Collimator and double-perspective imaging system

An imaging system and collimator technology, applied in the field of scanning imaging, can solve problems such as unfavorable modularization and refinement of the scanning system, occupying a large amount of space in the scanning system, increasing the difficulty of manufacturing, etc., achieving good imaging effects and simplifying the adjustment process , the effect of reducing the difficulty of manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

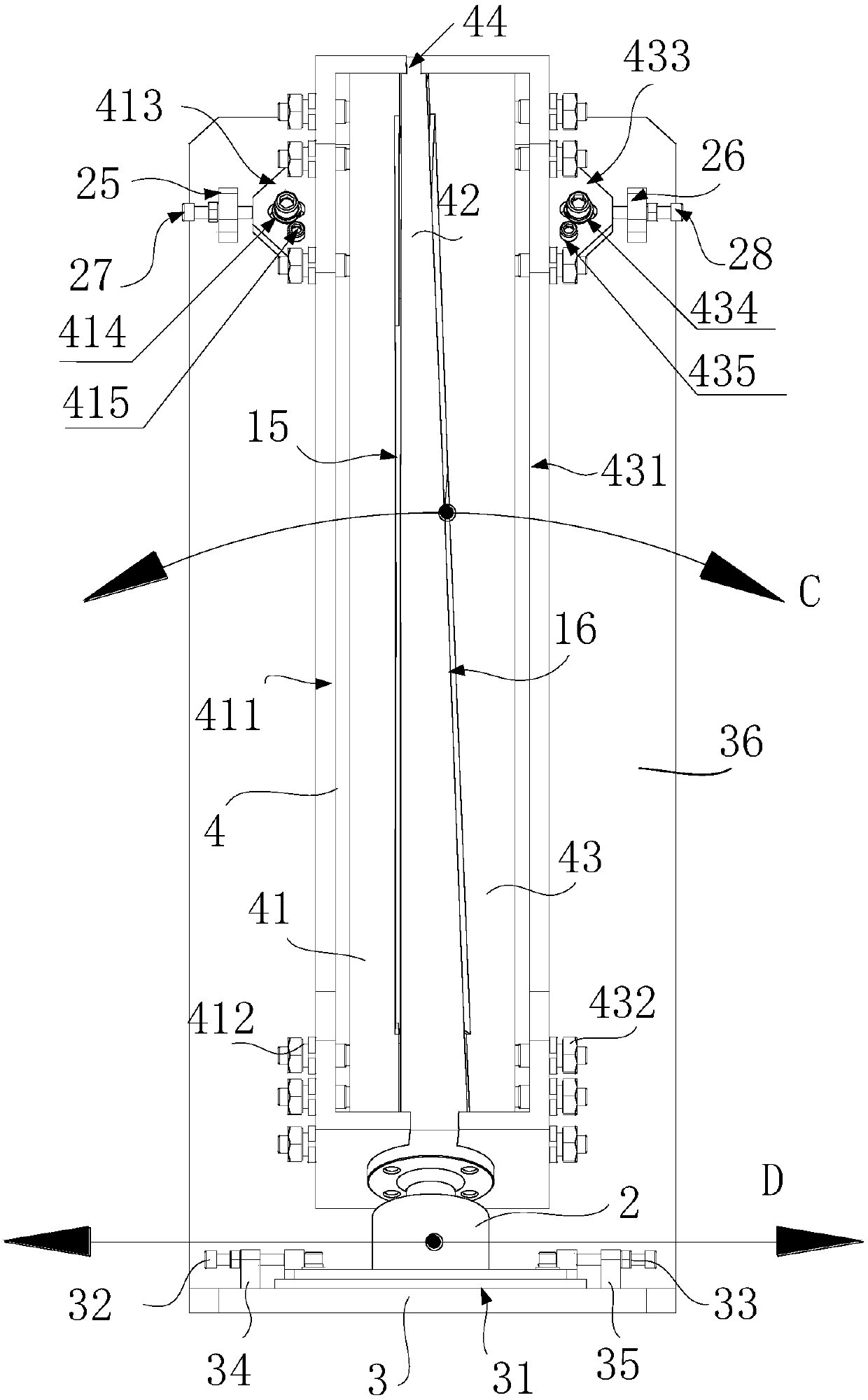

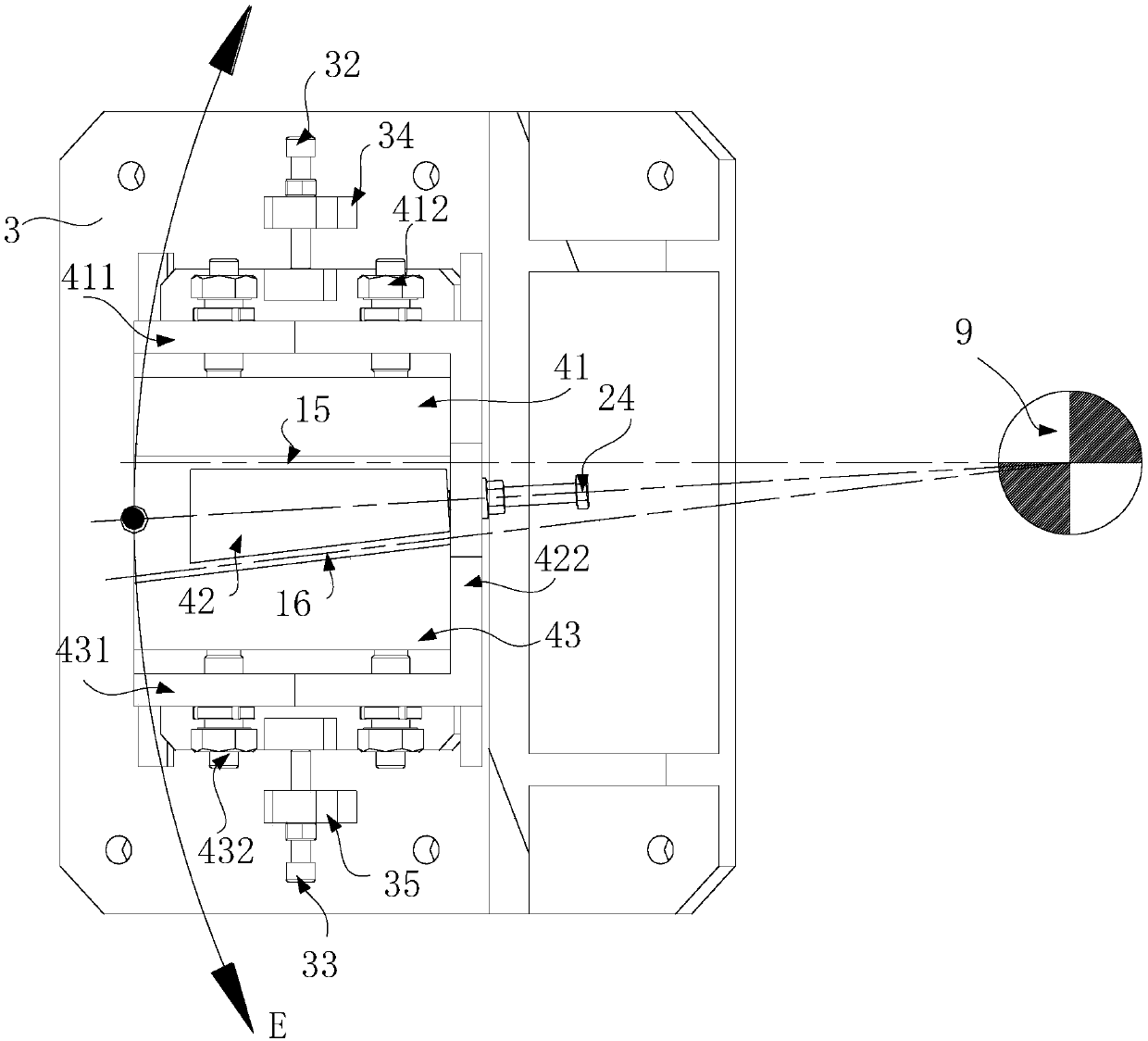

[0042] Such as figure 2 As shown, this embodiment provides a specific implementation method for adjusting the sliding of the mounting base 2 on the mounting surface 31: the collimator also includes a first adjusting stud 32 and a second adjusting stud 33, and the mounting surface 31 is installed with respectively The first adjustment plate 34 and the second adjustment plate 35 are located on both sides of the mounting base 2 .

[0043] The first adjustment stud 32, the second adjustment stud 33, the first adjustment plate 34, and the second adjustment plate 35 form a first adjuster, the first adjustment plate 34 is provided with a first threaded hole, and the second adjustment plate 35 There is a second threaded hole on the top, and the first adjusting stud 32 abuts on the mounting seat 2 after passing through the first threaded hole; the second adjusting stud 33 abuts on the mounting seat 2 after passing through the second threaded hole. 2 on. The first adjusting stud 32 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com