Chip used for realizing structure activity relationship indirect in-situ characterization with TEM and manufacturing method thereof

A manufacturing method and chip technology, applied in the preparation of test samples, material analysis using radiation, instruments, etc., can solve problems such as the inability to correlate material structure with material physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

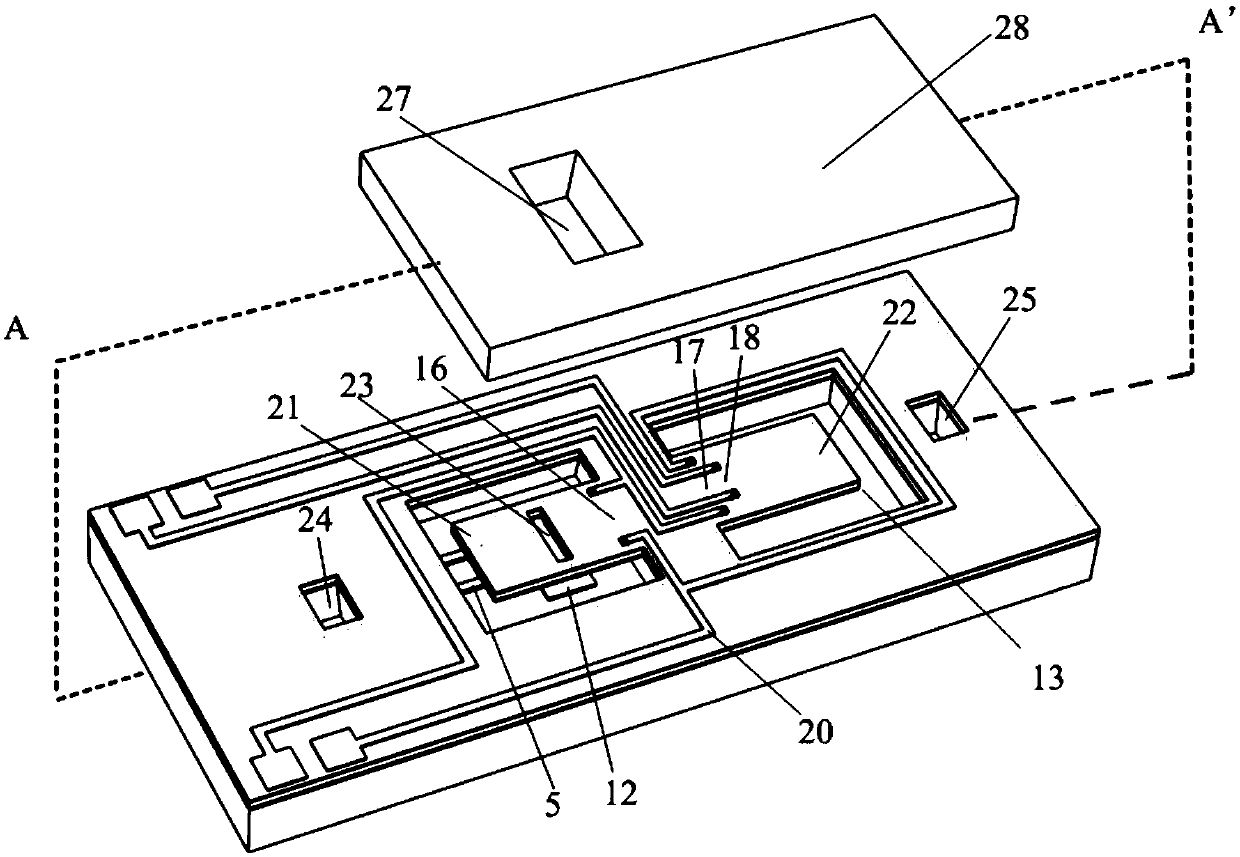

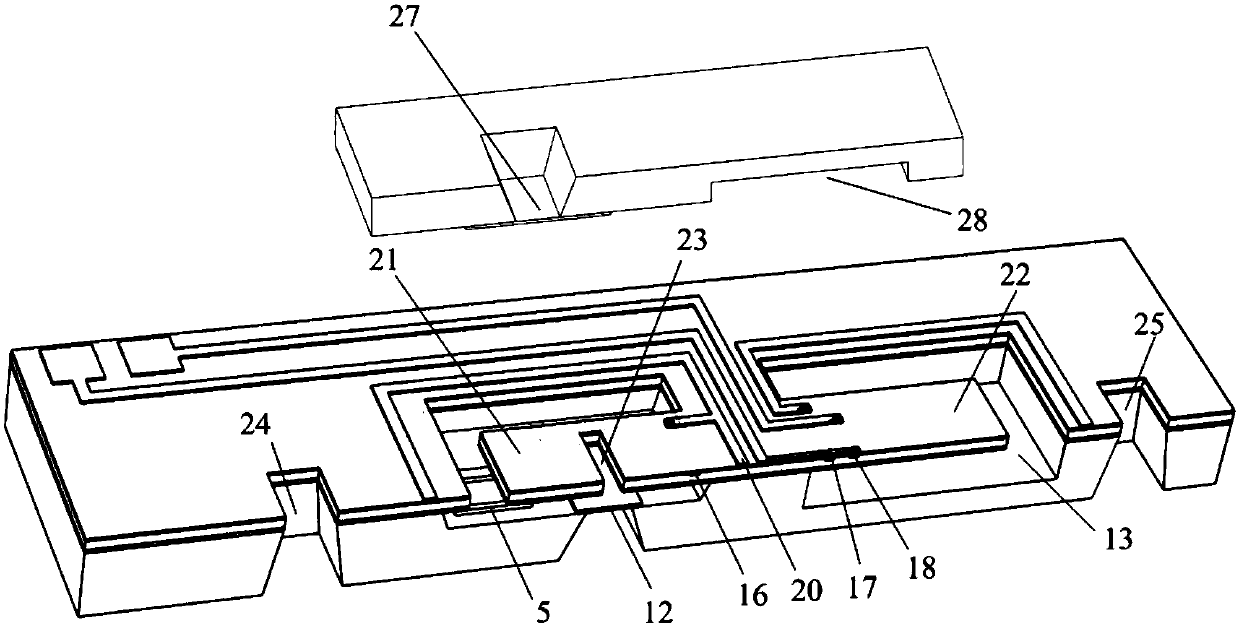

[0085] refer to Figure 1 ~ Figure 4 , this embodiment provides a chip for indirect in situ characterization of TEM structure-activity correlation, the chip includes a main chip and a secondary chip, wherein the main chip includes:

[0086] A detection cantilever beam 22, through which the resonance of the detection cantilever beam 22 is used to detect the mass change of the sample to be measured located on the detection cantilever beam 22;

[0087] The main chip groove 13, the main chip groove 13 is located under the detection cantilever beam 22, and the resonance of the detection cantilever beam 22 is provided by the main chip groove 13 to accommodate the space;

[0088] Observation cantilever beam 21, described observation cantilever beam 21 comprises observation hole 23;

[0089] Main chip window, the main chip window 12 is located below the observation hole 23;

[0090] Air holes, the air holes are located on the outside of the detection cantilever beam 22 and the obser...

Embodiment 2

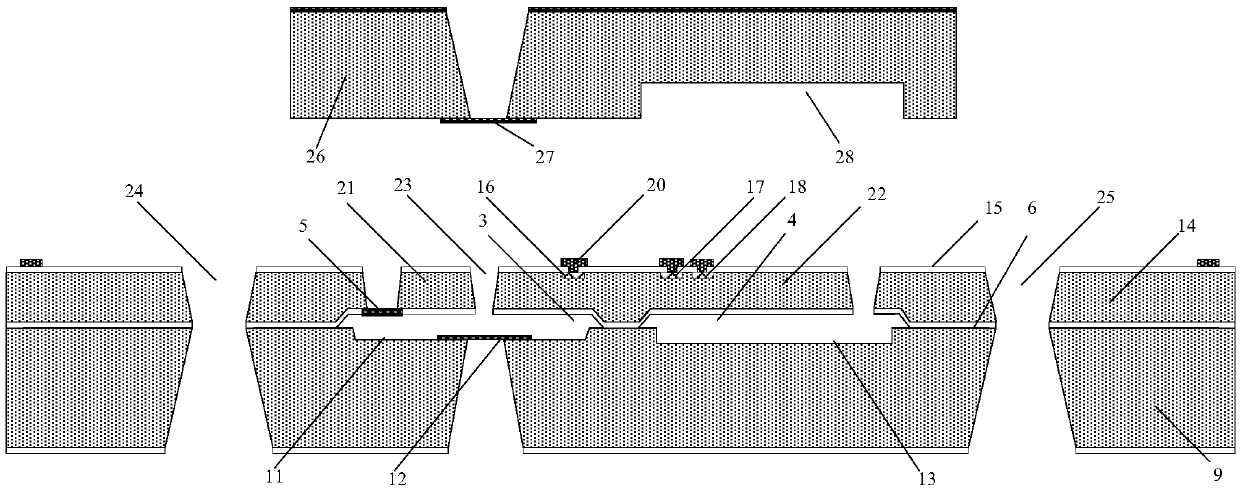

[0114] This embodiment also provides a method for manufacturing a chip for indirect in-situ characterization of TEM structure-activity correlation, the chip includes a main chip and an auxiliary chip, wherein making the main chip includes the following steps:

[0115] Provide the main chip substrate;

[0116] Fabricate a detection cantilever beam, a main chip groove, an observation cantilever beam, a main chip window, and an air hole in the main chip substrate; wherein, the main chip groove is located below the detection cantilever beam, passing through the main chip groove Provide accommodation space for the resonance of the detection cantilever beam; the observation cantilever beam includes an observation hole; the main chip window is located below the observation hole; the air hole is located outside the detection cantilever beam and the observation cantilever beam and runs through The main chip, the air hole includes a main chip air inlet and a main chip air outlet; the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com