Automatic laser welding machine for electrical connector and multi-conductor cable

A laser welding machine and electrical connector technology, applied in laser welding equipment, welding equipment, welding equipment and other directions, can solve the problems of production efficiency electrical connector popularization resistance, workers' health hazards, low processing efficiency and other problems, to improve production Efficiency and machining accuracy, reducing the number of workers and labor intensity, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0027] see Figure 1 to Figure 6 .

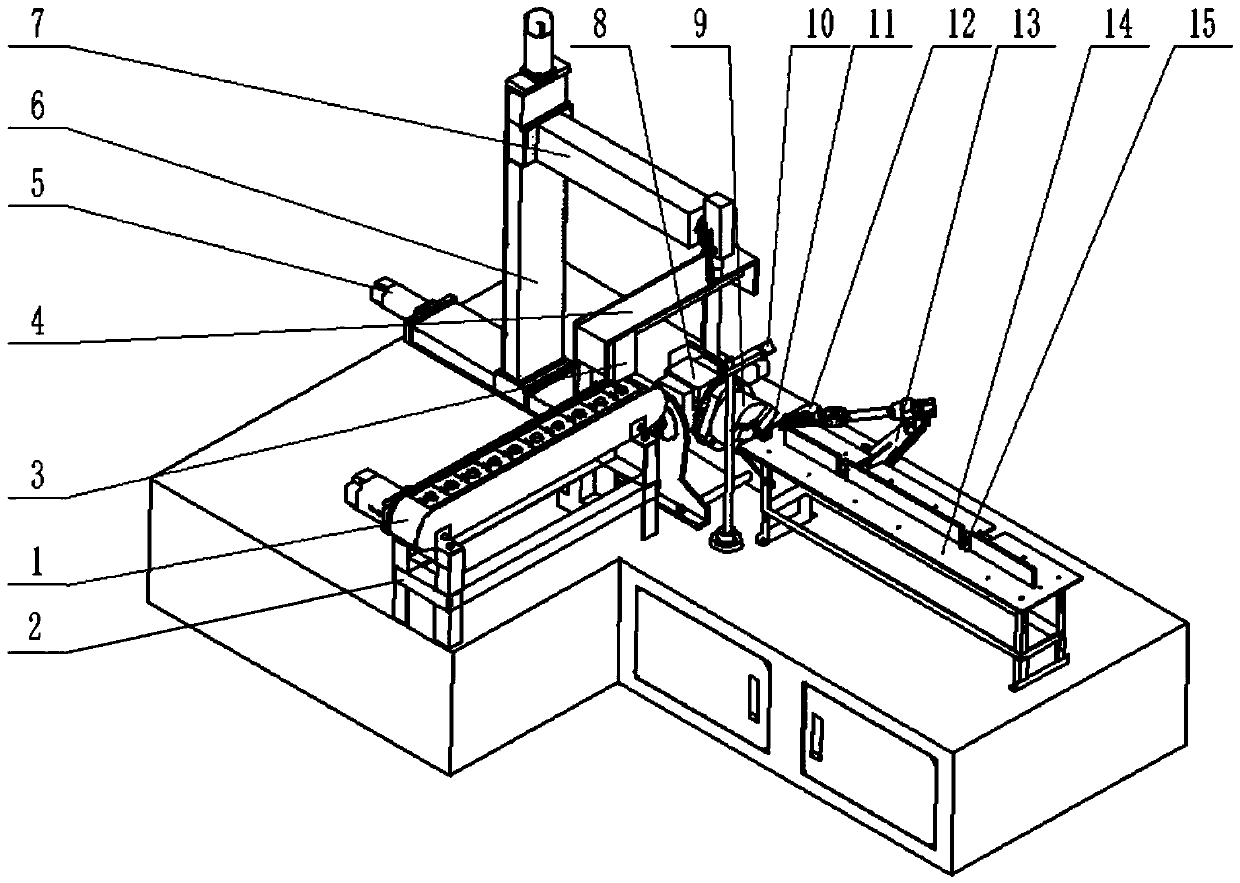

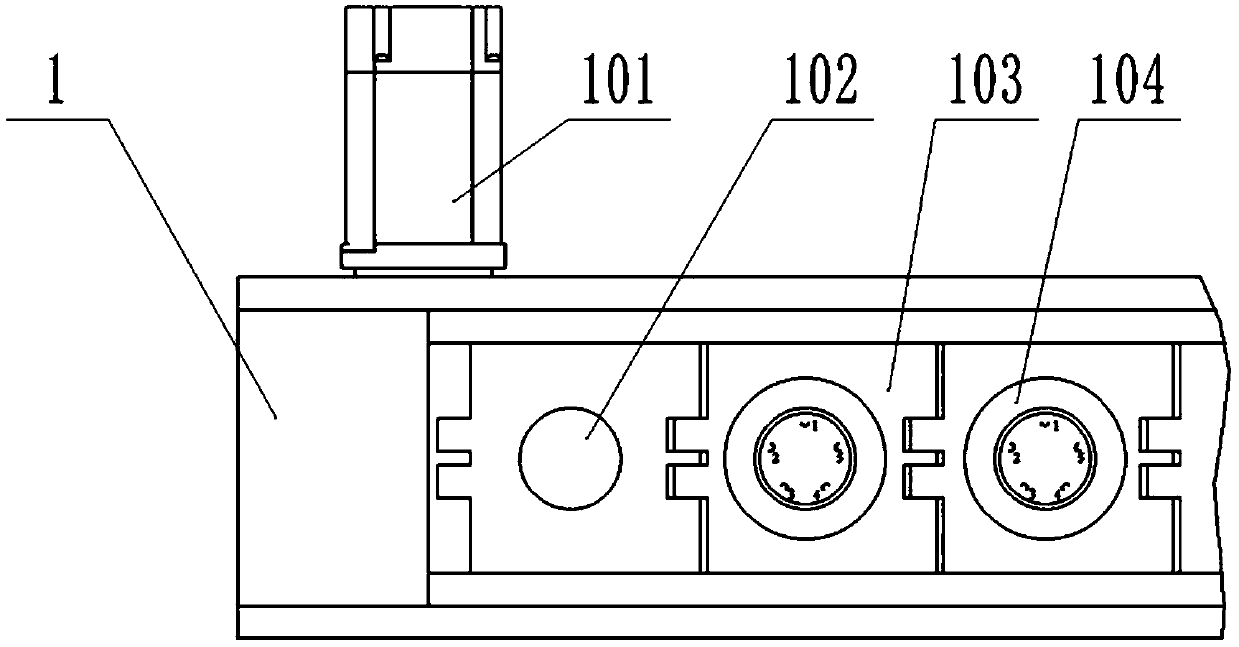

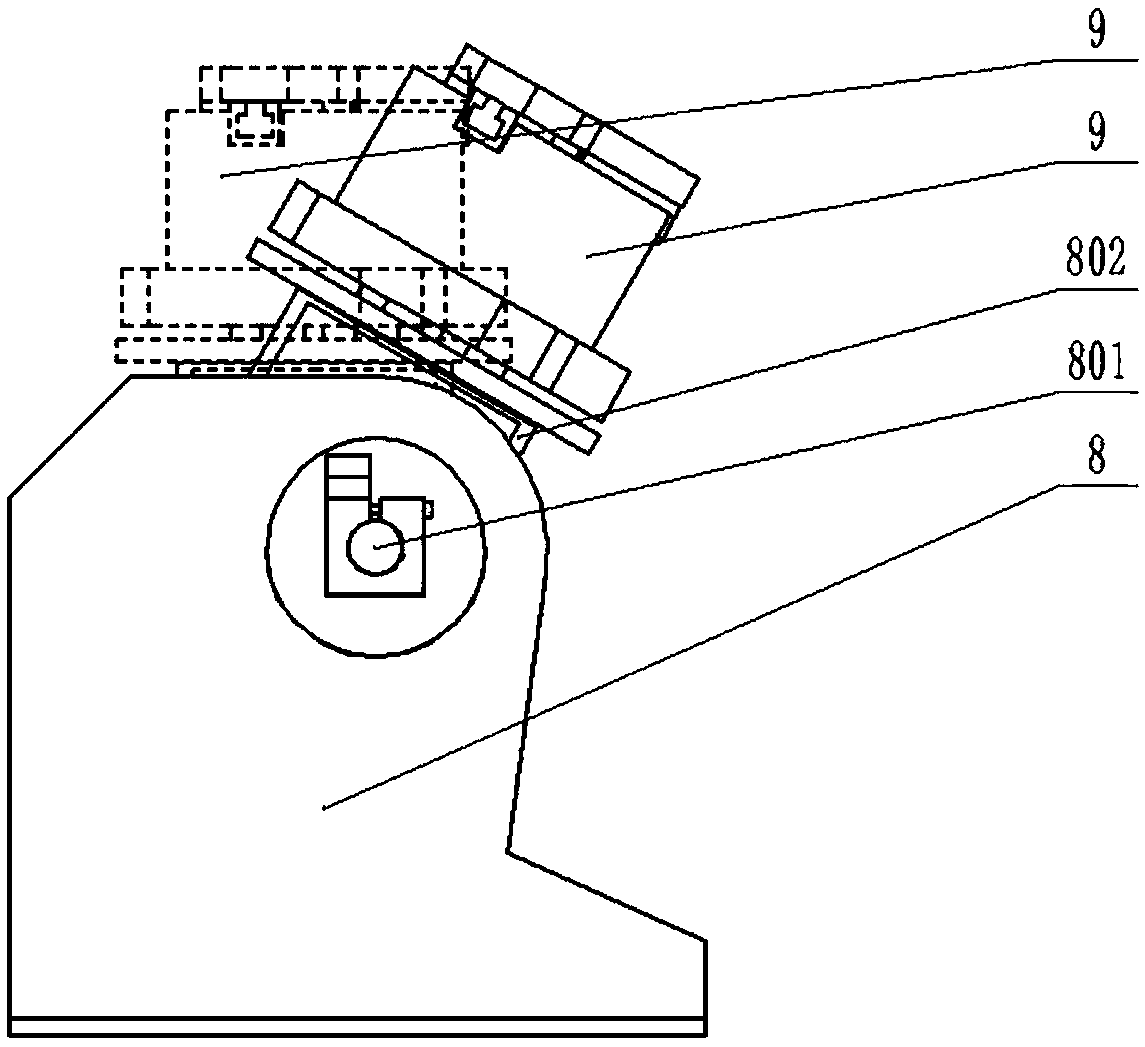

[0028] The present invention is an automatic laser welding machine for electrical connectors and multi-core cables, comprising a crimping platform 14, an electromagnetic chuck 9 arranged at one end of the crimping platform 14, and an electromagnetic chuck 9 arranged at one side of the electromagnetic chuck 9 for transporting the electrical connector. The electrical connector feeding chain plate conveyor belt 1, the laser welding machine 7 arranged above the electromagnetic chuck 9, and the feeding slide for transporting the electrical connector from the electrical connector feeding chain plate conveyor belt 1 to the electromagnetic chuck 9 Cylinder 4, finger cylinder 3 are installed on the material feeding slide cylinder 4, on one side of crimping platform 14, be provided with the clamping manipulator 13 tha...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap