A multi-objective pneumatic optimization design method for a transonic axial fan/compressor

An optimized design, axial flow fan technology, applied in multi-objective optimization, calculation, special data processing applications, etc. Strengthen the practical significance of engineering, solve the effect of pressure ratio and efficiency, and shorten the design cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

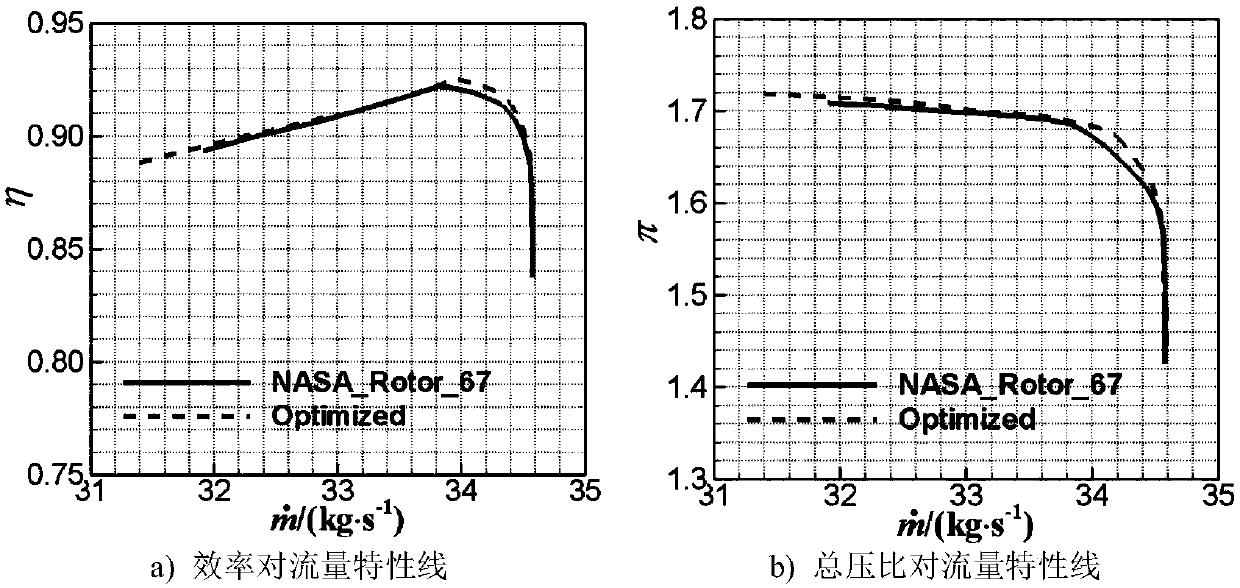

[0027] This embodiment is based on the NASA Rotor 67 fan rotor (its main design parameters are shown in Table 1), taking its design scheme as a blueprint, and applying a multi-objective aerodynamic optimization design method for a transonic compressor proposed by the present invention to complete the multi-objective aerodynamic design optimization.

[0028] Table 1 Main design parameters of NASA Rotor 67

[0029]

[0030]

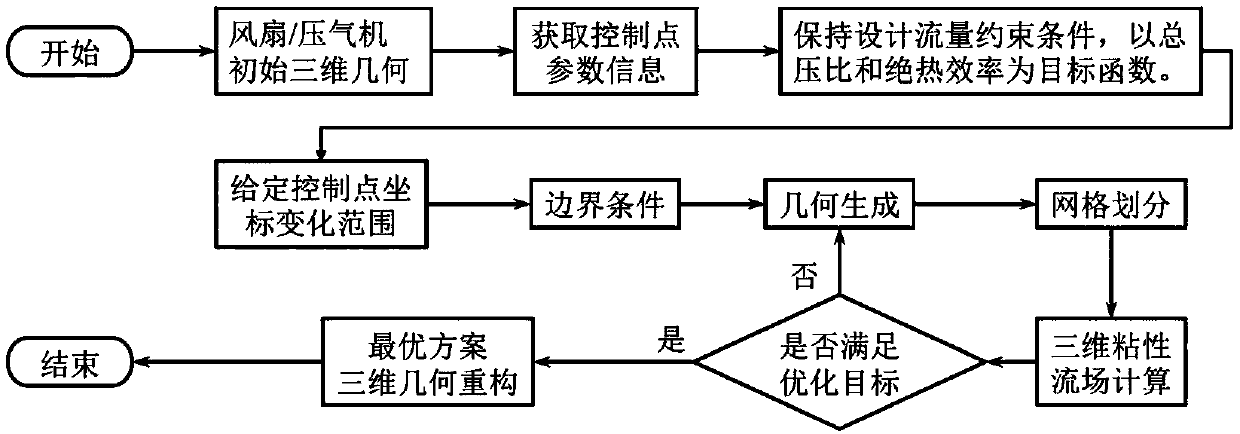

[0031] refer to figure 1 , the specific implementation steps are as follows:

[0032] Step 1: First obtain the three-dimensional geometric data of the rotor blade channel of the NASA Rotor 67 fan, use it as the initial design data and perform parameterization.

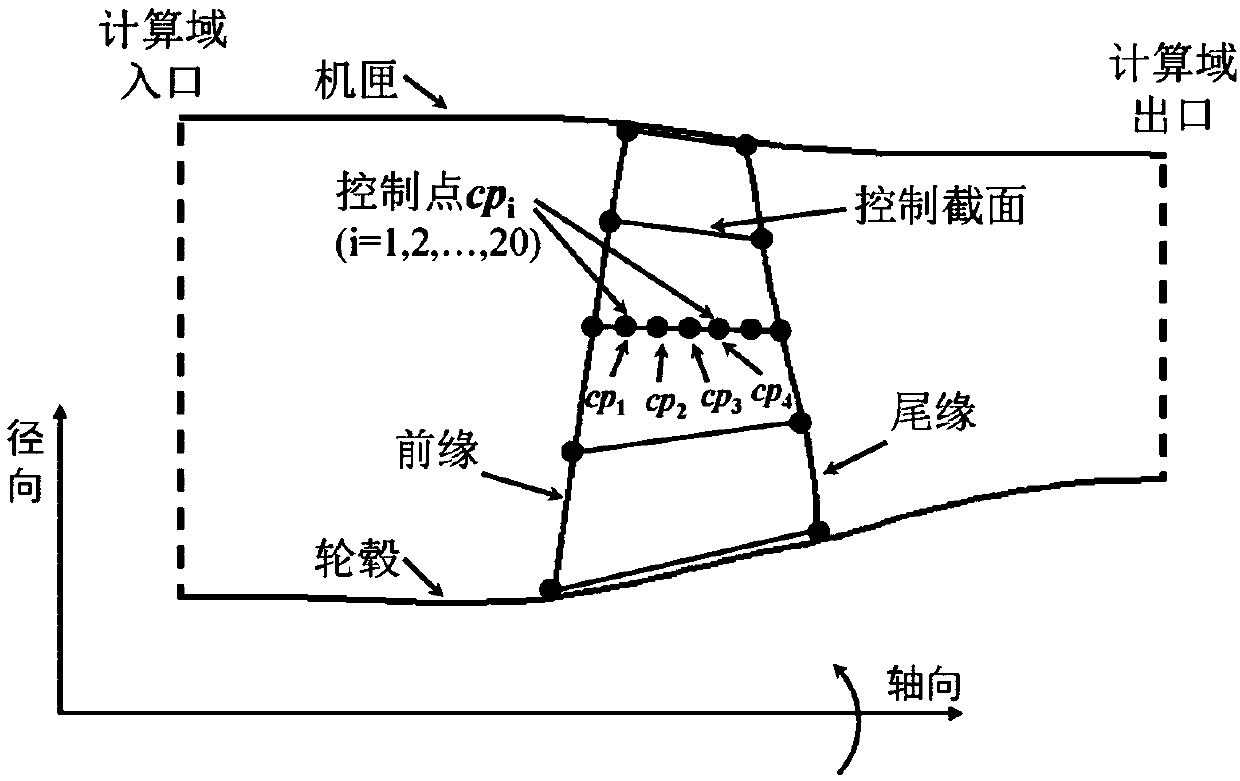

[0033] In the stage of parameterizing the three-dimensional geometry of the blade channel, the number of parameterized control points for each blade section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com