Infrared generator

An infrared generator, infrared radiation technology, applied in the direction of ohmic resistance electrodes, heating elements, heating element materials, etc., can solve the problems of low safety, unconcentrated energy, reduced radiation power energy density, etc., to improve the aggregation effect, The effect of reducing the overall power and reducing the overall size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

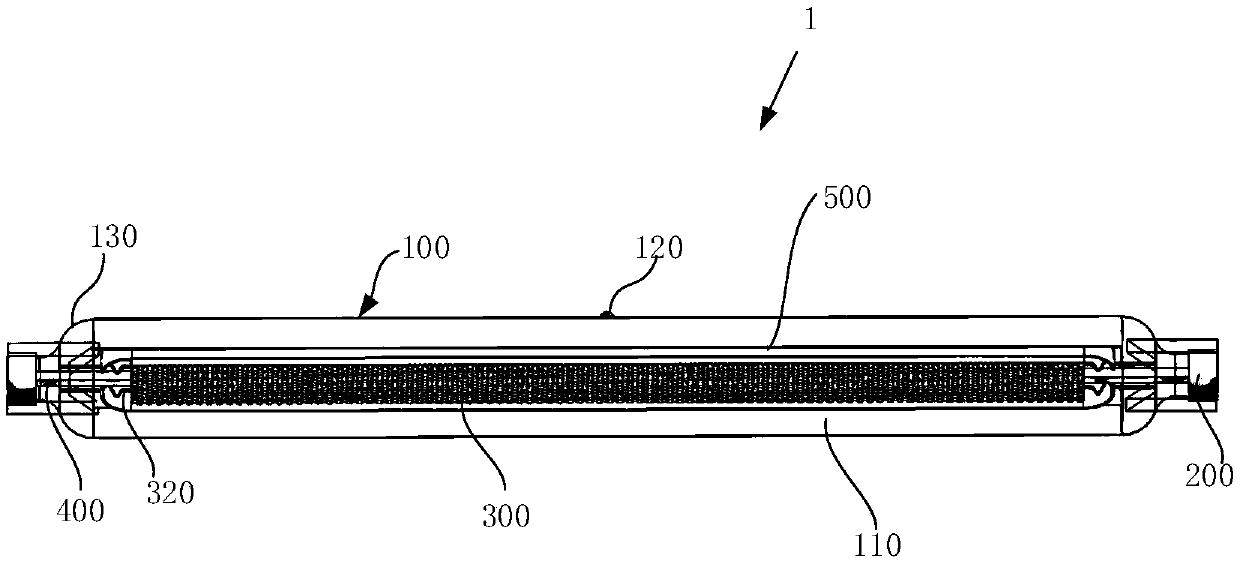

[0055] figure 1 It is the structural representation of the infrared generator involved in the embodiment;

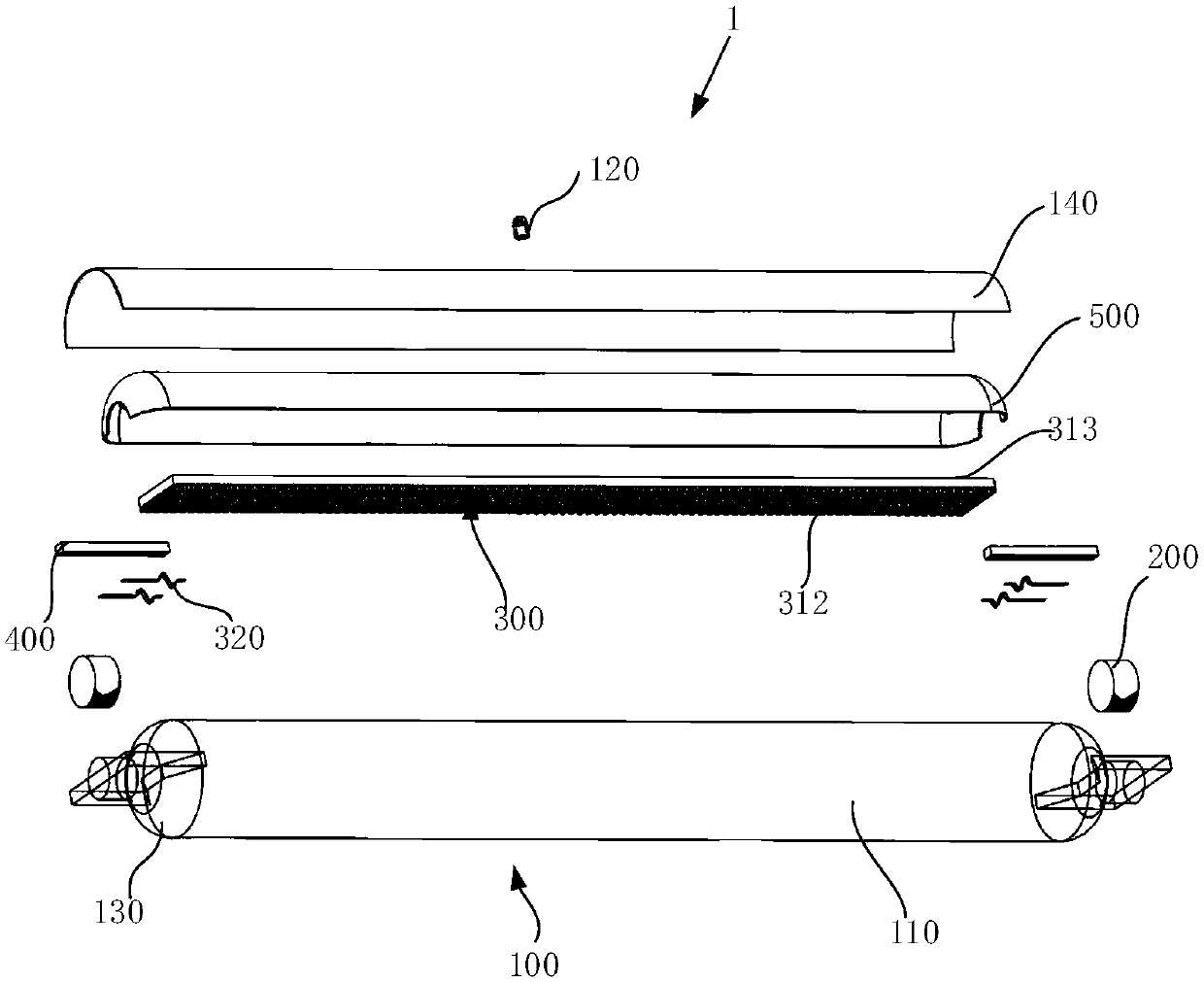

[0056] figure 2 It is an exploded exploded view of the infrared generator involved in the embodiment.

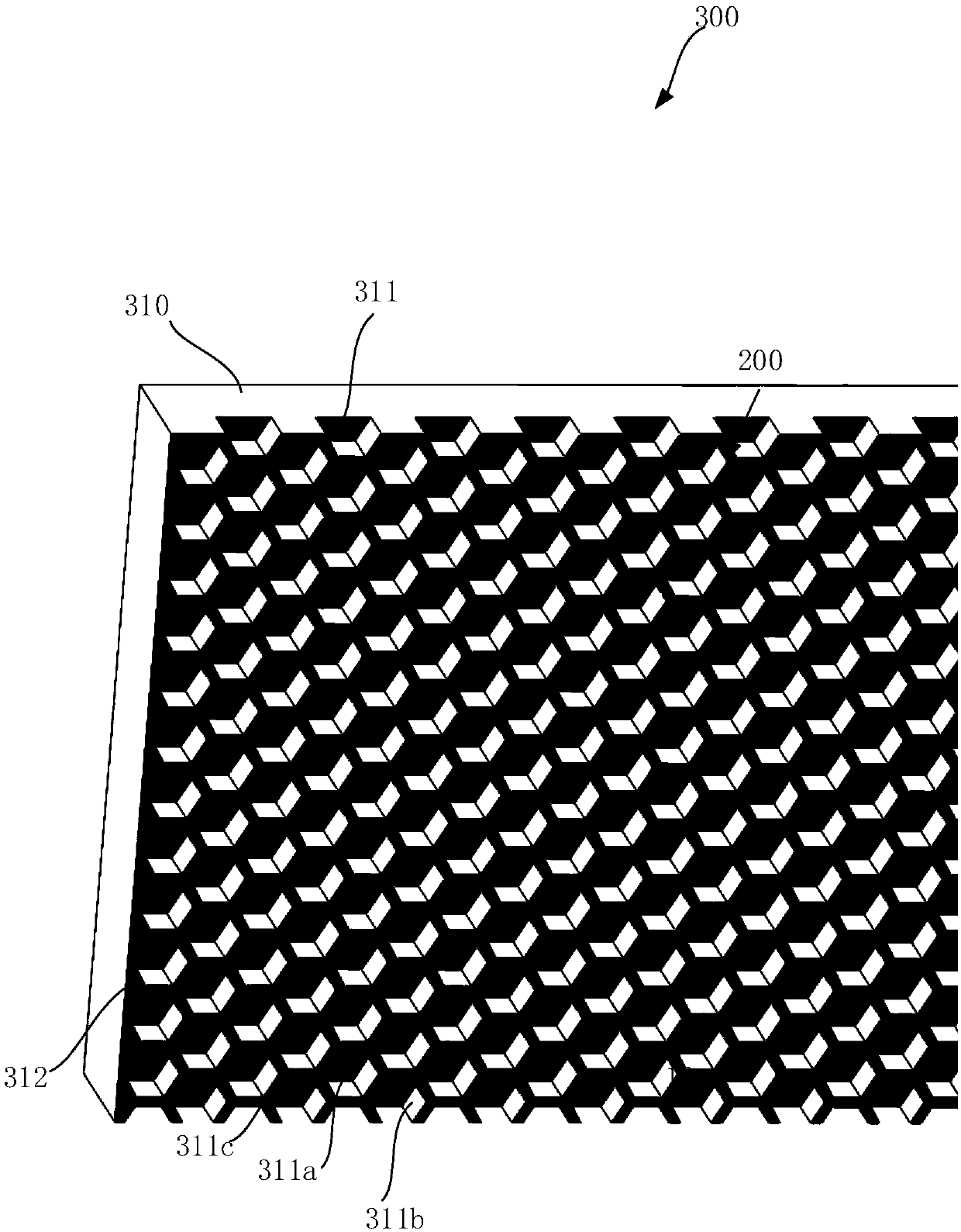

[0057] The infrared generator 1 provided in this embodiment includes: a quartz container 100 , two external electrodes 200 , an infrared radiation element 300 , two internal electrodes 400 and an infrared reflection element 500 .

[0058] The quartz container 100 has an internal cavity 110, and the internal cavity 110 is a vacuum. In this embodiment, the range of the vacuum degree of the internal cavity 110 is less than or equal to 1 Torr (torr). At this time, it can be considered that the heat of the internal cavity 110 Convection is eliminated, thereby reducing heat loss to produce mainly the required infrared radiation. The appearance of the quartz container 100 can be in various shapes, as long as the wall is sealed so that the inner cavity 110 forms a vacuum s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com