Intermediate shaft spiral gear meshing position degree gauge

An intermediate shaft and helical tooth technology is applied in the field of intermediate shaft helical tooth-to-tooth position degree inspection tools, which can solve the problems of time-consuming, labor-intensive, and easily damaged measurement process, and achieve the effect of convenient process quality, convenient operation, and convenient process quality control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

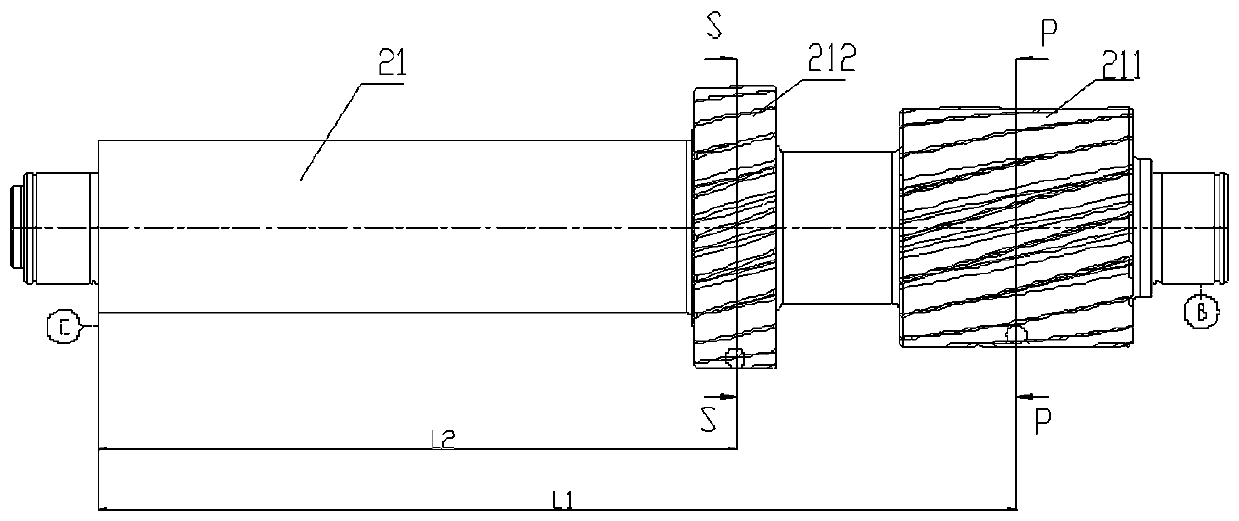

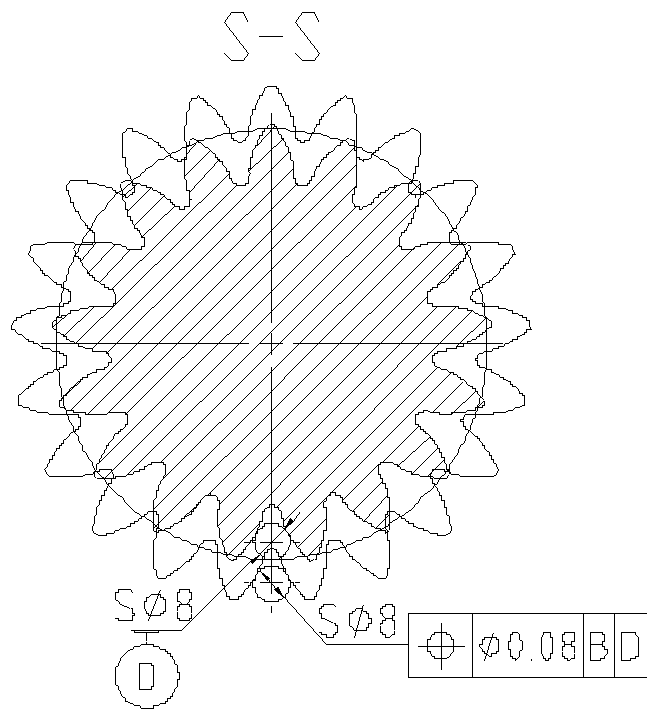

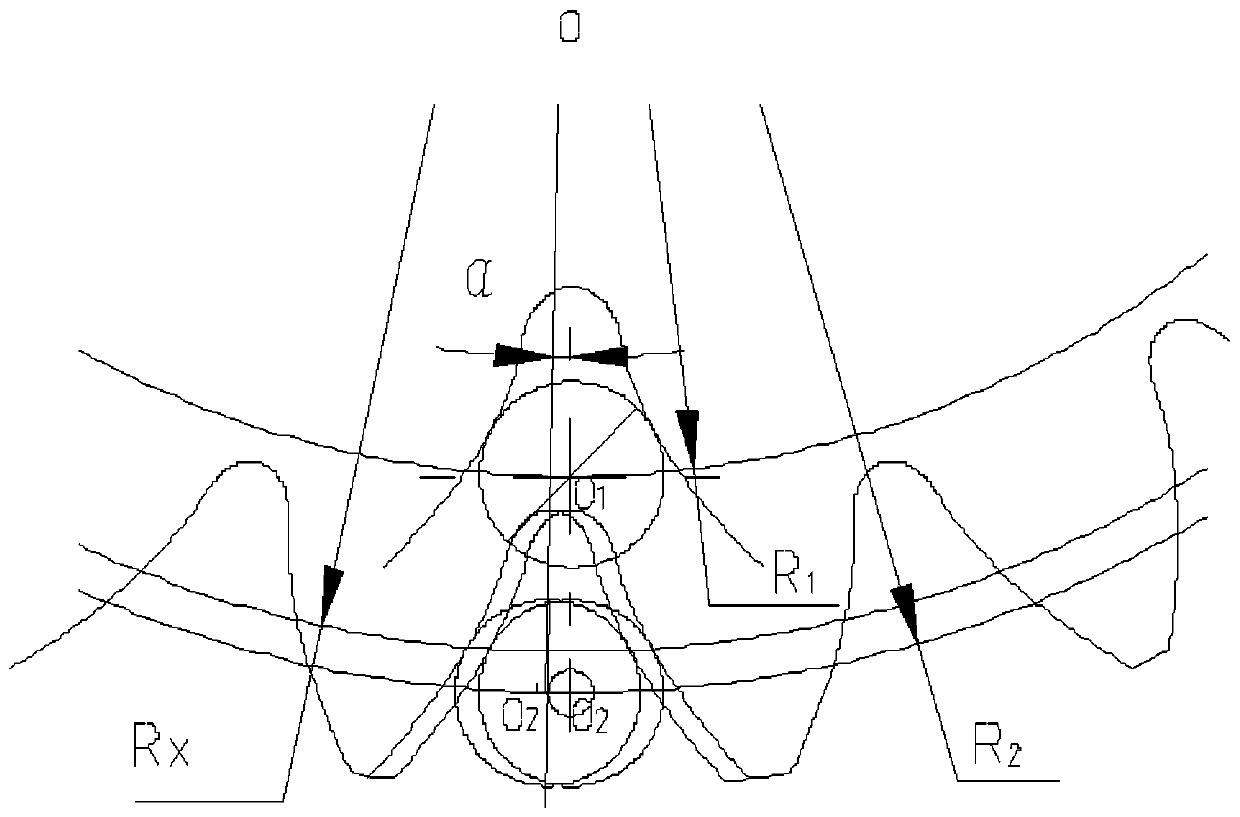

[0028] see Figure 4 and Figure 5 , the present invention provides an intermediate shaft helical tooth-to-tooth position inspection tool, including an auxiliary measuring device and a base 17, the base 17 is fixed with a support block 18 for supporting the intermediate shaft 21, and the two support blocks 18 are respectively located in the middle The two shaft ends of the shaft are used to locate the outer circle and the end face of the intermediate shaft. The base 17 is also fixed with a support 3 on the side of the intermediate shaft. The first pin 15 of the upper first tooth 211, and the second pin 2 for positioning the second tooth 212 on the intermediate shaft; the auxiliary measuring device is fixed on the intermediate shaft 21, and the auxiliary measuring device rotates with the rotation of the intermediate shaft 21 , the auxiliary measuring device is provided with an engraved marking surface extending along the radial direction of the intermediate shaft 21 .

[0029...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com