Plastic tray molding process and formula

A technology of plastic tray and molding process, applied in the direction of plastic recycling and recycling technology, can solve the problems of low service life of plastic tray, unreasonable production process of plastic tray, unscientific ratio of raw materials, etc., and achieve low cost and good economy. Benefit, simple and convenient processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

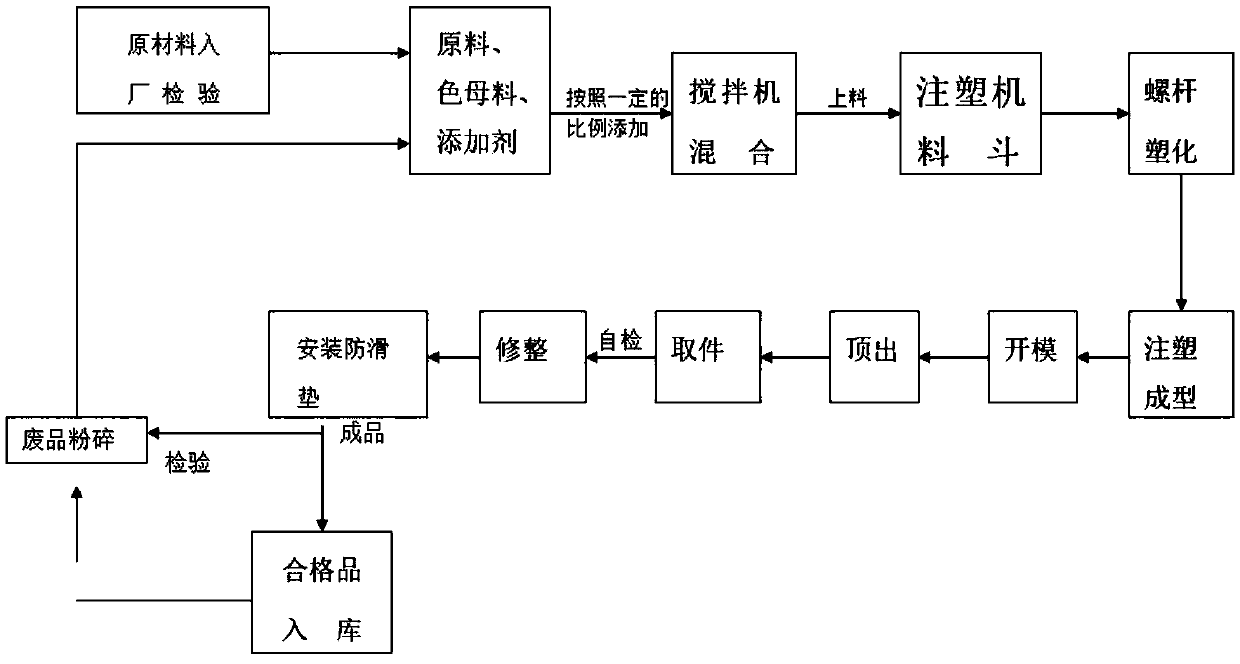

[0019] Such as figure 1 Shown, a kind of plastic tray molding process comprises the following steps:

[0020] Step (1). Material inspection and mixing: Raw materials, color masterbatches, and additives are stored away from light and moisture after entering the factory for inspection. When using, mix raw materials, color masterbatches, and additives according to the mass ratio, and then put them into a mixer to fully stir and mix; raw materials , color masterbatch, additive mass ratio is 75:10:1, the raw materials include polyethylene, polypropylene, polyethylene, polypropylene mass ratio is 45:20;

[0021] Step (2). Injection molding: The mixed material is fully stirred by the mixer and enters the screw of the injection molding machine through the hopper of the injection molding machine, and plasticized for injection molding;

[0022] Step (3). Forming and picking up parts: open the injection mold through the driving mechanism, then eject the mold from the injection mold thro...

Embodiment 3

[0033] Such as figure 1 Shown, a kind of plastic tray molding process comprises the following steps:

[0034] Step (1). Material inspection and mixing: Raw materials, color masterbatches, and additives are stored away from light and moisture after entering the factory for inspection. When using, mix raw materials, color masterbatches, and additives according to the mass ratio, and then put them into a mixer to fully stir and mix; raw materials , color masterbatch, additive mass ratio is 80:15:5, the raw materials include polyethylene, polypropylene, polyethylene, polypropylene mass ratio is 80:40;

[0035] Step (2). Injection molding: The mixed material is fully stirred by the mixer and enters the screw of the injection molding machine through the hopper of the injection molding machine, and plasticized for injection molding;

[0036] Step (3). Forming and picking up parts: open the injection mold through the driving mechanism, then eject the mold from the injection mold thro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com