Warm-keeping fabric

A fabric and fiber technology, applied in viscose-made rayon, textiles, papermaking, weft knitting, etc., can solve the problems of easy compaction, thick fabric, poor heat retention, air permeability and antibacterial properties, etc. The effect of improving immunity, good thermal insulation performance, excellent antibacterial and breathable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] A thermal fabric, comprising an upper fabric, a middle fabric, and a bottom fabric arranged sequentially from top to bottom and fixed by a weft-knitted composite structure. The upper fabric is woven from raw materials composed of the following parts by weight:

[0059] Seaweed carbon fiber 40 parts;

[0060] 10 parts cashmere fiber;

[0061] Yak wool fiber 10 parts.

[0062] The middle layer fabric comprises the following components by weight:

[0063] 25 parts of cotton fiber;

[0064] Polyimide fiber 20 parts.

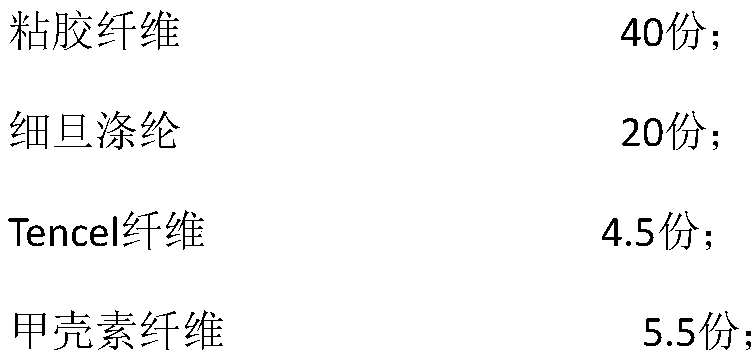

[0065] The bottom fabric comprises the following components by weight:

[0066]

[0067] Viscose fiber is viscose anion fiber, containing 2wt% ceramic powder, ceramic powder is made up of following components by weight: 30 parts of silicon carbide, 20 parts of aluminum oxide, 30 parts of Ti 3 SiC 2 , 1 part of N-(β-aminoethyl)-γ-aminopropyltrimethyl(ethyl)oxysilane, 2 parts of allyl sulfinic acid propyl ester, 0.5 part of sorbitan fatty acid ester.

...

Embodiment 2

[0074] A thermal fabric, comprising an upper fabric, a middle fabric, and a bottom fabric arranged sequentially from top to bottom and fixed by a weft-knitted composite structure. The upper fabric is woven from raw materials composed of the following parts by weight:

[0075] Seaweed carbon fiber 50 parts;

[0076] 15 parts cashmere fiber;

[0077] Yak wool fiber 12 parts.

[0078] The middle layer fabric comprises the following components by weight:

[0079] 27 parts of cotton fiber;

[0080] Polyimide fiber 23 parts.

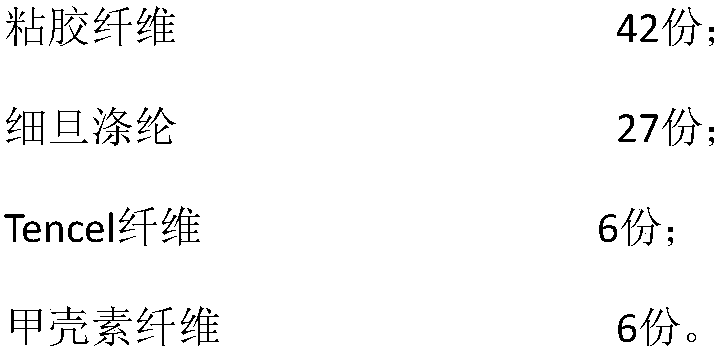

[0081] The bottom fabric comprises the following components by weight:

[0082]

[0083] Viscose fiber is viscose anion fiber, containing 3wt% ceramic powder, ceramic powder is made up of following components by weight: 32 parts of silicon carbide, 24 parts of aluminum oxide, 36 parts of Ti 3 SiC 2 , 2 parts of N-(β-aminoethyl)-γ-aminopropyltrimethyl(ethyl)oxysilane, 3 parts of allyl thiosulfinate propyl ester, 0.6 part of sorbitan fatty acid ester. ...

Embodiment 3

[0090] A thermal fabric, comprising an upper fabric, a middle fabric, and a bottom fabric arranged sequentially from top to bottom and fixed by a weft-knitted composite structure. The upper fabric is woven from raw materials composed of the following parts by weight:

[0091] 60 parts of seaweed carbon fiber;

[0092] 20 parts cashmere fiber;

[0093] 20 parts of yak wool fiber.

[0094] The middle layer fabric comprises the following components by weight:

[0095] 30 parts of cotton fiber;

[0096] 30 parts of polyimide fiber.

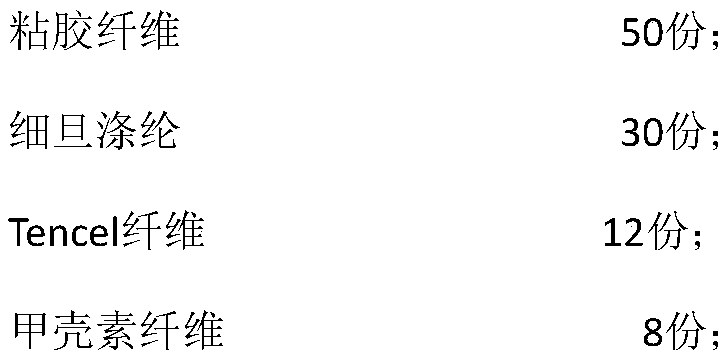

[0097] The bottom fabric comprises the following components by weight:

[0098]

[0099] Viscose fiber is viscose negative ion fiber, containing 4wt% ceramic powder.

[0100] The ceramic powder is composed of the following components by weight: 40 parts of silicon carbide, 30 parts of alumina, 40 parts of Ti 3 SiC 2 ,, 3 parts of N-(β-aminoethyl)-γ-aminopropyltrimethyl(ethyl)oxysilane, 4 parts of allyl thiosulfinate propyl ester, 1 part of s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com