Packaging machine communication control system and control method thereof

A control system and packaging machine technology, applied in packaging automatic control, packaging, packaging protection and other directions, can solve the problems of manual adjustment of input one by one, invisible operation parameters, etc. Real-time visualization, the effect of improving intelligence and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

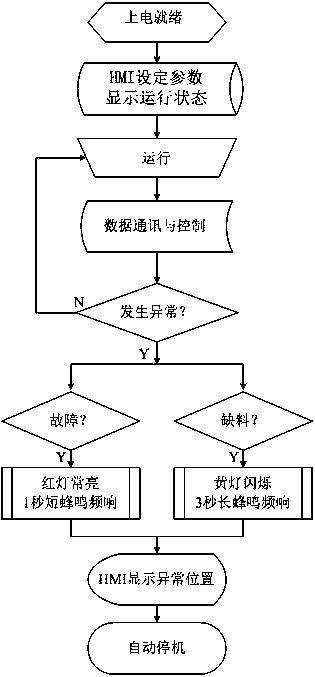

Embodiment Construction

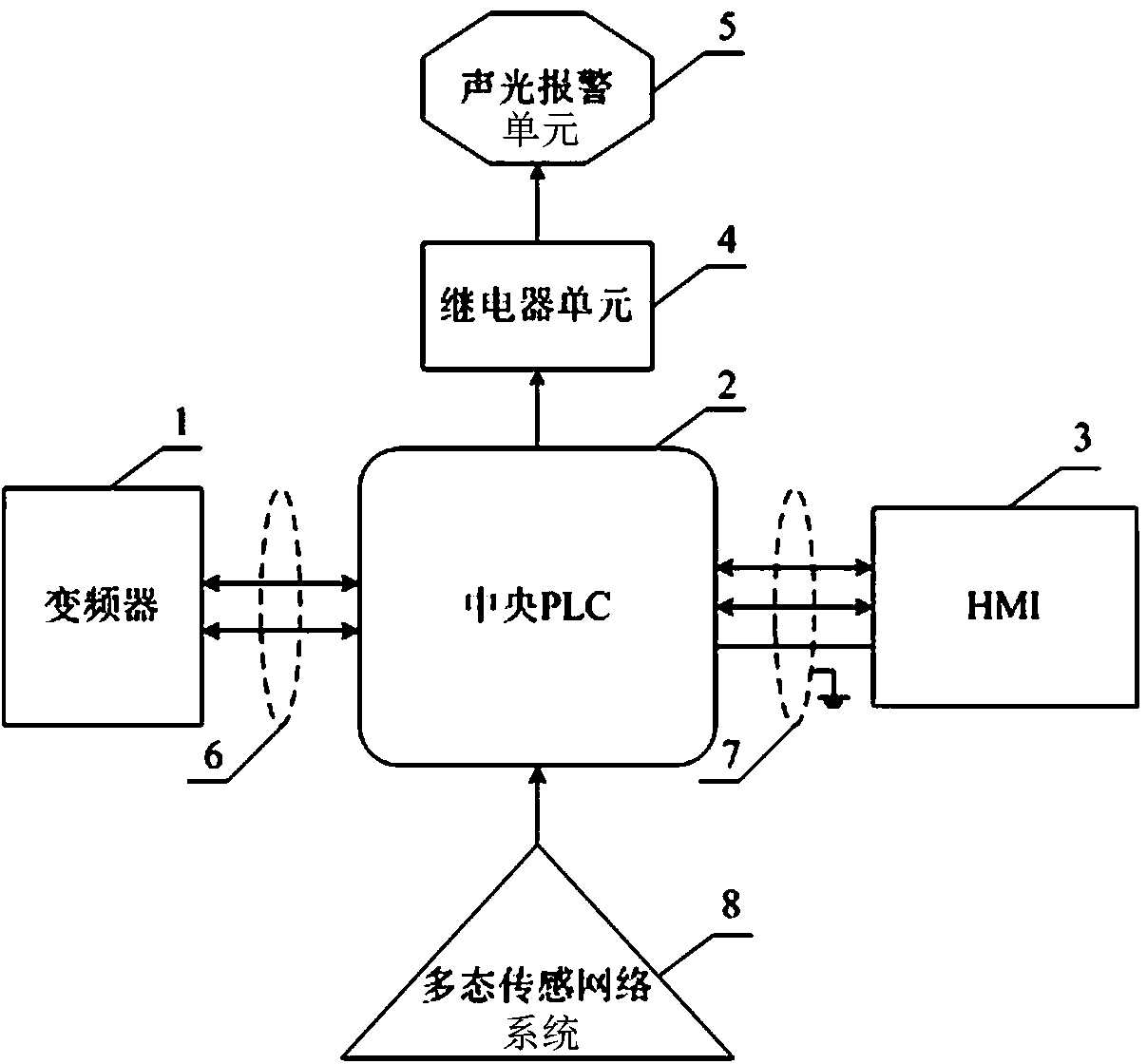

[0030] Specific examples are given below to further describe the technical solution of the present invention in a clear, complete and detailed manner. This embodiment is the best embodiment on the premise of the technical solution of the present invention, but the protection scope of the present invention is not limited to the following embodiments.

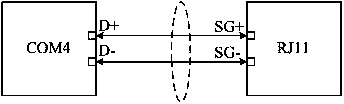

[0031] Packaging machine communication control circuit and control system, including central PLC2, frequency converter 1, HMI3, also includes relay unit 4, sound and light alarm unit 5 and multi-state sensor network system 8, said central PLC2 communicates with the frequency conversion through the first cable 6 The PLC 1 is interconnected and exchanges communication data, and the central PLC2 is interconnected with the HMI3 through the second cable 7 and exchanges communication data;

[0032] The multi-state sensor network system 8 includes a reflective photoelectric sensor, a through-beam photoelectric sensor, an inductive proxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com