Blade-root bolt fracture fault detection method and medium

A fault detection and bolt technology, which is applied in the fault detection method of blade root bolt fracture and the field of media, can solve the problem of fault failure of blade root bolts and other problems, achieve high accuracy, improve accuracy, and save costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

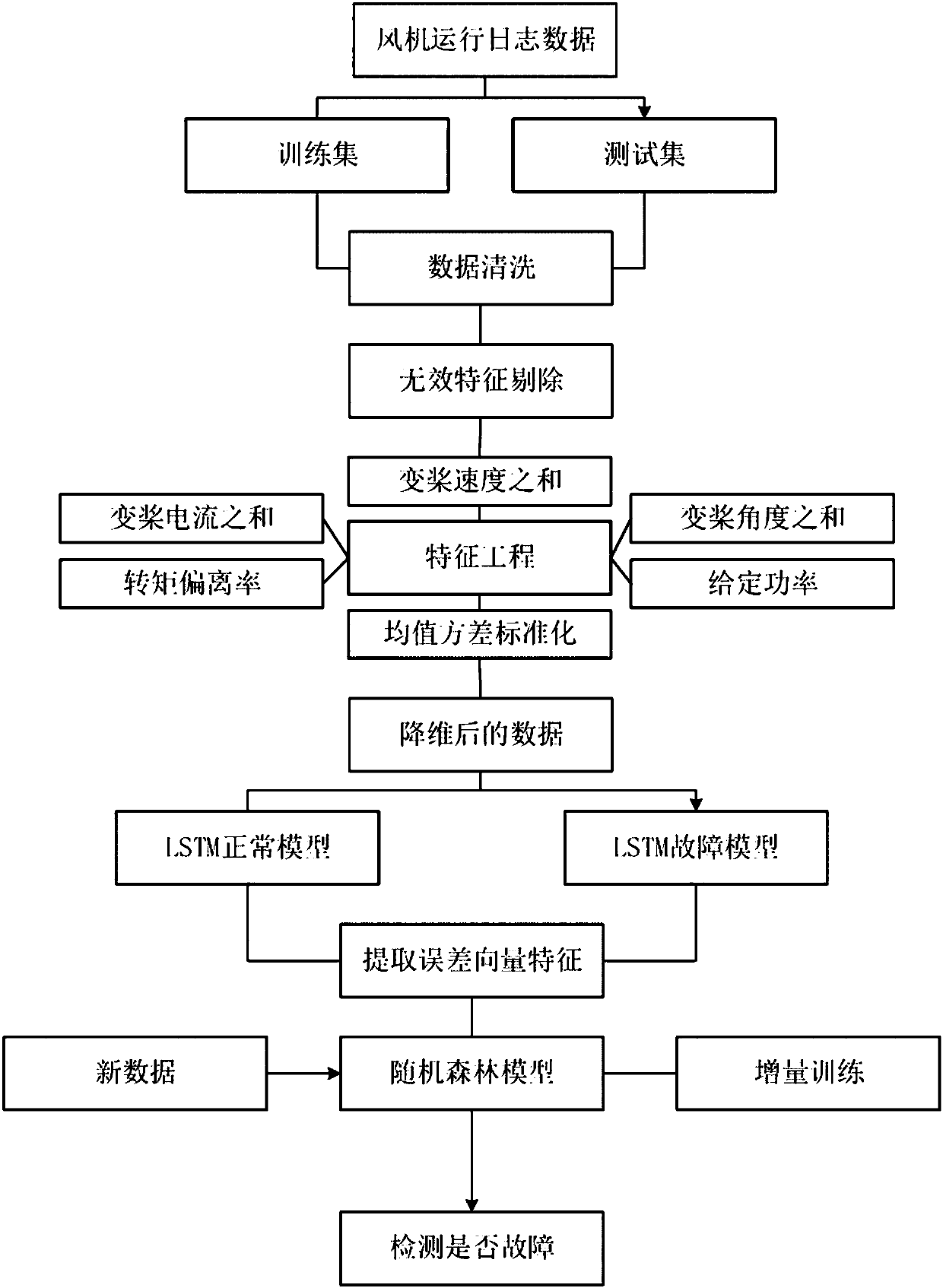

[0035] Such as Figure 1 to Figure 6 As shown, the blade root bolt fracture fault detection method in this embodiment includes the following steps:

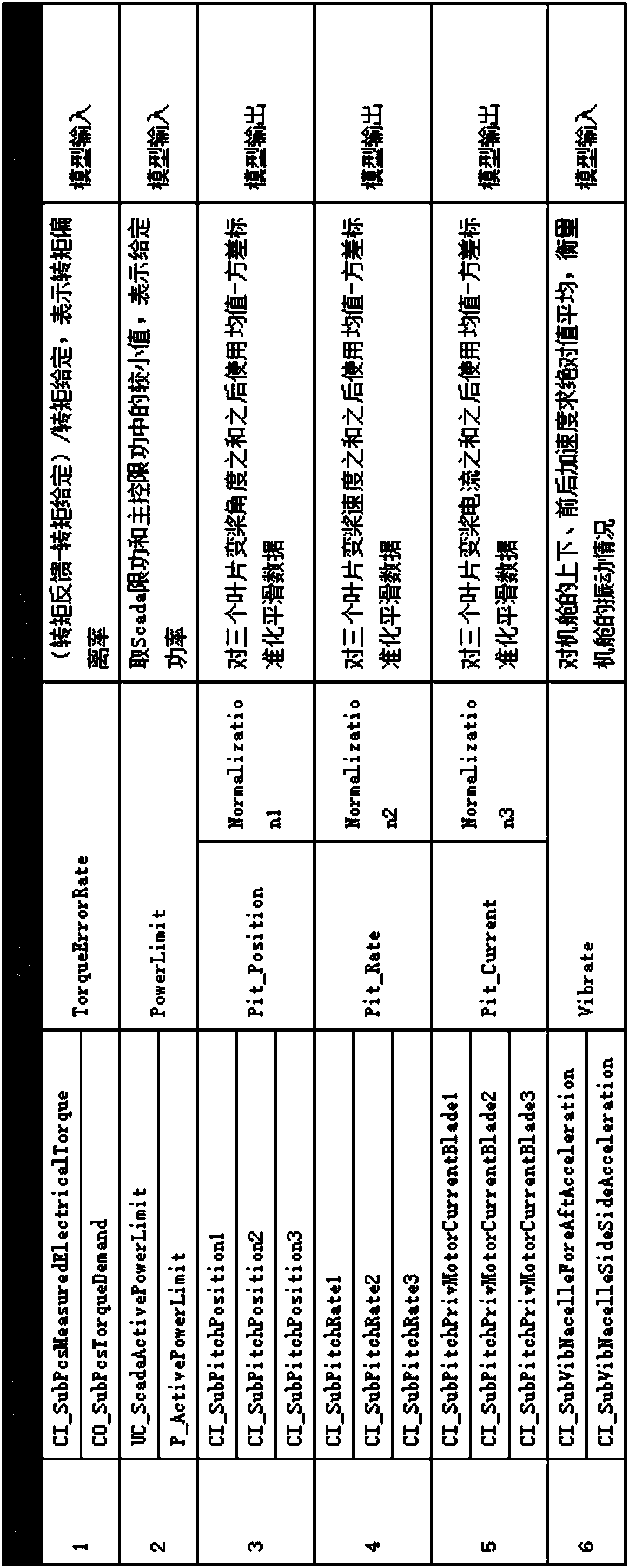

[0036] S01. Select multiple features of the wind turbine as input for preprocessing, and use the mean-variance standardization of the three variables describing the operating state of the blades as the output, and then sum them as output. The three variables are blade pitch angle, blade pitch speed and Blade pitch motor current value;

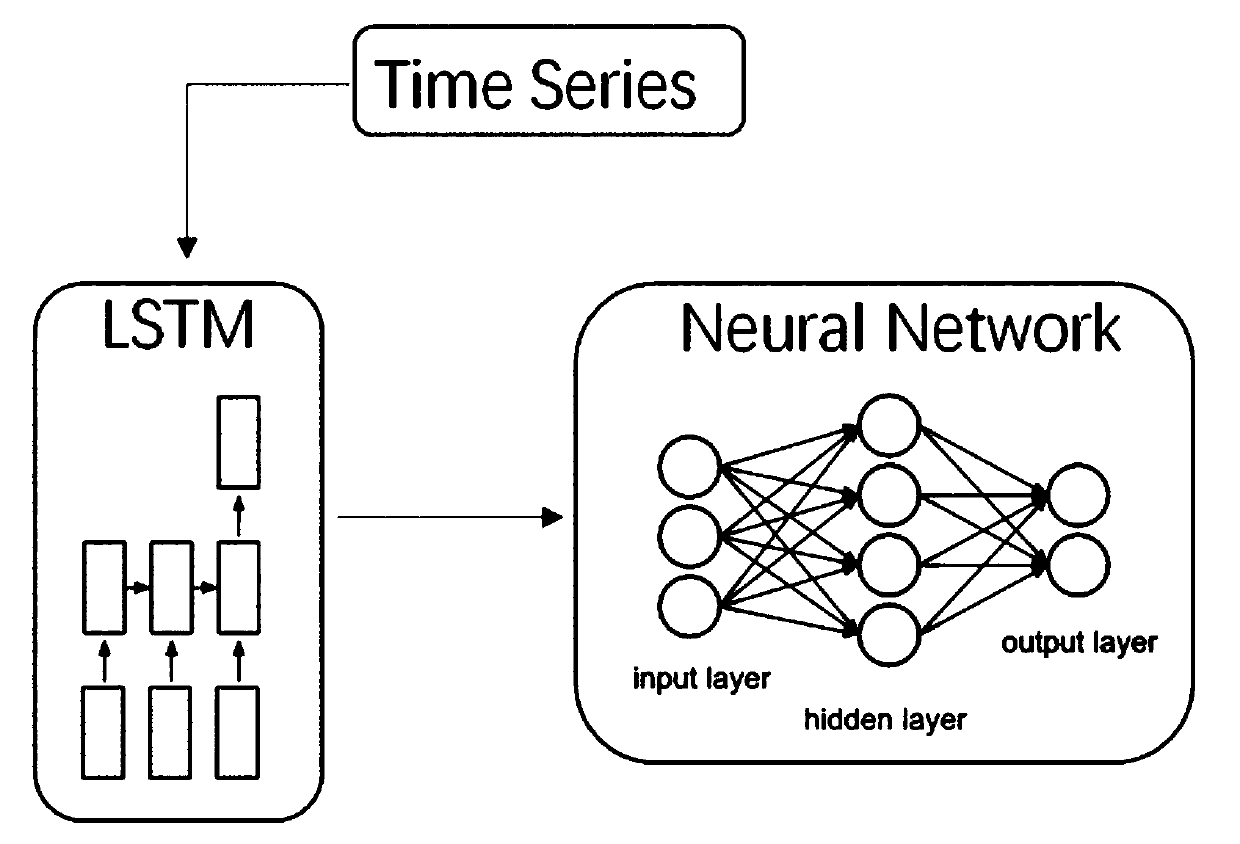

[0037] S02. Train the LSTM normal model using the data that has not had a blade root bolt fracture fault; use the data of the wind turbine with the blade root bolt fracture fault before the fault to train the LSTM fault model; input the data output from step S01 into the LSTM normal model and LSTM fault model to extract error vector features;

[0038] S03. Subst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com