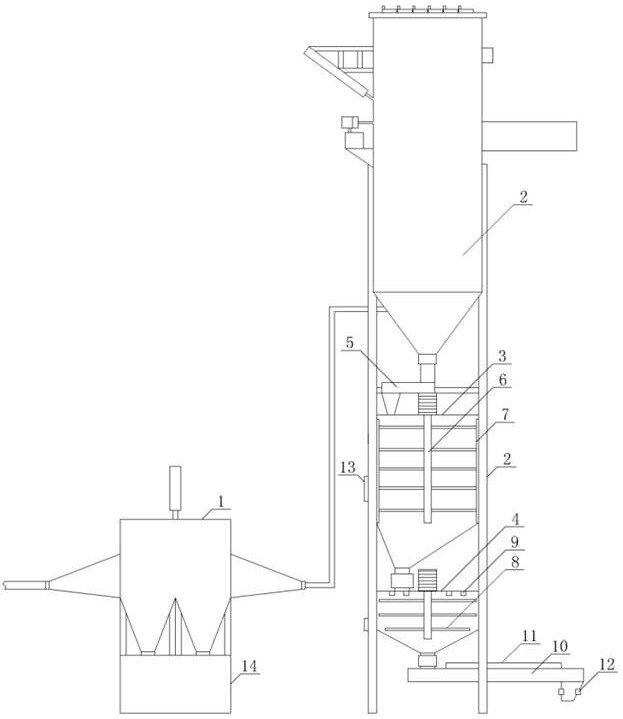

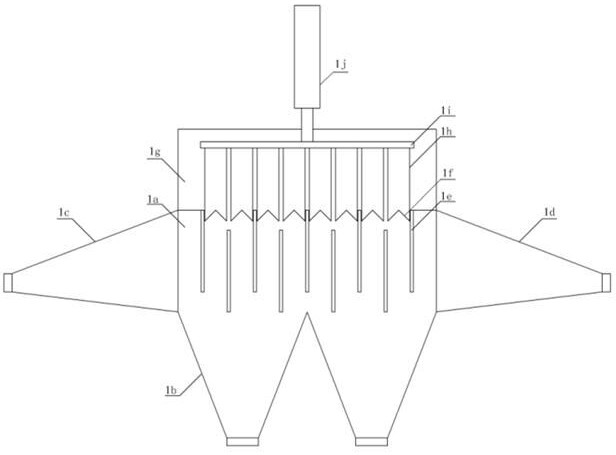

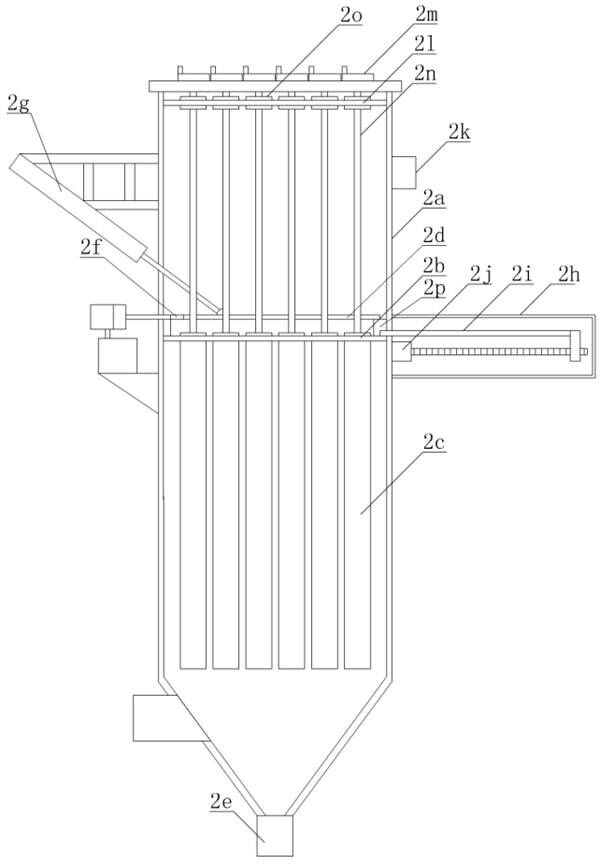

A high-efficiency dust removal system and process for dust

A dust removal system and dust technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as environmental pollution, physical and mental health hazards of operators, and achieve convenient use, avoid secondary dust, and stable structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The process of the high-efficiency dust removal system for dust first collects the dust airflow from each dust-producing area and sends it to the pre-sedimentation device for pre-sedimentation, and separates and collects large particles of dust with a particle size of more than 50 μm from the dust airflow; after pre-sedimentation treatment The final dust airflow is sent to the bag type dust removal device for pulse bag type dust removal, and the clean air is discharged directly; the dust obtained by the pulse bag type dust removal and large particle dust are sent to the ash storage bin for storage at the same time; and then discharged into the discharge bin The dust is sprayed with water mist and stirred continuously for 1 min; then the dust is sprayed with foam before loading into the truck.

Embodiment 2

[0055] The process of the high-efficiency dust removal system for dust first collects the dust airflow from each dust-producing area and sends it to the pre-sedimentation device for pre-sedimentation, and separates and collects large particles of dust with a particle size of more than 50 μm from the dust airflow; after pre-sedimentation treatment The final dust airflow is sent to the bag type dust removal device for pulse bag type dust removal, and the clean air is discharged directly; the dust obtained by the pulse bag type dust removal and large particle dust are sent to the ash storage bin for storage at the same time; and then discharged into the discharge bin The dust is sprayed with water mist and stirred continuously for 30 minutes; and then the dust is sprayed with foam before loading and transporting.

Embodiment 3

[0057] The process of the high-efficiency dust removal system for dust first collects the dust airflow from each dust-producing area and sends it to the pre-sedimentation device for pre-sedimentation, and separates and collects large particles of dust with a particle size of more than 50 μm from the dust airflow; after pre-sedimentation treatment The final dust airflow is sent to the bag type dust removal device for pulse bag type dust removal, and the clean air is discharged directly; the dust obtained by the pulse bag type dust removal and large particle dust are sent to the ash storage bin for storage at the same time; and then discharged into the discharge bin The dust is sprayed with water mist and stirred continuously for 15 minutes; and then the dust is sprayed with foam before loading into the truck.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com