Heat radiation structure of microwave oven

A heat dissipation structure and technology for microwave ovens, applied in the field of microwave ovens, can solve the problems of air flow turning, high unit price, no noise, etc., and achieve the effects of reducing driving noise and vibration noise, reducing noise, and improving heat dissipation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

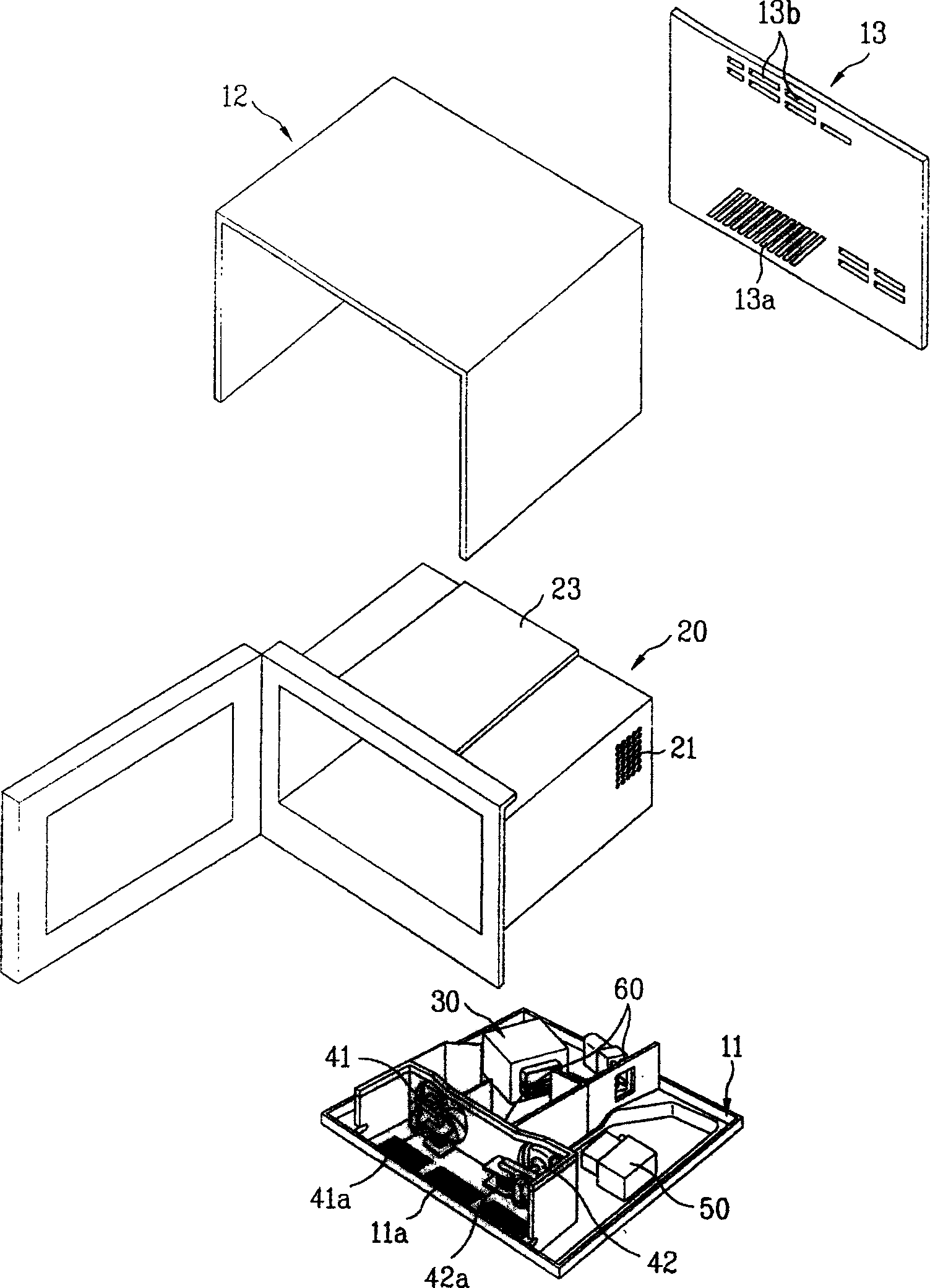

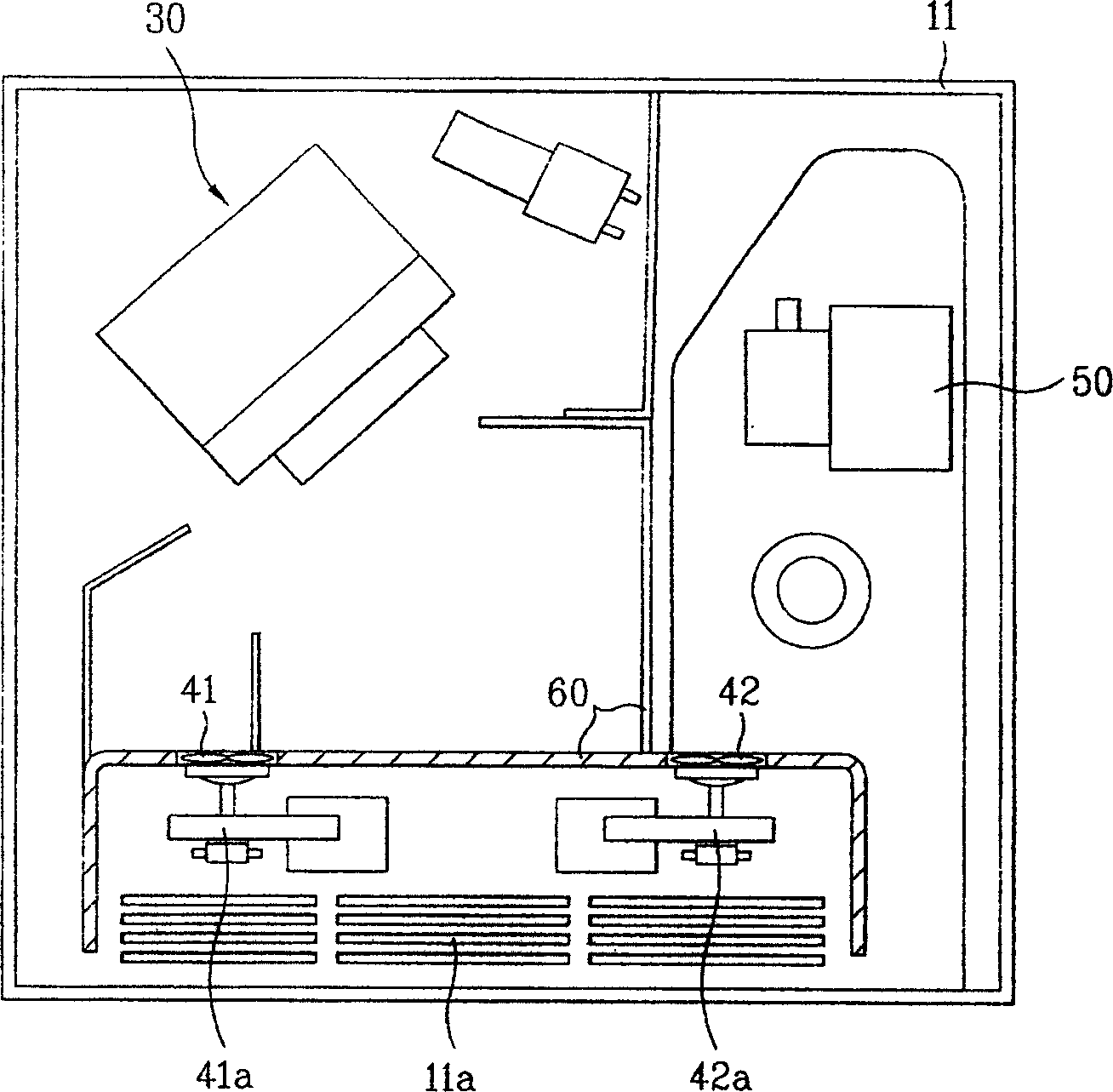

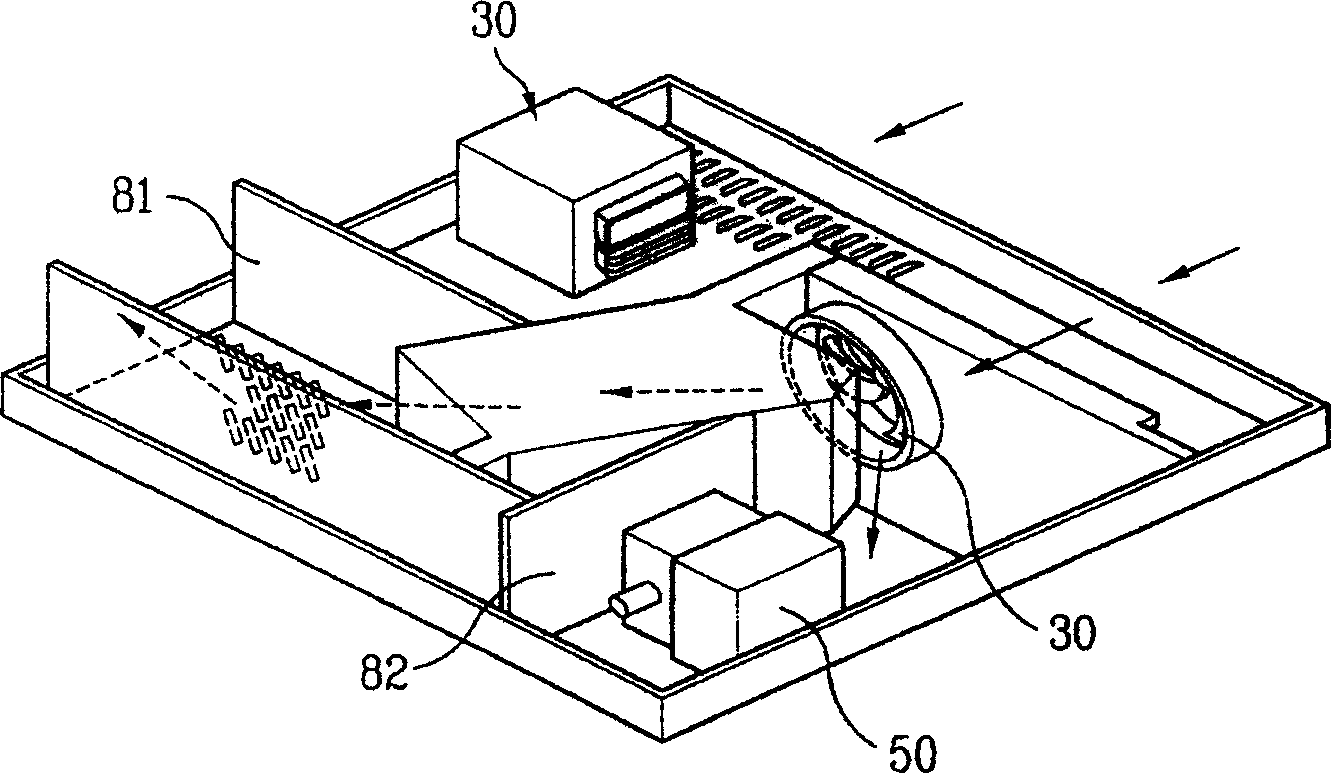

[0058] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail: Figure 5 A schematic exploded perspective view showing the structure of a microwave oven in an embodiment of the present invention. Image 6 A plan view showing the internal structure of a microwave oven in an embodiment of the present invention.

[0059] First, if Figure 5 and Image 6 As shown, the microwave oven in the embodiment of the present invention generally includes a body, a cabinet 200, an air guiding device 300, a high-voltage transformer 410, a magnetron 420, and an air supply device.

[0060] At the same time, a plurality of air inlets 111 , 131 and air outlets 121 , 132 , 133 are respectively formed on the fuselage.

[0061] Wherein, the air inlets 111, 131 communicate with the rear side space in the lower space inside the fuselage; the air outlets 121, 132, 133 communicate with the front side space in the lower space inside t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com