Fuel heater of engine

A fuel heater and engine technology, applied to water heaters, fluid heaters, engine components, etc., can solve problems such as difficulty in starting diesel engines in winter, freezing and flameout of diesel pipelines, etc. Easy to use effect with operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

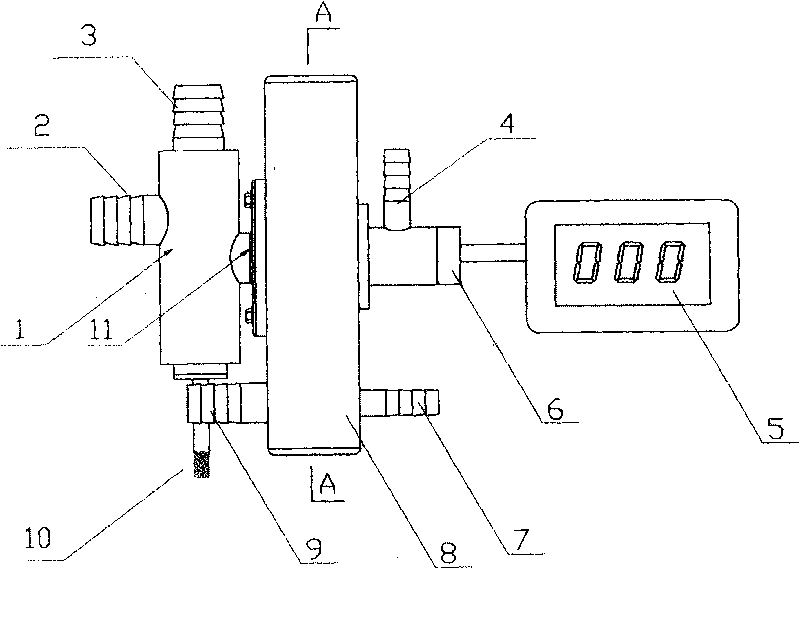

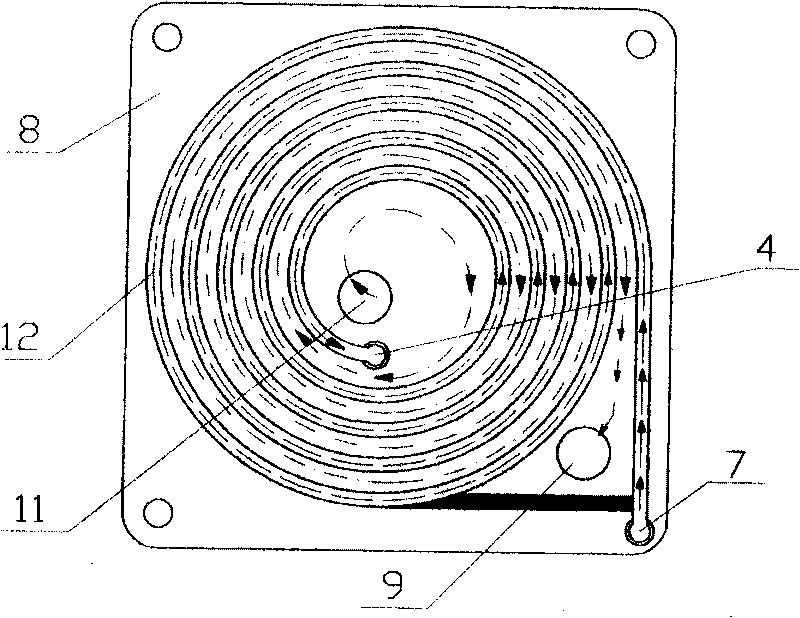

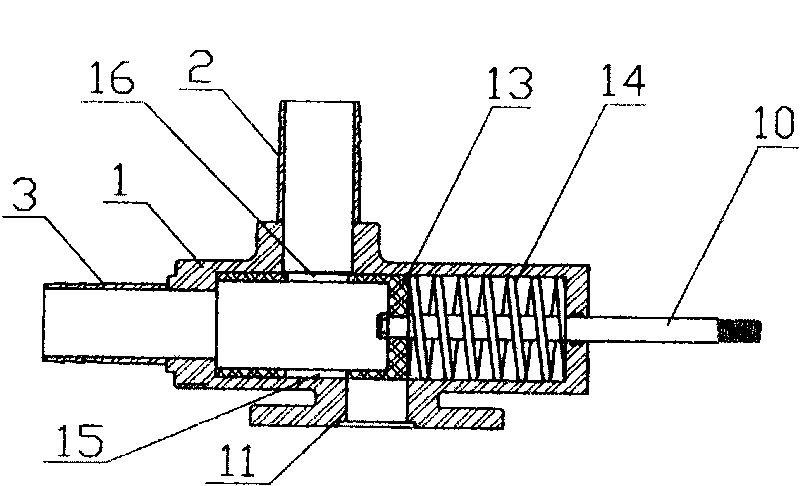

[0011] The best embodiments of the invention will be described in detail below in conjunction with the accompanying drawings. An engine fuel heater, in which a water inlet pipe 11 is installed between the three-way regulating valve body 1 and the fuel heater casing 8, and the water inlet pipe 11 communicates the three-way regulating valve body 1 and the fuel heater casing 8 with each other; The engine hot water straight discharge pipe 2 and the engine hot water input pipe 3 are installed on the three-way regulating valve body 1, and the engine hot water straight discharge pipe 2 and the water inlet pipe 11 are misaligned in the axial direction of the three-way regulating valve body 1. The spool 13 with the drain hole 16 and the water inlet hole 15 is fitted in the cavity of the three-way regulating valve body 1 in an axially movable manner, and the water inlet hole 15 and the drain hole 16 are connected with the water inlet pipe 11 and the engine hot water straight discharge pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com