Bumper paint with silver powder effect and no shielding effect on automobile radar and preparation method

An automotive radar, unshielded technology, applied in coatings and other directions, can solve the problems of radar and bumper chromatic aberration, difficult operation of bumper, poor overall effect, etc., to improve efficiency, save paint, and reduce costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

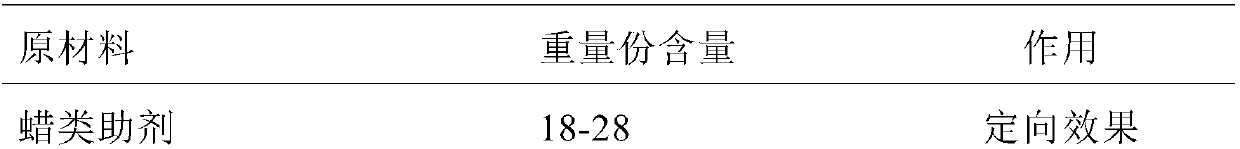

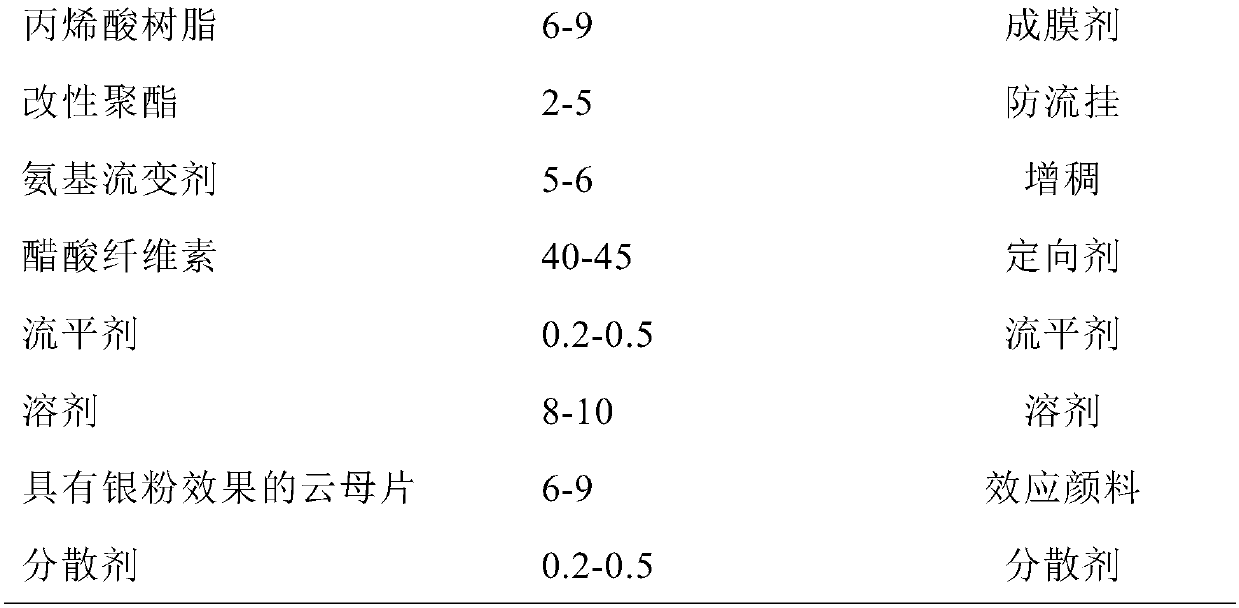

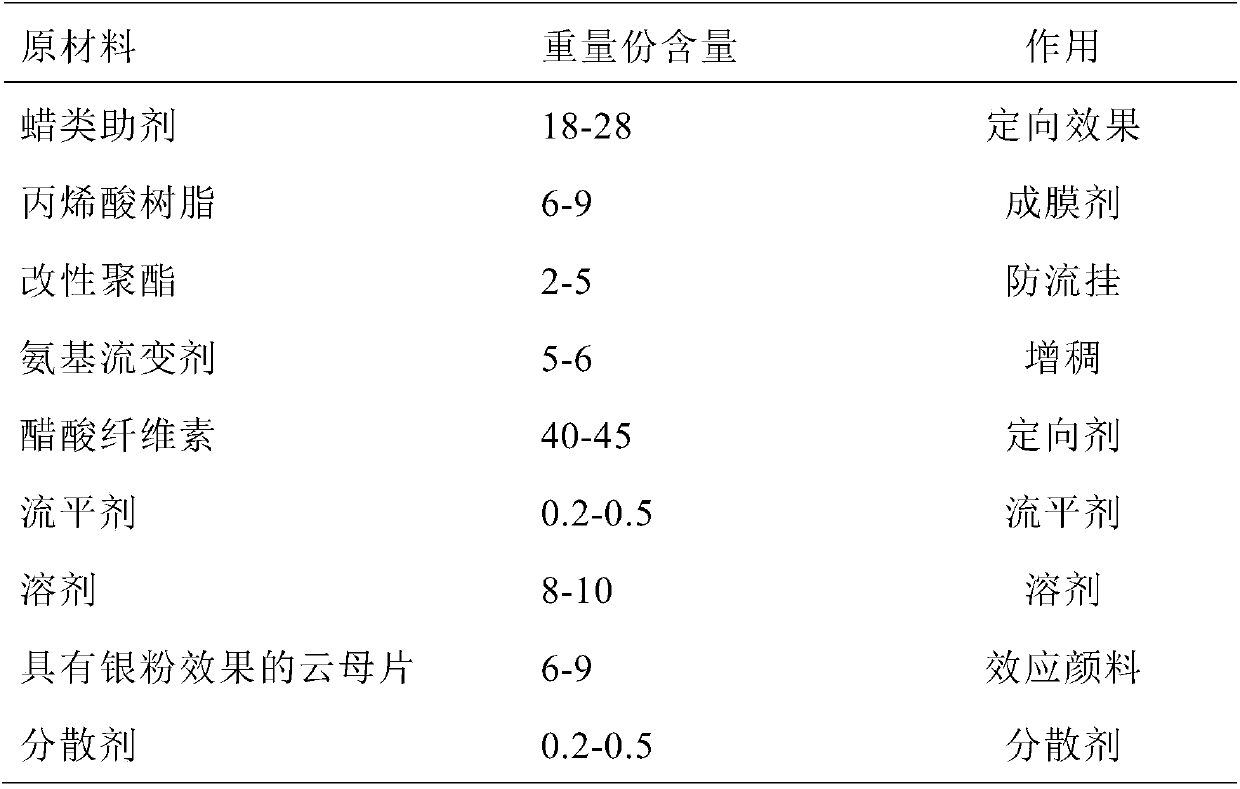

[0027] The preparation method of bumper paint comprises the following steps:

[0028] (1) Preparation of resin mixture: put wax additives, acrylic resin, modified resin, and amino rheological agent into the reactor, stir at 400-600rpm for 25-30min until uniform, then put CAB and leveling agent into the reactor , 600-800rpm speed dispersion for 25-30min, sampling inspection to make the material fineness less than 15um, finally add solvent to adjust the viscosity to 110-130s (T-4 viscosity cup), and obtain the resin mixture after filtration;

[0029] (2) Prepare mica slurry: mix mica flakes with solvent, stir at 400-600rpm for 10-15min, then soak for 8-10hr to obtain mica slurry;

[0030] (3) Preparation of silver paint products: put the prepared resin mixture into a reaction kettle, add a dispersing aid, stir at a speed of 400-600rpm for 10-15min, then maintain a low shear speed, and add mica slurry to the above-mentioned In the mixed liquid, disperse for 25-30min under stirri...

Embodiment 1

[0033] Preparation of resin mixture A: Take a reaction tank, weigh 23kg of wax additives, 8kg of acrylic resin, 3kg of modified resin, and 5kg of amino rheological agent in sequence with an electronic scale, and disperse at 400-600rpm for 25-30 minutes, then add CAB Put 531-125kg, CAB 381-0.5 20kg, and leveling agent 0.5kg into the reaction tank, disperse for 25-30 minutes at a speed of 600-800rpm, check that the fineness is less than 15μm, add butyl acetate solvent to adjust the viscosity, and filter to obtain resin mixture A ;

[0034] Weigh 7kg of Merck Iriodin 9602 mica pigment, 7kg of butyl acetate, disperse at 400-600rpm for 10-15 minutes, then soak for 8-10 hours to obtain silver mica slurry B;

[0035]Add 0.3kg of dispersant Efka FA 4665 to the resin mixture A, and stir evenly; then maintain a low shear speed, and add silver mica slurry B while stirring; clean the B attached in the container with about 1k butyl acetate solvent, Put it into the reaction tank together, ...

Embodiment 2

[0040] Preparation of resin mixture A: Take a reaction tank, weigh 23kg of wax additives, 8kg of acrylic resin, 3kg of modified resin, and 5kg of amino rheological agent in sequence with an electronic scale, and disperse at 400-600rpm for 25-30 minutes, then add CAB Put 531-125kg, CAB 381-2 20kg, and leveling agent 0.5kg into the reaction tank, disperse for 25-30 minutes at a speed of 600-800rpm, check that the fineness is less than 15μm, add butyl acetate solvent to adjust the viscosity, and filter to obtain resin mixture A ;

[0041] Weigh 7kg of Merck Iriodin 9612 mica pigment, 7kg of butyl acetate, disperse at 400-600rpm for 10-15 minutes, then soak for 8-10 hours to obtain silver mica slurry B;

[0042] Add 0.3kg of dispersant Efka FA 4665 to the resin mixture A, and stir evenly; then maintain a low shear speed, and add silver mica slurry B while stirring; clean the B attached in the container with about 1k butyl acetate solvent, Put it into the reaction tank together, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com