Pipe fitting

A technology for pipe fittings and pipe bodies, which is applied in the field of connectors, can solve the problems of large margin, insufficient sealing, and difficult to disassemble, and achieves the effect of solving blocked pipes, not easy to loosen, and easy to maintain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

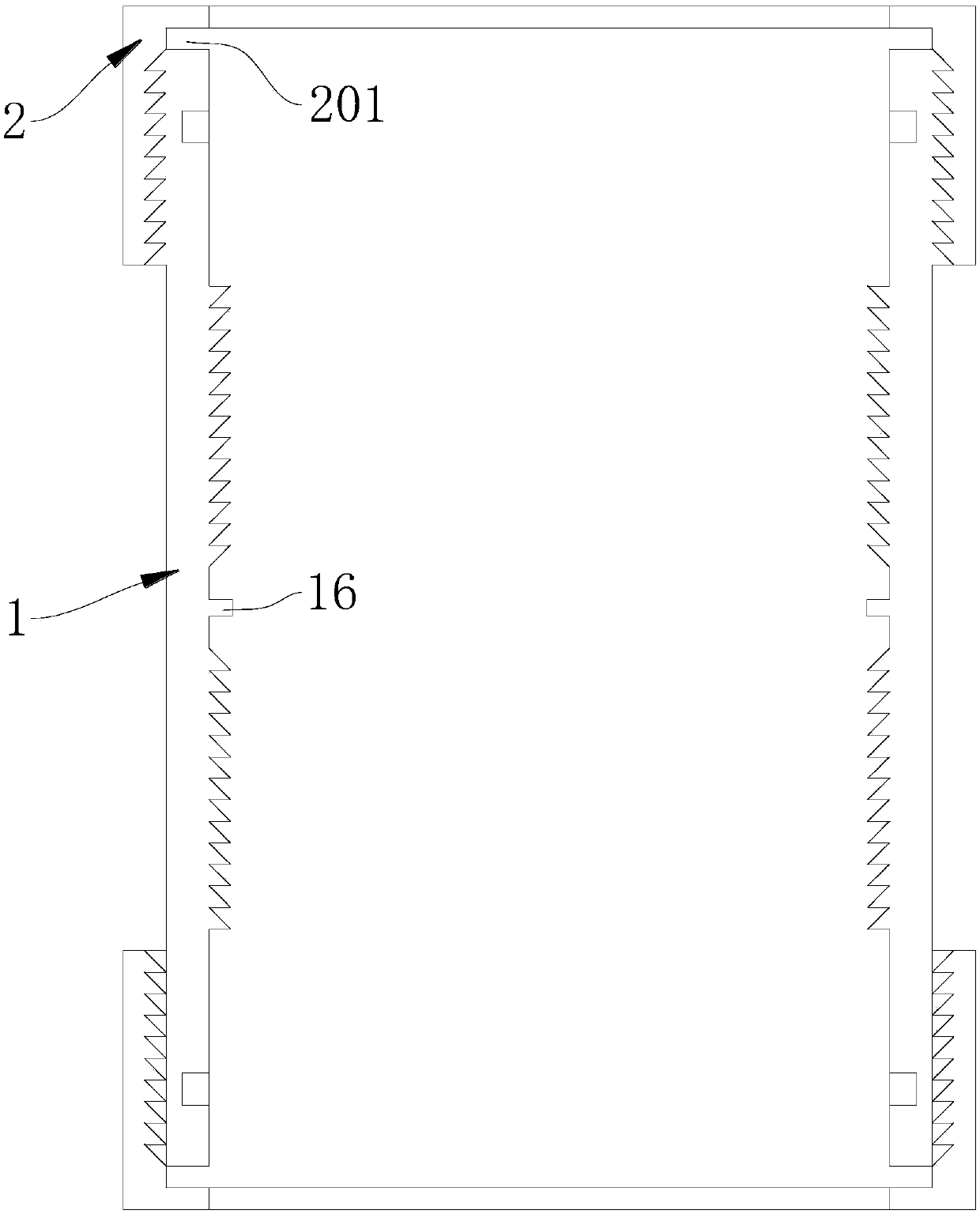

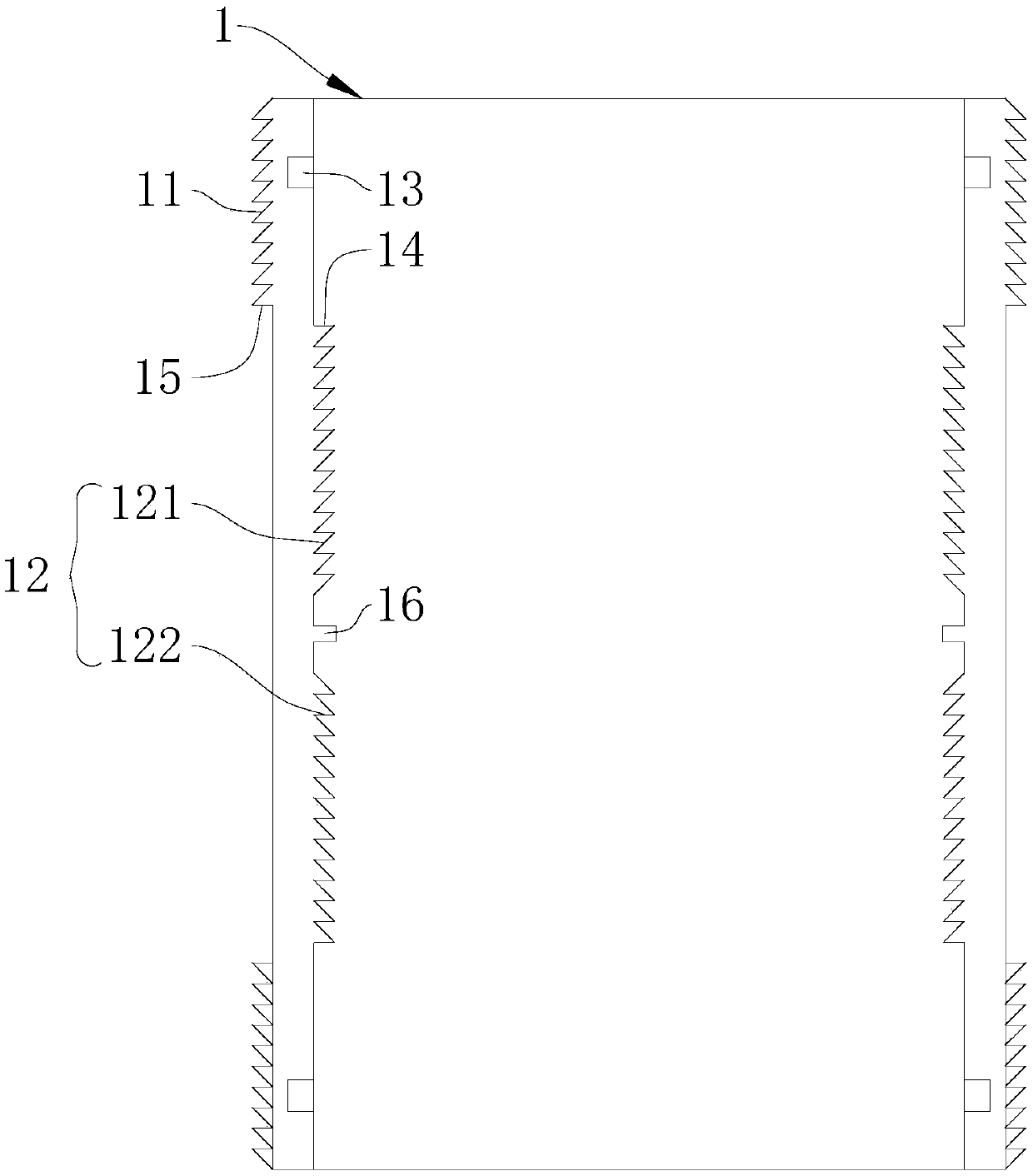

[0029] Figure 1-4 Shown is the pipe fitting of the first embodiment of the present invention, the pipe fitting is strip-shaped, and the pipe fitting includes a pipe body 1, a seal 3 and a nut 2, the outer wall of the pipe body 1 is provided with an external thread 11, and the inner wall of the pipe body 1 is provided with The first internal thread 12, the first internal thread 12 is used to connect the pipeline, the nut 2 is provided with the second internal thread 21, the external thread 11 is threadedly matched with the second internal thread 21, and makes the sealing member 3 compress the outer wall of the pipeline, Thus, the gap between the inner wall of the pipe body 1 and the outer wall of the pipeline is sealed. In the present invention, the first internal thread 12 is provided on the inner wall of the pipe body 1, and the first internal thread 12 is detachably threaded with the pipeline, thereby facilitating the connection of the pipe fitting to the pipeline and the r...

no. 2 example

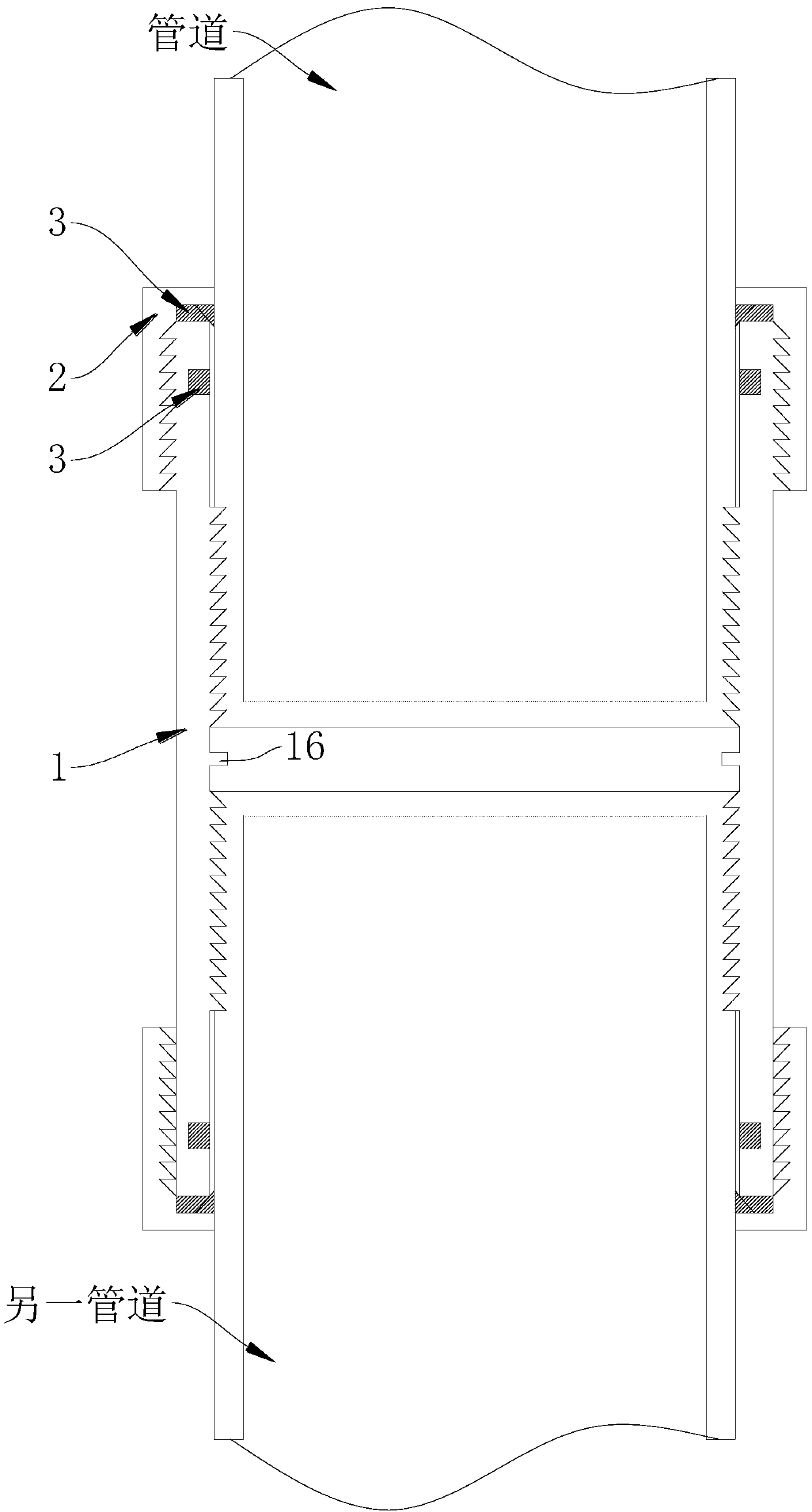

[0039] Figure 5 The pipe fitting of the second embodiment of the present invention is shown. The pipe fitting is in the shape of a strip. The pipe fitting includes a pipe body 1, a seal 3 and a nut 2. The outer wall of the pipe body 1 is provided with an external thread 11, and the inner wall of the pipe body 1 is provided with The first internal thread 12, the first internal thread 12 is used to connect the pipeline, the nut 2 is provided with the second internal thread 21, the external thread 11 is threadedly matched with the second internal thread 21, and makes the sealing member 3 compress the outer wall of the pipeline, Thus, the gap between the inner wall of the pipe body 1 and the outer wall of the pipeline is sealed. In the present invention, the first internal thread 12 is provided on the inner wall of the pipe body 1, and the first internal thread 12 is detachably threaded with the pipeline, thereby facilitating the connection of the pipe fitting to the pipeline and...

no. 3 example

[0046] Image 6 and Figure 7 The pipe fitting of the third embodiment of the present invention is shown. The third embodiment provides the pipe fitting of the first embodiment, which is different from the first embodiment in that the pipe fitting is in the shape of an elbow. It can be understood that the pipe fitting can also be in other shapes , its shape is not limited, and its shape does not affect the characteristics of the pipe fittings in the present invention, which are easy to install and disassemble, and have reliable sealing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com