Adhesive composition, adhesive film, and method for utilizing same

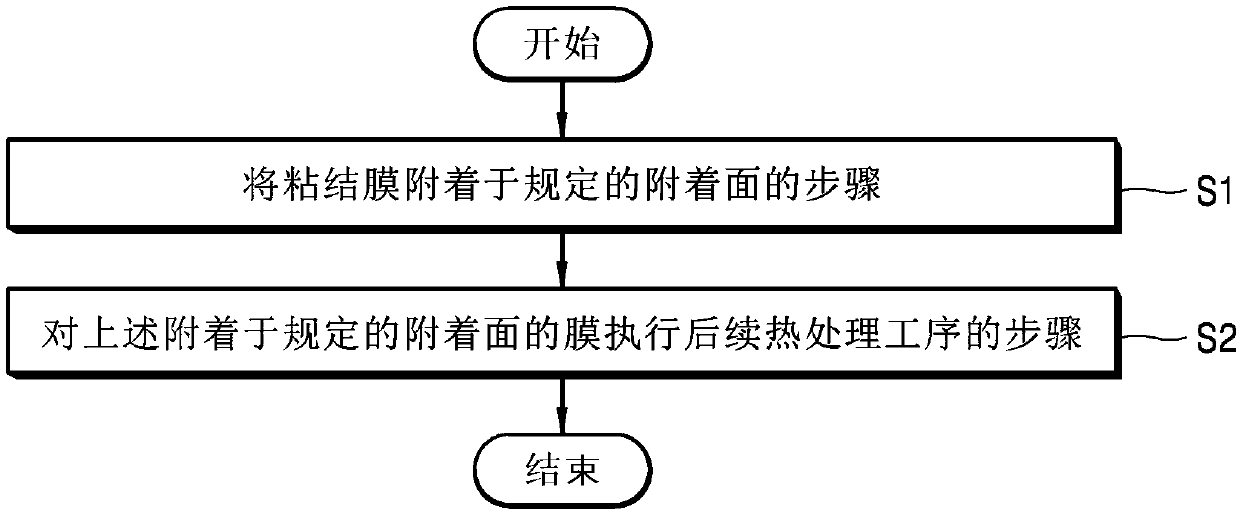

A bonding composition, bonding film technology, applied in the direction of bonding method of adhesive heating, adhesive type, ester copolymer adhesive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

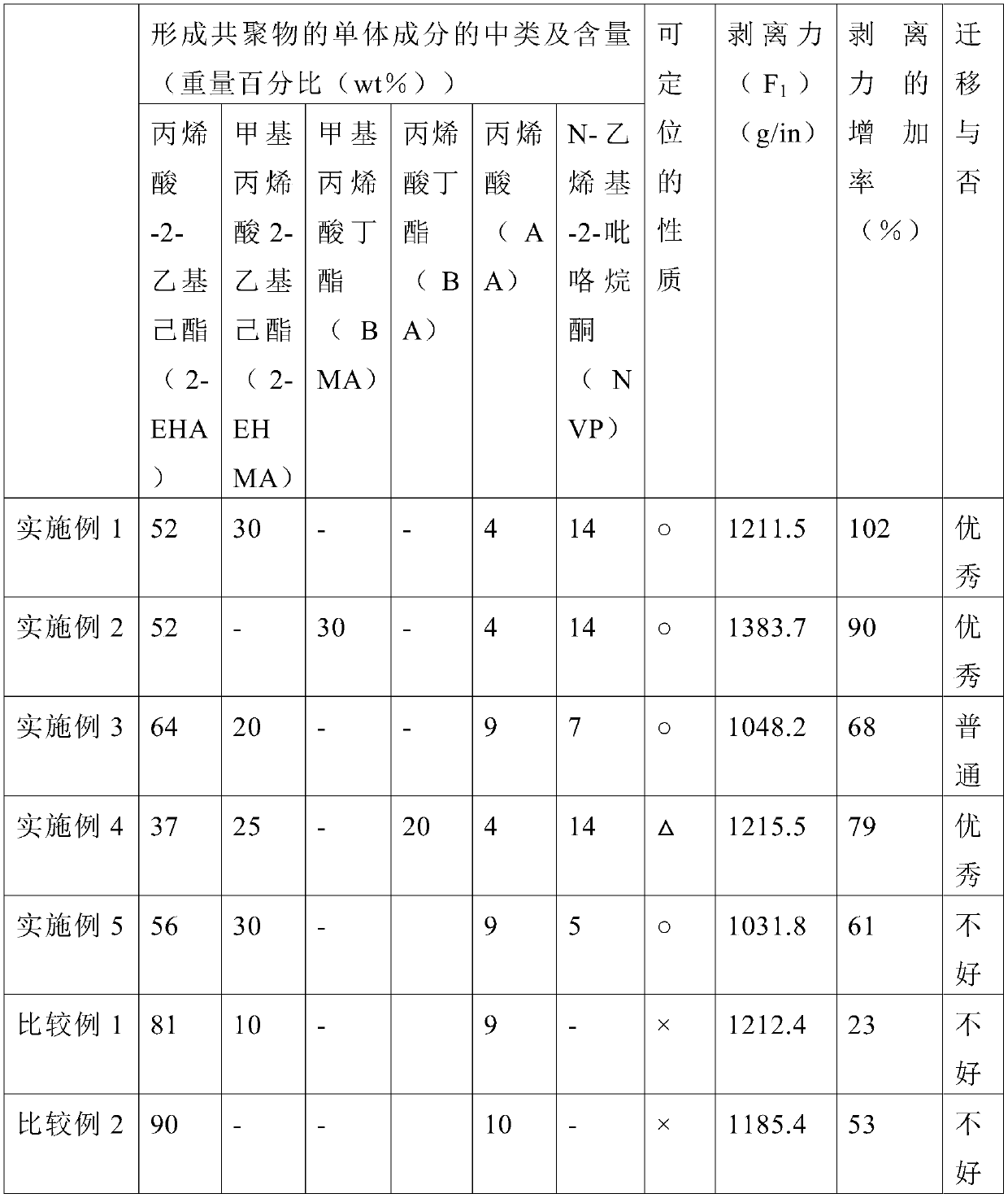

[0108] Containing 2-ethylhexyl acrylate (2-EHA, 2-Ethylhexyl acrylate), 2-ethylhexyl methacrylate (2-EHMA, 2-Ethylhexyl methacrylate), acrylic acid (AA, acrylic acid) by solution polymerization acid), N-vinyl-2-pyrrolidone, a thermal initiator and a solvent for the polymerization of the thermal polymerization composition to prepare 2-ethylhexyl acrylate, 2-ethylhexyl methacrylate, acrylic acid and a copolymer of monomer components of N-vinyl-2-pyrrolidone, specifically, in the monomer components forming the above-mentioned copolymer, the content of 2-ethylhexyl acrylate is 52% by weight, and the above-mentioned methacrylic acid 2 - The content of ethylhexyl ester is 30% by weight, the content of the above-mentioned acrylic acid is 4% by weight, and the content of the above-mentioned N-vinyl-2-pyrrolidone is 14% by weight.

[0109] An adhesive composition was prepared by mixing and stirring 100 parts by weight of the above copolymer, 0.22 parts by weight of a bifunctional aziri...

Embodiment 2

[0111] Thermal polymerization of a polymerization composition comprising 2-ethylhexyl acrylate, butyl methacrylate (BMA, Butylmetacrylate), acrylic acid, N-vinyl-2-pyrrolidone, a thermal initiator, and a solvent by solution polymerization The reaction has prepared the copolymer comprising the monomer components of 2-ethylhexyl acrylate, butyl methacrylate, acrylic acid, N-vinyl-2-pyrrolidone, specifically, among the monomer components forming the above-mentioned copolymer , the content of 2-ethylhexyl acrylate is 52% by weight, the content of the above-mentioned butyl methacrylate is 30% by weight, the content of the above-mentioned acrylic acid is 4% by weight, and the content of the above-mentioned N-vinyl-2-pyrrolidone is 14 weight percent, except that, the bonding composition was prepared with the same conditions and methods as in Example 1.

Embodiment 3

[0113] In the monomer components forming the copolymer, the content of 2-ethylhexyl acrylate is 64% by weight, the content of 2-ethylhexyl methacrylate is 20% by weight, and the content of acrylic acid is 9% by weight. , The above-mentioned copolymer was prepared so that the content of the above-mentioned N-vinyl-2-pyrrolidone was 7% by weight, and an adhesive composition was prepared under the same conditions and method as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com