Alternating current powder charge eliminator and powder delivery pipeline charge eliminating system

A technology of charge elimination and conveying pipelines, applied in conveyors, conveying bulk materials, static electricity, etc., can solve the problems of inconvenient production, installation and use, inconvenient ion output characteristics, unsatisfactory power dissipation efficiency, etc. The effect of improving electrical efficiency and ensuring discharge safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

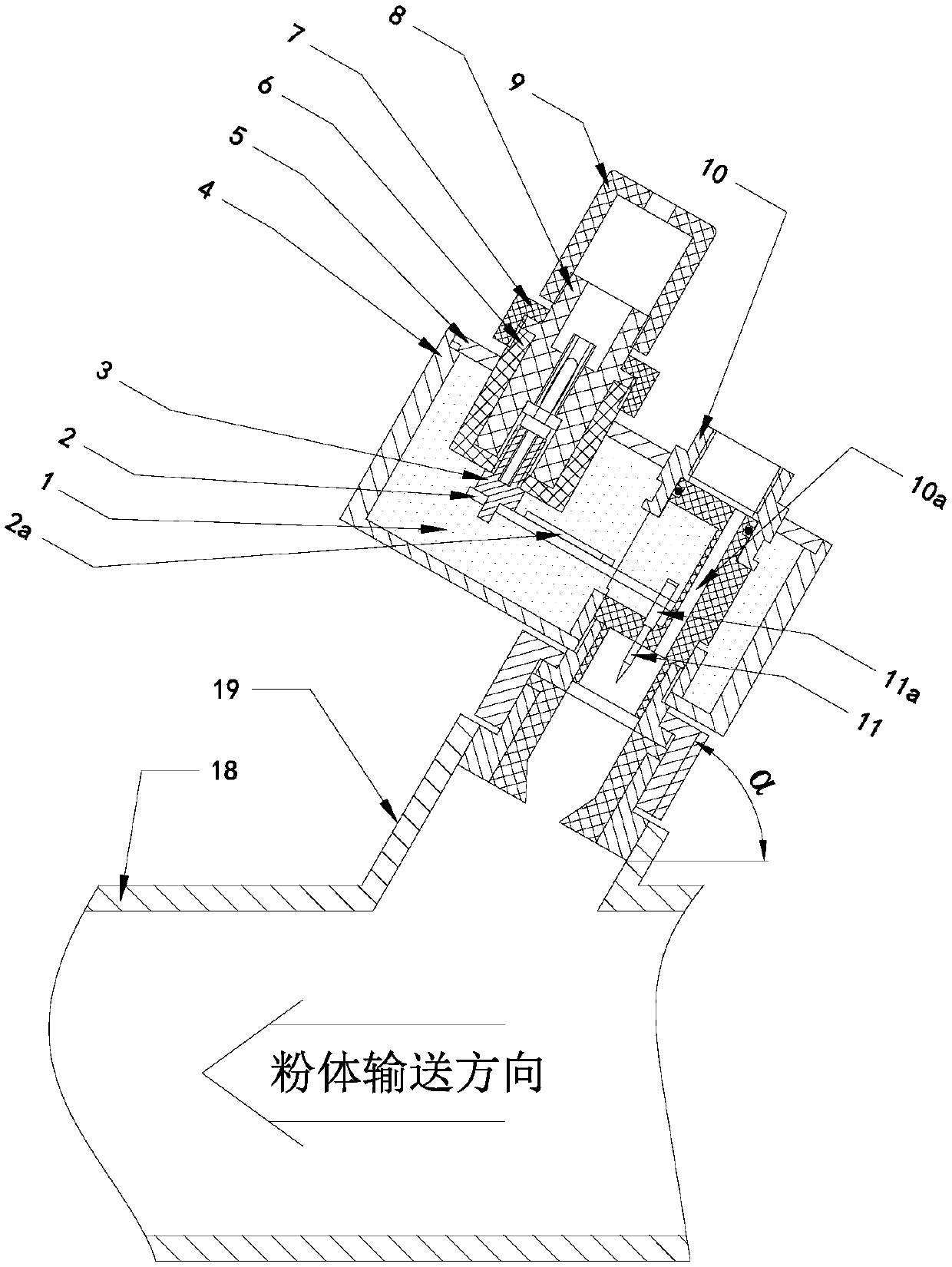

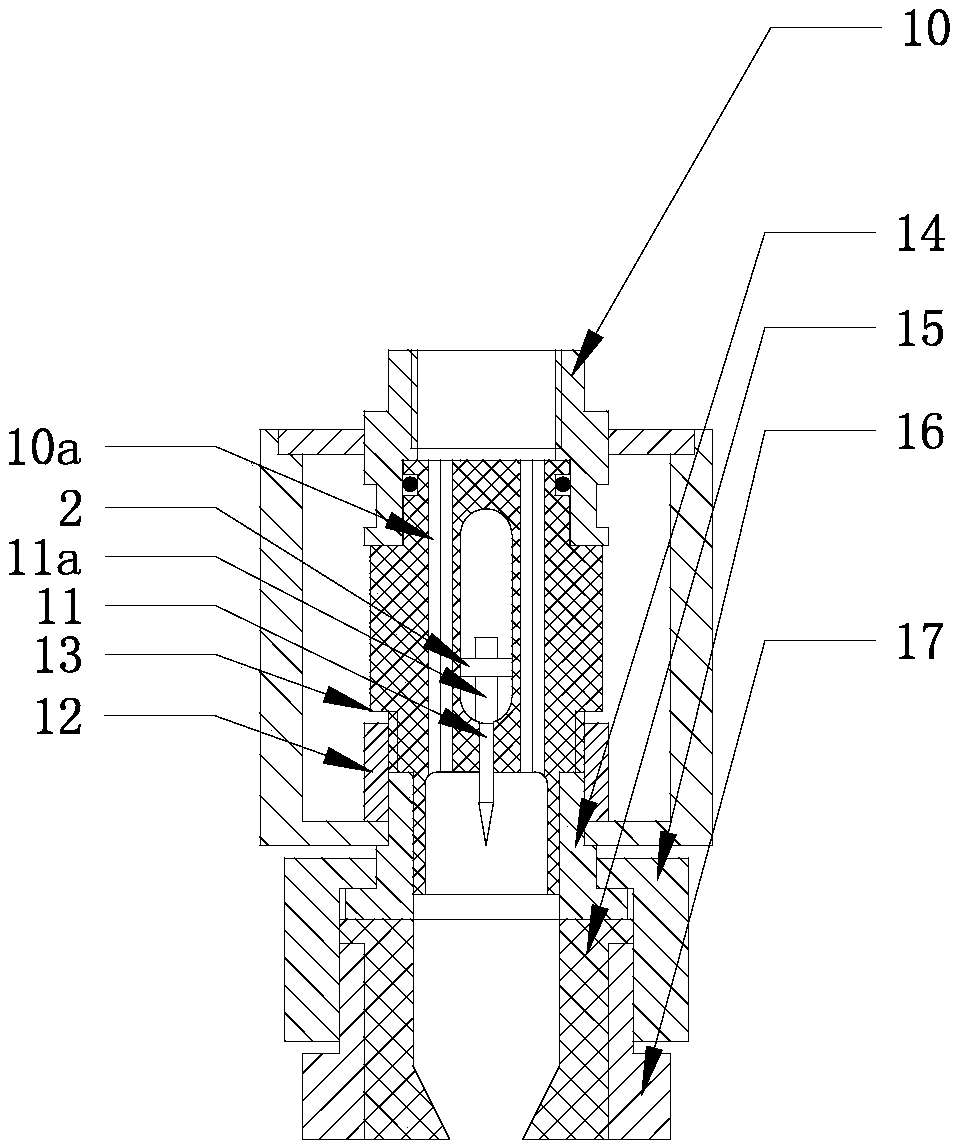

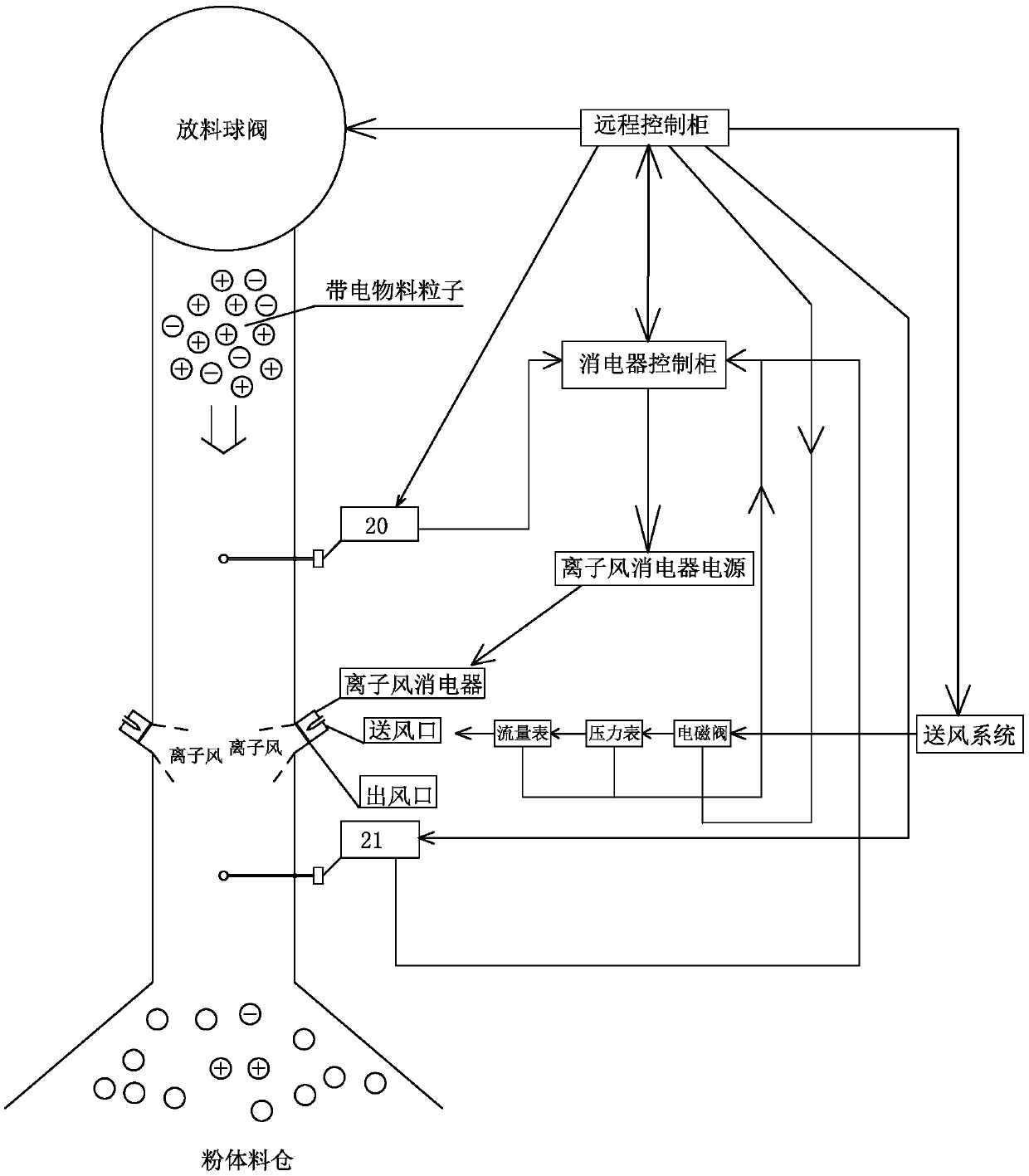

Method used

Image

Examples

Embodiment

[0179] After adopting this technical solution, it has been compared with existing commercially available products, and its comparison result is as follows:

[0180]

[0181] From the above table, it can be seen that under the same pipe diameter, the same type of powder conveyed, and the same conveying conditions, the powder static eliminator applying the patented technical solution has a significantly improved electricity dissipation efficiency.

[0182] The invention can be widely used in the field of design and manufacture of the electricity dissipating device of the powder conveying system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com