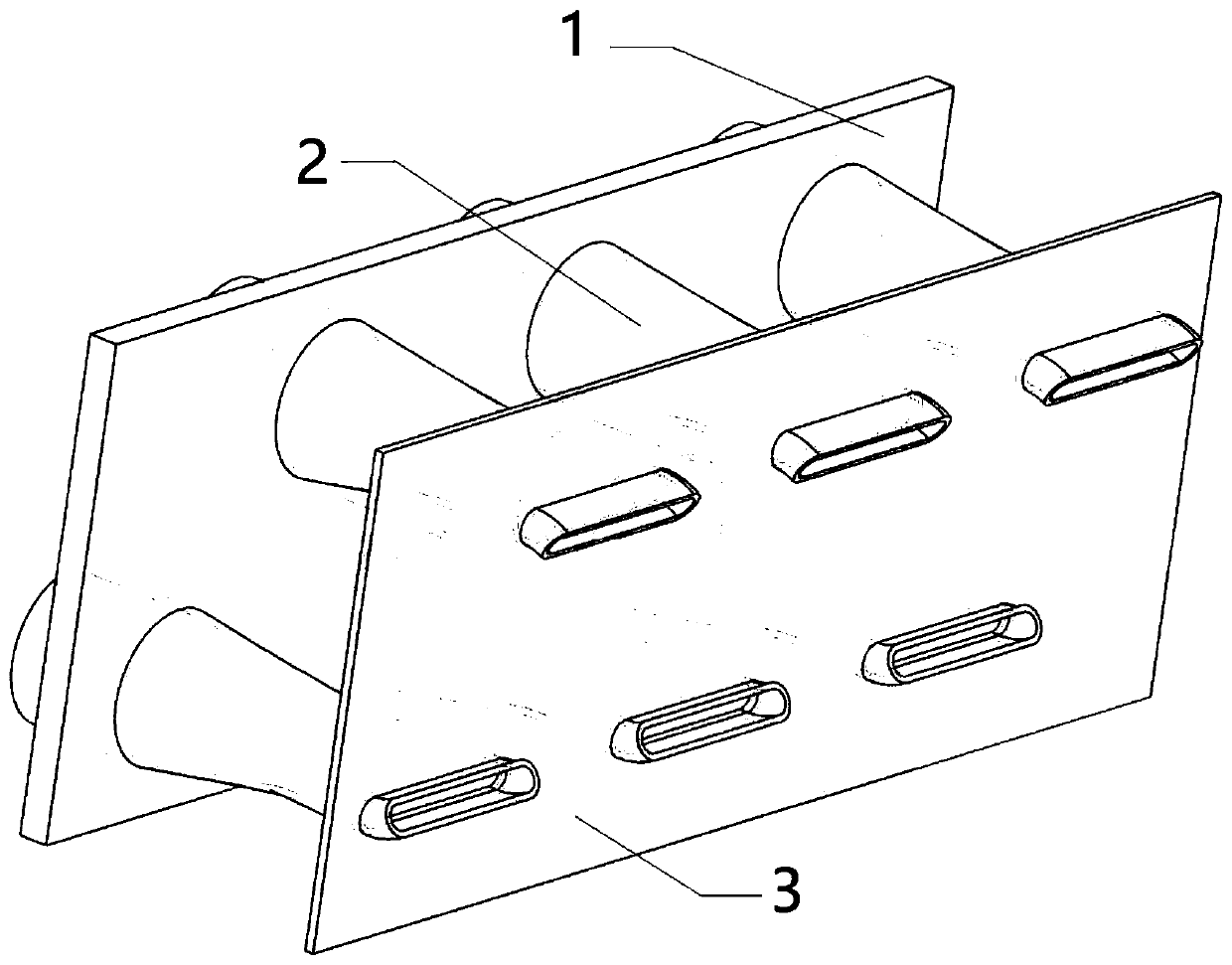

[0084] Taking the plate 6 with a specification of 16mm×2000mm×8000mm as an example, 2000mm is the width of the plate, and a group of cooling center lines must be completely covered. A seamless steel pipe with an inner diameter of 46mm, an outer diameter of 50mm, and a wall thickness of 2mm is selected. The jet pipe 2 is processed by a pipe bender, the original pipe diameter section 7 is connected to the external pipeline, the variable section section is 100mm, the outlet shape is racetrack, and the two ends are semicircular 30mm long, 3mm flat fixed end. Use the pipe bending machine to process the curved jet nozzle. The process requires the incident water flow to impact the surface of the cooling steel plate at 60°. The vertical direction of the water outlet of the jet nozzle is 1m high from the cooling plate, and the horizontal direction that can be calculated is 0.577m. The water outlet is 30mm long, and 67 jet tubes are required to completely cover the 2000mm plate width...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com