Lifting device of camera and electronic equipment comprising same

A lifting device and electronic equipment technology, applied in the field of machinery, can solve the problems of easy generation of defective products, motor noise and vibration, power consumption, etc., and achieve the effects of fewer defective assemblies, low driving noise, and high retention force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

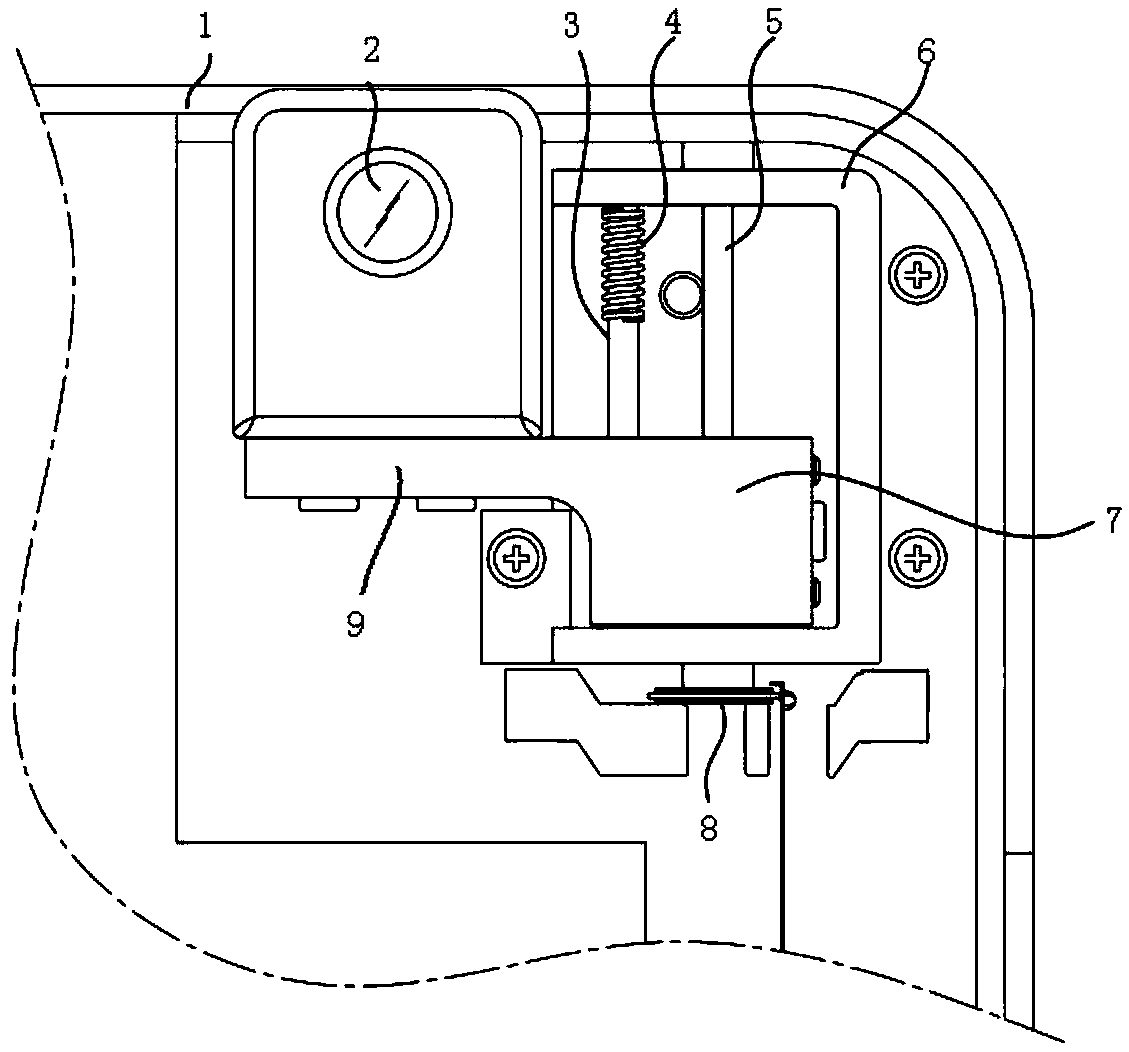

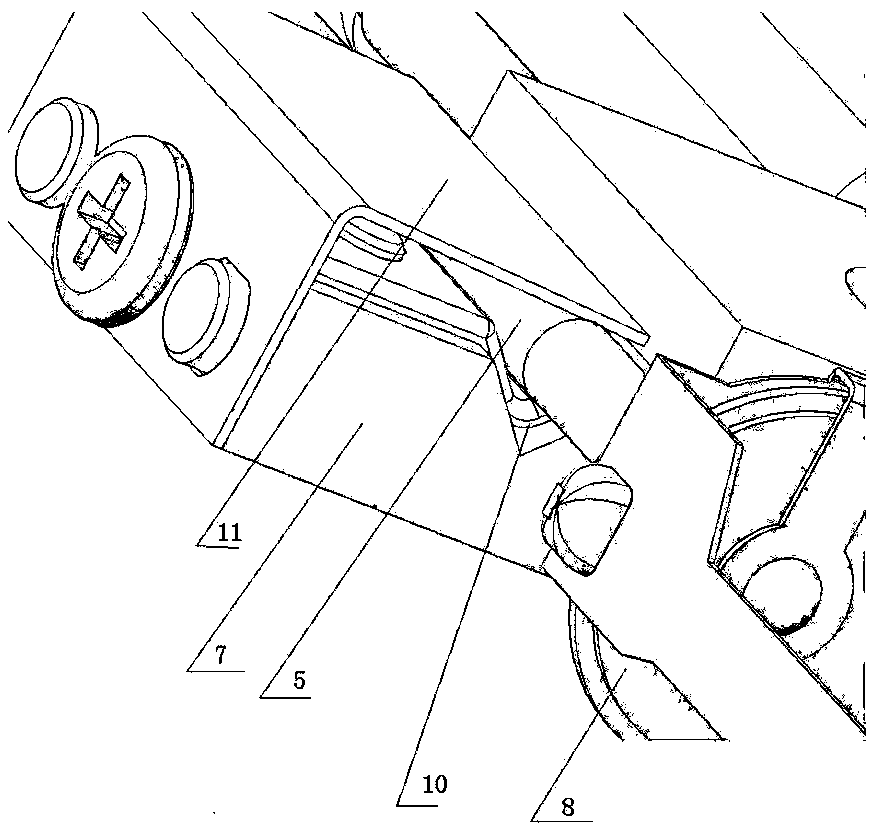

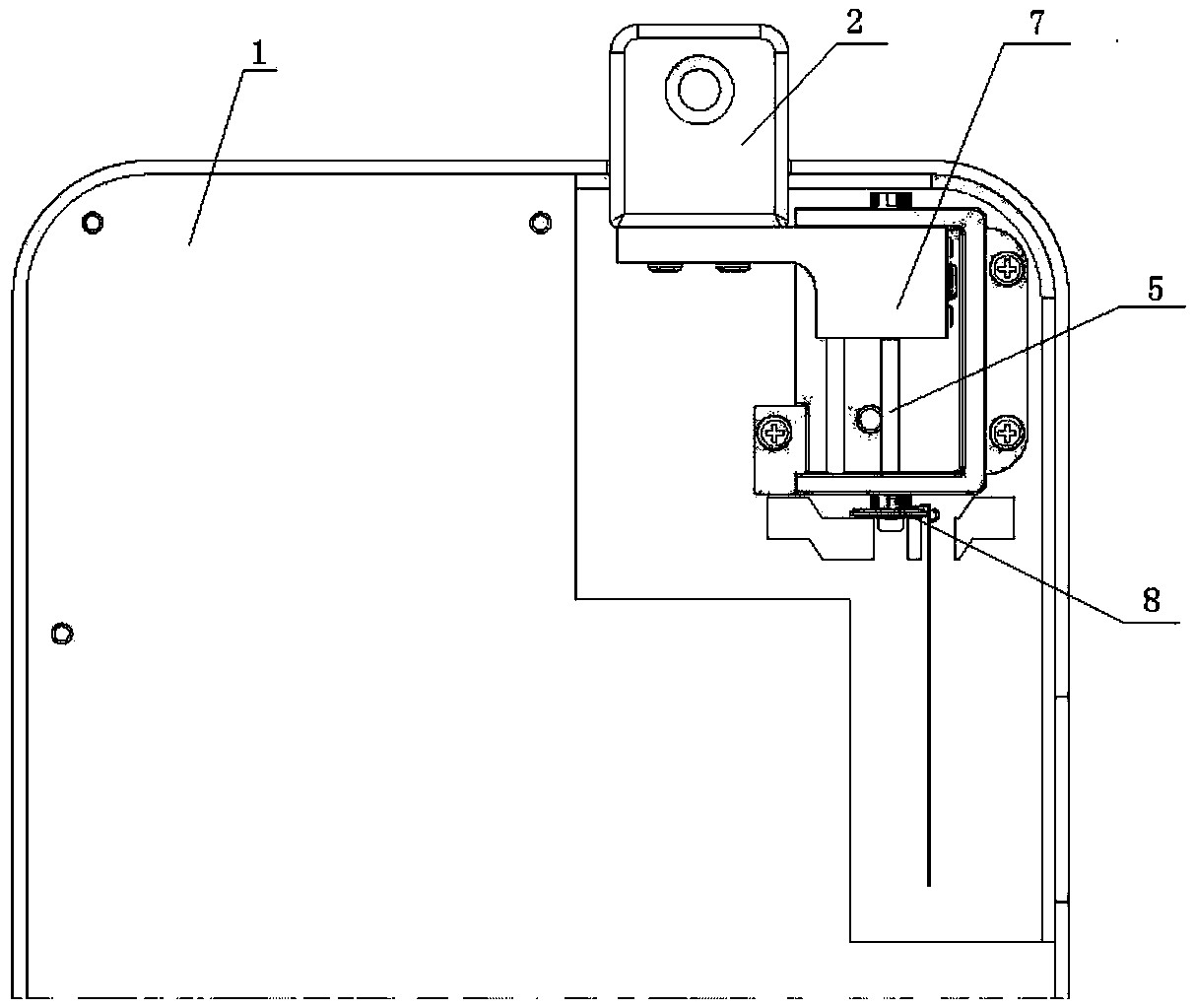

[0034] A lifting device for a camera, comprising a mounting frame 6, an ultrasonic motor assembly 8, a slider 7, a camera bracket 9, an auxiliary rod 3 and a spring 4, the ultrasonic motor assembly is installed on the mounting frame, and the sliding block is installed on the main shaft 5 of the ultrasonic motor. block, a card slot 10 is formed on the side of the slider, the main shaft is embedded in the slot, and a leaf spring 11 is fixed on the slider through bolts, the main shaft is clamped between the slider and the leaf spring, and the function of the leaf spring is to make the slider Tight fit between block and spindle. One end of the slide block is extended outwards to make a camera bracket integrally, and the camera 2 is fixedly mounted on the camera bracket. The slider slides up and down driven by the ultrasonic motor, and the camera slides up and down accordingly.

[0035] An auxiliary rod is fixed on the installation frame parallel to the main shaft at intervals, th...

Embodiment 2

[0039] The difference from Embodiment 1 is that two ultrasonic motors are used to drive the slider, such as Figure 5 As shown, the two ultrasonic motors are parallel and symmetrically installed on the installation frame, and the piezoelectric ceramic ends of the two ultrasonic motors are located on the lower side. Two auxiliary rods are adorned, and a spring is respectively set in the upper and lower sections of the two auxiliary rods.

Embodiment 3

[0041] The difference from Example 2 is that, as Image 6 As shown, one of the piezoelectric ceramic ends of the two ultrasonic motors is on the top and the other is on the bottom.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com