A mechanically enhanced composite tissue engineering scaffold material and its preparation method

A technology of composite tissue and scaffold materials, applied in the field of biomedical materials, can solve the problems of too fast degradation, long degradation cycle, unfavorable seed cell adhesion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

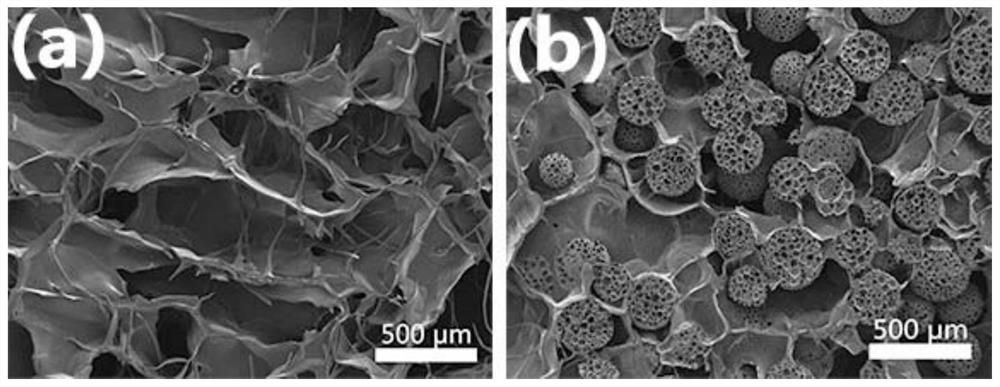

[0054] Embodiment 1, the preparation of composite support material

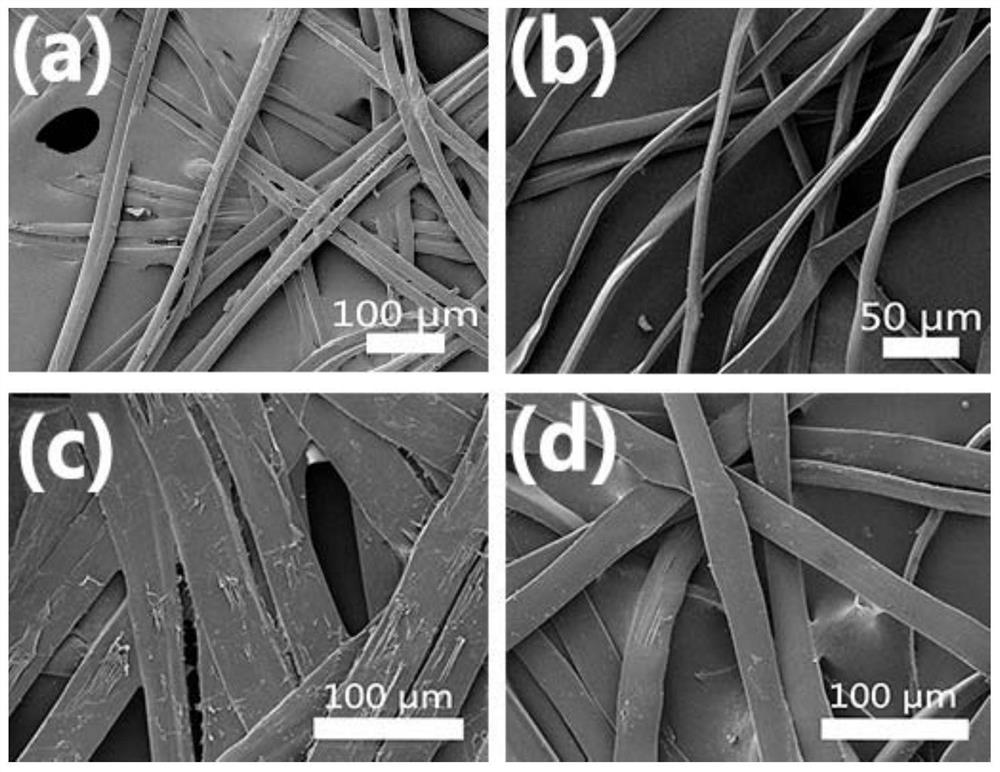

[0055] (1) Evenly stretch the degummed mulberry silk into a mesh structure, cut it into a silk mesh with a length of 7cm, a width of 4cm, and a thickness of 0.5cm, with a mass of 30mg, and spread the silk mesh into a mold of 7cm×4cm×1cm Inside.

[0056] (2) 9 g of gelatin was dissolved in deionized water so that the concentration of the gelatin solution was 30%. 0 mg polylactic acid porous microspheres, 2.25 mL of silk fibroin protein solution with a concentration of 20 mg / mL and 1.5 mL of 30% gelatin solution were blended, and the volume of the resulting suspension was 15 mL, so that the concentration of porous microspheres was 0 mg / mL. The protein concentration is 3mg / mL, the gelatin concentration is 3wt%, and the gelatin mass in the suspension is 450mg.

[0057] (3) Inject the suspension in step (2) into the mold in step (1), cool and shape at -20°C, and vacuum freeze-dry (the freeze-drying temperature i...

Embodiment 2

[0059] Embodiment 2, the preparation of composite support material

[0060] (1) Evenly stretch the degummed mulberry silk into a mesh structure, cut it into a silk mesh with a length of 7cm, a width of 4cm, and a thickness of 0.5cm, with a mass of 45mg, and spread the silk mesh into a mold of 7cm×4cm×1cm Inside.

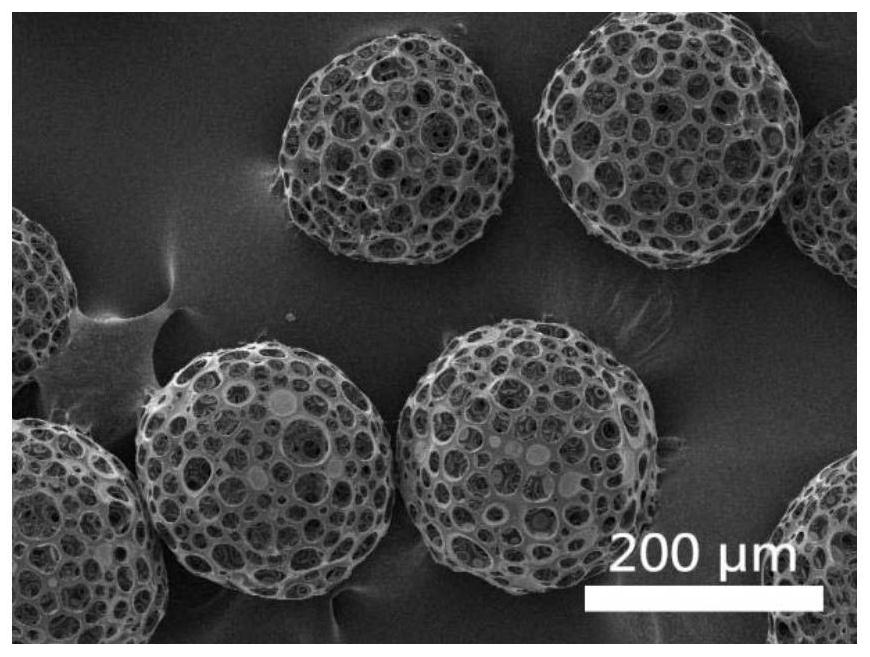

[0061] (2) 9 g of gelatin was dissolved in deionized water so that the concentration of the gelatin solution was 30%. 225mg of polylactic acid porous microspheres and 9mL concentration of 25mg / mL silk fibroin protein solution and 4.5mL30% gelatin solution are blended to obtain 15mL of suspension, so that the concentration of porous microspheres is 15mg / mL, the concentration of silk fibroin protein It is 15mg / mL, the gelatin concentration is 9wt%, and the gelatin quality in the suspension is 1350mg.

[0062] (3) Inject the suspension in step (2) into the mold in step (1), cool and shape at -20°C, and vacuum freeze-dry (the freeze-drying temperature is -55°C) to init...

Embodiment 3

[0064] Embodiment 3, the preparation of composite support material

[0065] (1) Evenly stretch the degummed tussah silk into a mesh structure, cut it into a silk mesh with a length of 7cm, a width of 4cm, and a thickness of 0.5cm, with a mass of 40mg, and spread the silk mesh into a mold of 7cm×4cm×1cm Inside.

[0066] (2) 9 g of gelatin was dissolved in deionized water so that the concentration of the gelatin solution was 30%. 160mg of polylactic acid porous microspheres were blended with 7.5mL of silk fibroin protein solution with a concentration of 20mg / mL and 3.5mL of 30% gelatin solution to obtain a suspension of 15mL, so that the concentration of porous microspheres was 10.67mg / mL. The protein concentration is 10mg / mL, the gelatin concentration is 7wt%, and the mass of gelatin in the suspension is 1050mg.

[0067] (3) Inject the suspension in step (2) into the mold in step (1), cool and shape at -20°C, and vacuum freeze-dry (the freeze-drying temperature is -55°C) to i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap