A special mold for small catheter tip machine

The technology of a pointed machine and a small catheter is applied in the field of advanced small catheter processing equipment, which can solve the problems of long processing time, low processing efficiency, hidden dangers of production accidents, etc., and achieve the effects of good finished product quality, high processing efficiency and good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0027] Specific embodiments of the invention will be described in detail below.

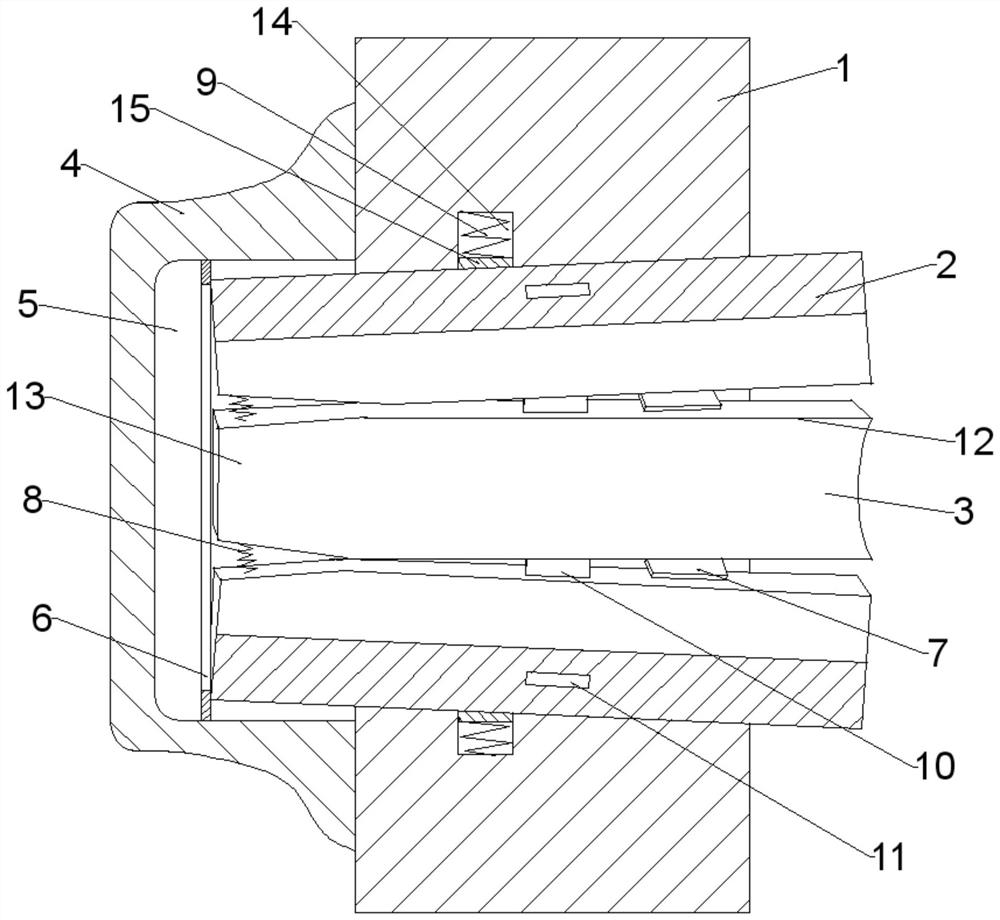

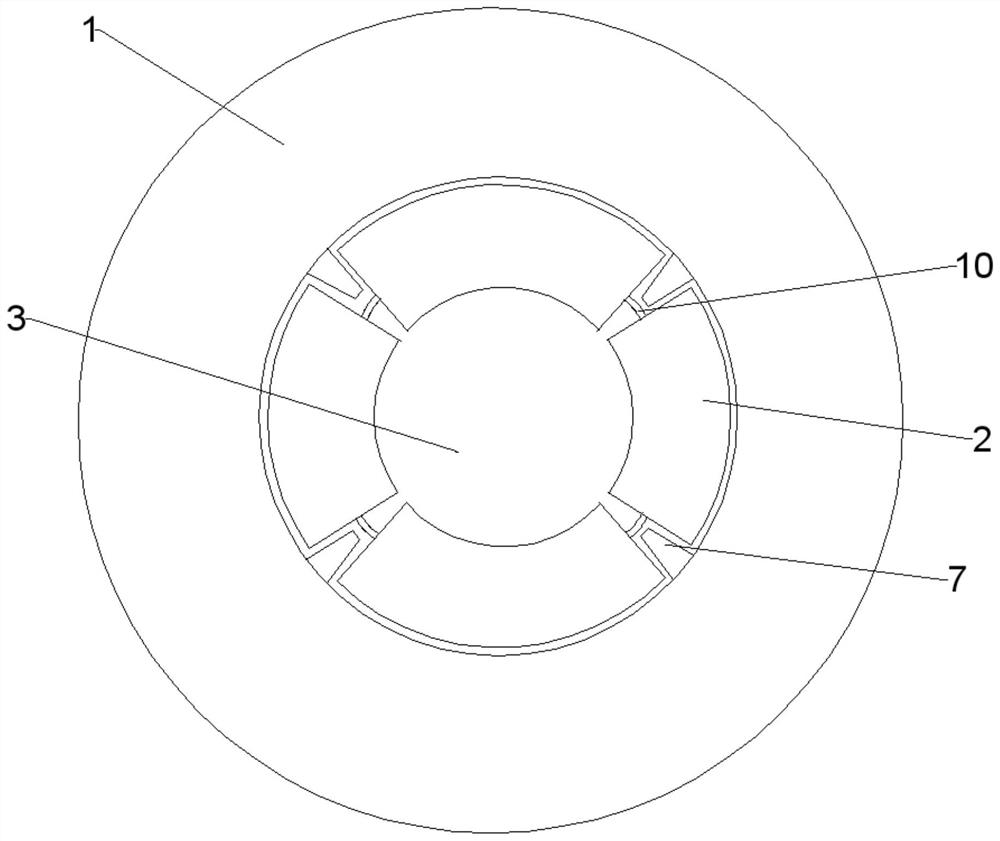

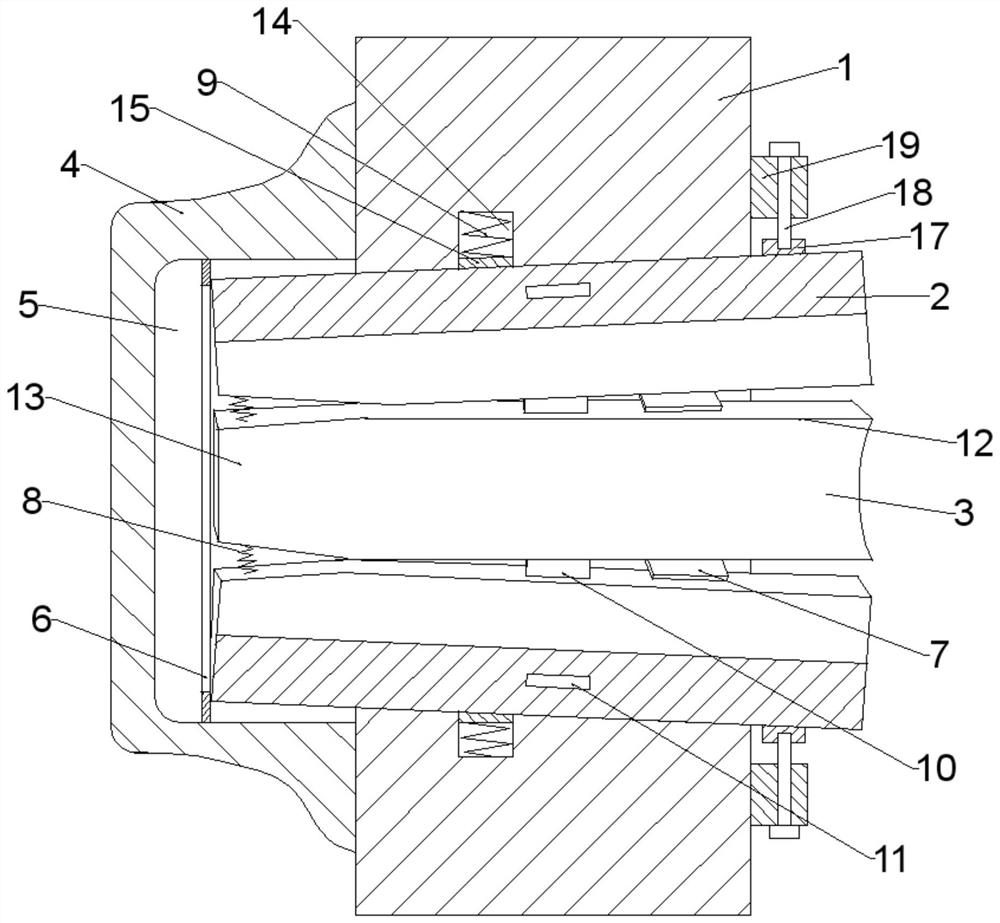

[0028] A special mold for a small catheter tip machine, such as Figures 1 to 4 As shown, it includes a base 1 and a molding die in the base; the molding die is composed of several petal mold bodies 2, forming a molding cavity 3 with a tapered structure inside the molding die; in order to ensure the stability of the overall structure of the mold, the mold The distance between the maximum gap between the body and the inner wall of the base mounting hole is 2-5mm. Such a structural arrangement can ensure the stability of the mold to the greatest extent during the pointed head processing, so that the distance between the mold bodies is not too large and avoids large gaps. Abnormal fluctuations in amplitude.

[0029] The rear end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com