Manufacturing method of sintering-free parallel flow heat exchanger

A technology of parallel flow heat exchanger and manufacturing method, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problem of increasing the cost and development space of parallel flow evaporators in small batches, high cost of composite aluminum foil, low bundling efficiency, etc. To solve the problem of low bundling efficiency, reduce production costs and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0009] Preparation of the present invention comprises the following steps:

[0010] Step 1: Make fins, the fins are made of holes in the middle of the aluminum foil, and there are flanging at the holes;

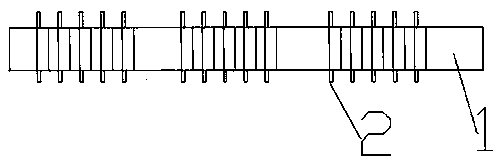

[0011] Step 2: Insert the harmonica tube into the interference fit connection through the hole on the fin;

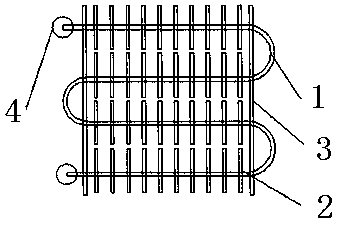

[0012] Step 3: Bending step 2, and installing fixed end plate brackets at both ends of the bending;

[0013] Step 4: Manually weld the flow-collecting tube and the connecting tube at both ends of the harmonica tube to form a parallel-flow heat exchanger.

Embodiment 2

[0015] To make the fins, punch holes along one side of the aluminum foil, and flang the holes. The length of the aluminum foil is based on the number of S-shaped bends of the harmonica tube, and the fins are placed into the pendulum according to certain rules.

[0016] Fold the harmonica tube into an S-shaped bend corresponding to the opening of the fin, press it into the fin through a hydraulic press or a special plane, and fix it on the fin group;

[0017] The inner diameter of the fin opening is smaller than the outer diameter of the harmonica tube, the purpose is to connect more closely, interference fit, to reduce thermal resistance;

[0018] A parallel-flow evaporator is formed by adding end plates to the harmonica tubes fixed with fins, welding flow-collecting tubes, and connecting tubes.

[0019] The thickness of the aluminum foil is 0.1-0.3 mm, preferably 0.15 mm in this technical solution.

[0020] The harmonica pipe is folded into an S-bend as required.

[0021] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com