Automobile vanadium-titanium-containing steel alloying smelting method

A smelting method and a steel alloy technology are applied in the alloy smelting field of vanadium-containing titanium steel for automobiles, which can solve the problem of high production cost of vanadium-containing titanium steel, and achieve the effects of saving smelting cost, reducing cost and improving strong plasticity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

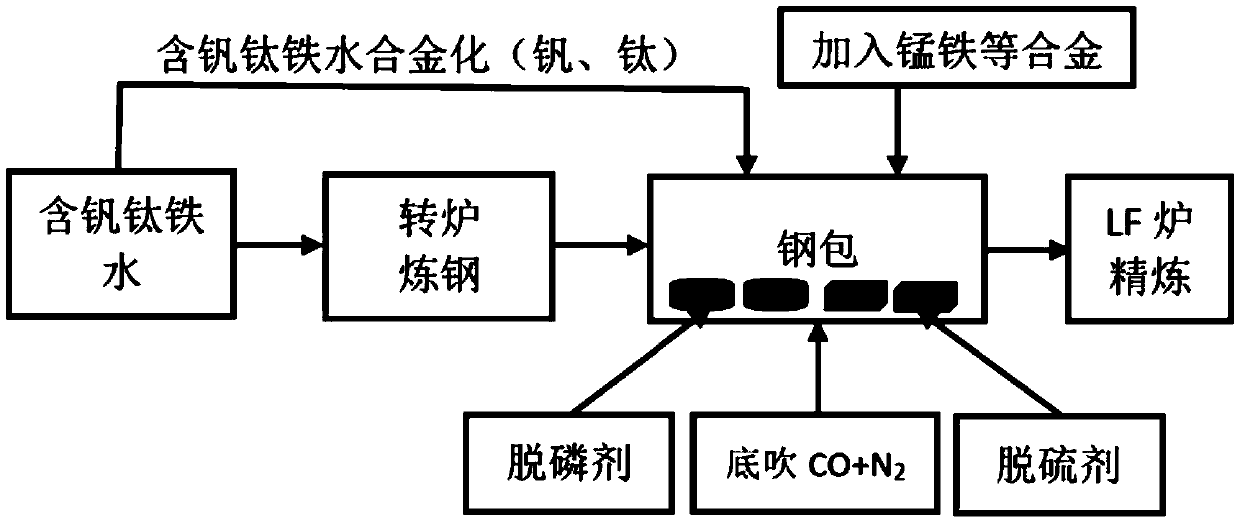

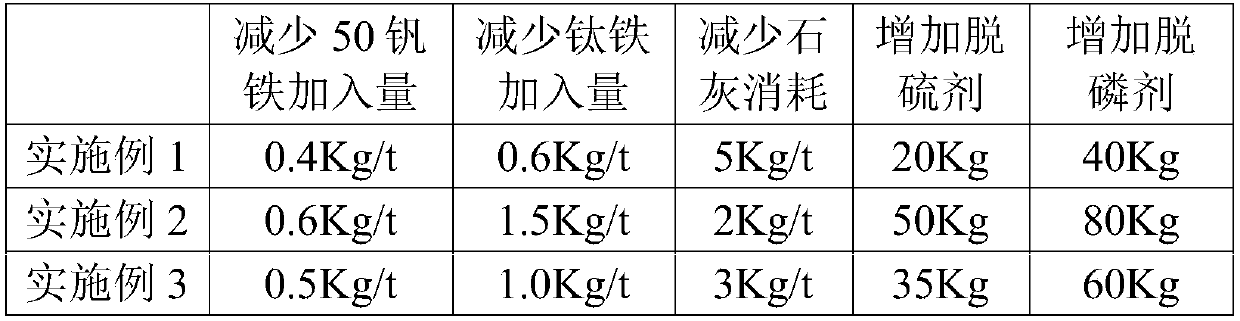

[0036] Reference attachment figure 1 In the flowchart, an embodiment of the present invention provides a method for alloying and smelting vanadium-containing titanium steel for automobiles, including the following steps:

[0037] Step a. Place a 20kg bag of desulfurizer and 40kg bag of dephosphorizer on the bottom of the empty ladle;

[0038] Step b. Pour 13 tons of vanadium-containing titanium molten iron into a ladle containing a desulfurizing agent and a dephosphorizing agent, and transport it to the tapping port of the converter for standby; wherein the weight percentage of the chemical composition of the vanadium-containing titanium molten iron is as follows: C: 4.0%, V: 0.22%, Ti: 0.15%, P: 0.05%, S: 0.04%, the rest is iron and inevitable impurities, the temperature is 1310°C;

[0039] Step c. Continue smelting the remaining vanadium-containing titanium molten iron through the converter without considering the effect of vanadium extraction. Control the weight percentage of the ...

Embodiment 2

[0043] Reference attachment figure 1 In the flowchart, an embodiment of the present invention provides a method for alloying and smelting vanadium-containing titanium steel for automobiles, including the following steps:

[0044] Step a. Place a 50kg bag of desulfurization agent and an 80kg bag of dephosphorization agent on the bottom of the empty ladle;

[0045] Step b. Pour 17 tons of vanadium-containing titanium molten iron into a ladle containing a desulfurizing agent and a dephosphorizing agent, and transport it to the tap hole of the converter for standby; wherein the weight percentage of the chemical composition of the vanadium-containing titanium molten iron is as follows C: 4.6%, V : 0.30%, Ti: 0.3%, P: 0.068%, S: 0.057%, the rest is iron and inevitable impurities, the temperature is 1390℃;

[0046] Step c. Continue smelting the remaining vanadium-containing titanium molten iron through the converter without considering the effect of vanadium extraction. Control the weight p...

Embodiment 3

[0050] Reference attachment figure 1 In the flowchart, an embodiment of the present invention provides a method for alloying and smelting vanadium-containing titanium steel for automobiles, including the following steps:

[0051] Step a. Place 35kg bag of desulfurizer and 60kg bag of dephosphorizer on the bottom of the empty ladle;

[0052] Step b. Pour 15 tons of vanadium-containing titanium molten iron into a ladle containing a desulfurizing agent and a dephosphorizing agent, and transport it to the tap hole of the converter for standby; wherein, the weight percentage of the chemical composition of the vanadium-containing titanium molten iron is as follows C: 4.3%, V : 0.26%, Ti: 0.22%, P: 0.06%, S: 0.05%, the rest is iron and inevitable impurities, the temperature is 1350℃;

[0053] Step c. Continue smelting the remaining vanadium-containing titanium molten iron through the converter without considering the effect of vanadium extraction. Control the weight percentage of the chemic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com