Disc hydraulic anti-lock brake and brake system

An anti-lock and brake technology, applied in the direction of brakes, brake types, brake transmission devices, etc., can solve the problems of large occupied space, difficult implementation, poor heat dissipation effect, etc., and achieve easy implementation and anti-lock braking. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

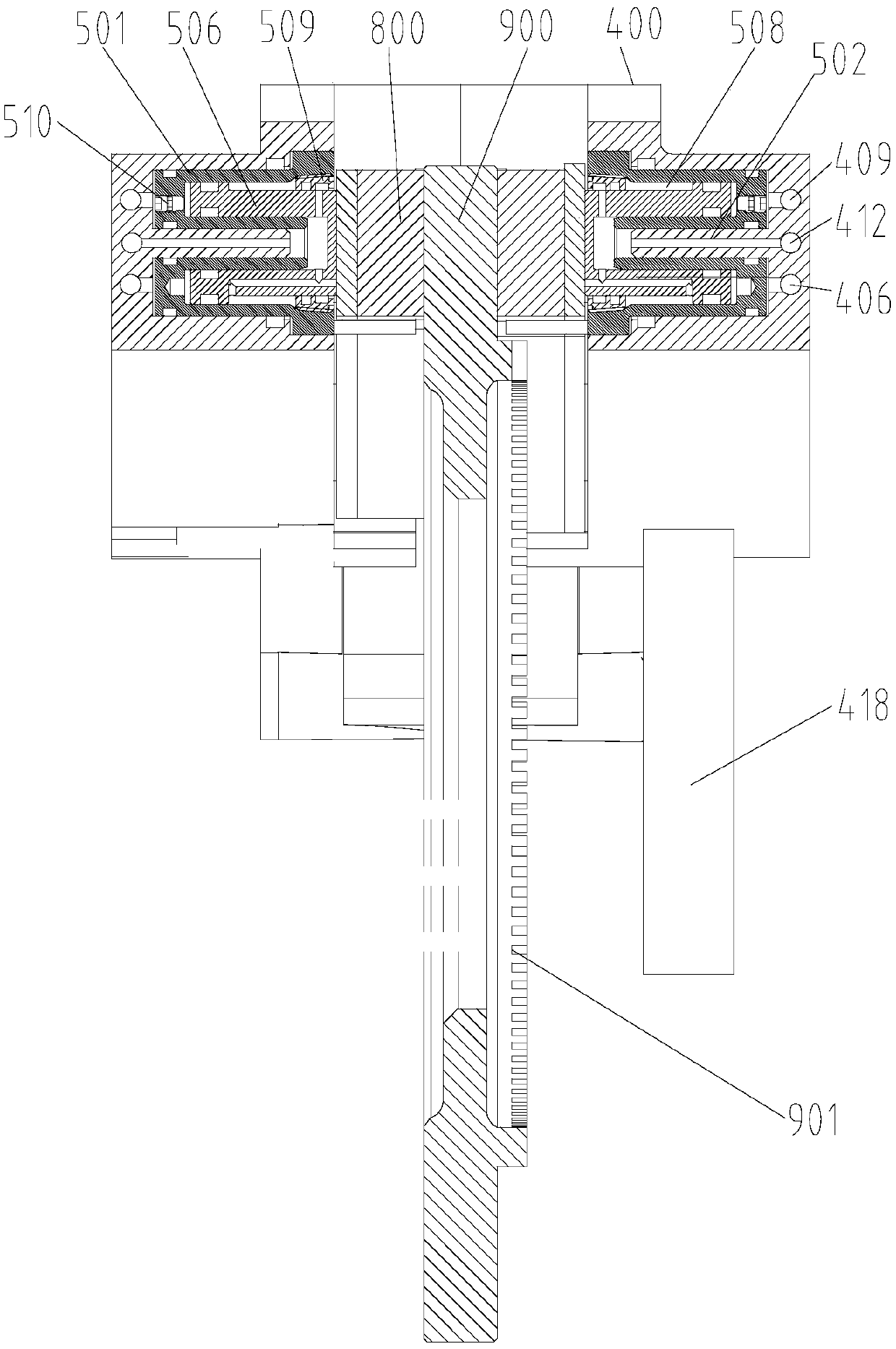

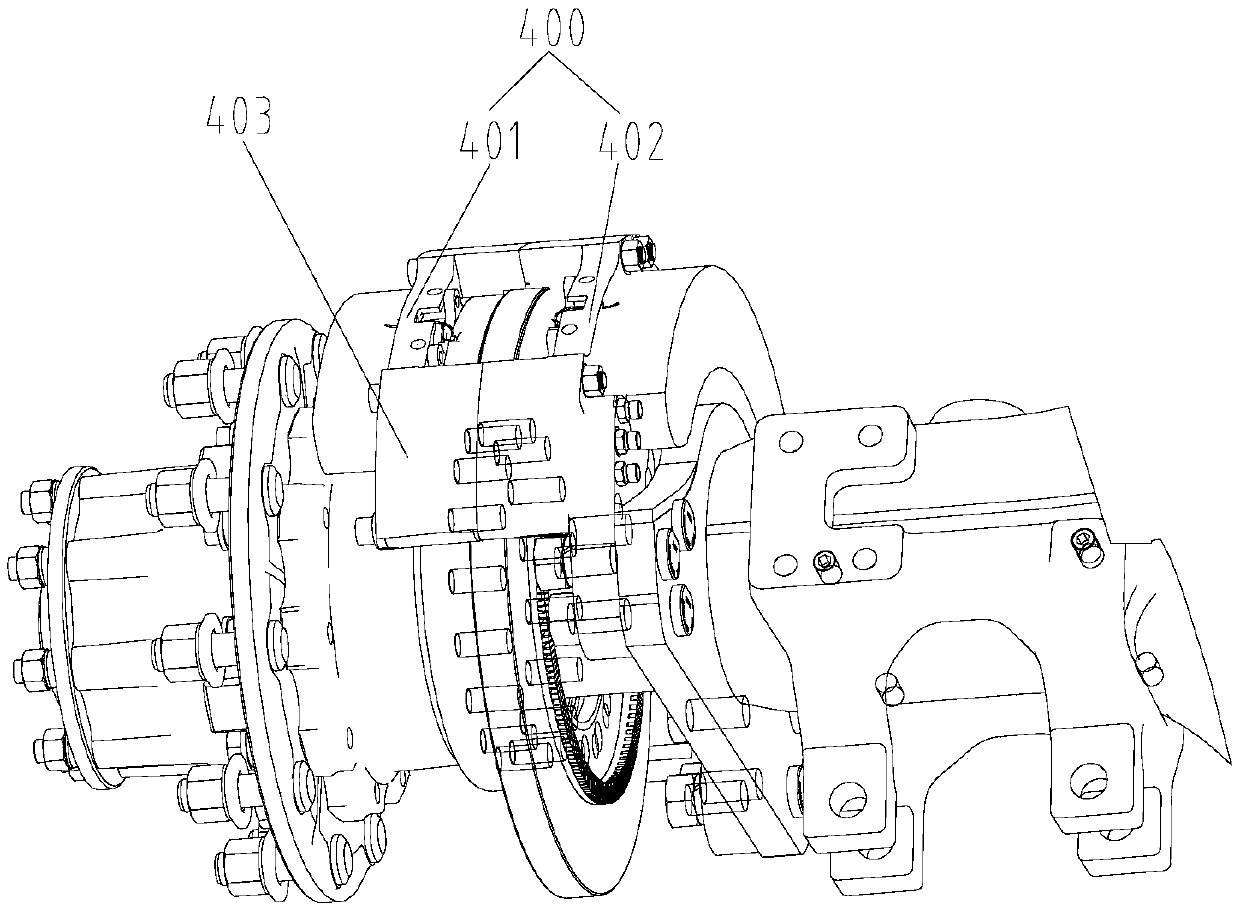

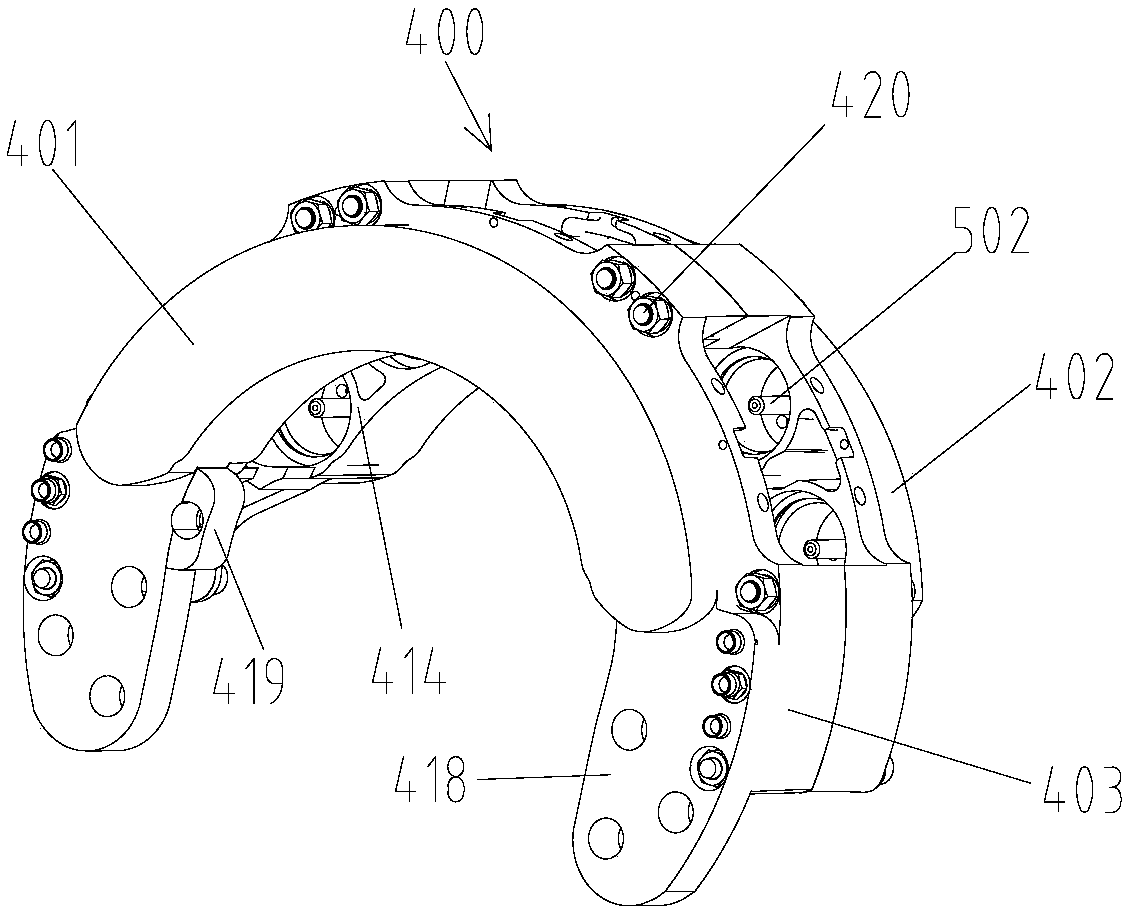

[0062] Such as Figure 1 to Figure 9 , Figure 13 to Figure 21 As shown, the present invention provides a disc hydraulic anti-lock brake, which includes a bracket 400, a first piston 501, a second piston 506, an elastic body 505, a brake pad 800, a brake disc 900, a release brake system and an anti-lock brake. dead brake system. Wherein, the first piston 501 is accommodated in the first cavity 415 of the bracket 400, and the first piston 501 can move axially in the first cavity 415, and the second piston 506 is accommodated in the second cavity 504 of the first piston 501, And the second piston 506 can move axially in the second cavity 504, and the end cap 509 covers the opening of the second cavity 504 and is fixedly connected with the second cavity 504 to limit the first piston 501 and the second piston 506. The limit motion stroke, the elastic body 505 is arranged between the second piston 506 and the bottom of the second cavity 504 to apply pressure to the first piston 5...

Embodiment approach 2

[0077] Such as Figure 10 to Figure 12 As shown, the present invention also provides a disc type hydraulic anti-lock brake, which differs from Embodiment 1 in that the first cavity 416 provided on the bracket 400 is used to accommodate the first piston 601 , and the second hole 416 provided on the bracket 400 The cavity 417 is used to accommodate the second piston 701 , the first cavity 416 and the second cavity 417 are arranged alternately, and according to these structural changes, the structures of the first piston 601 and the second piston 701 are adaptively changed.

[0078]Specifically, the disc hydraulic anti-lock brake includes: a bracket 400, which is provided with a first cavity 416, a second cavity 417, a core pipe 704, a channel, and brake pads arranged at the openings of the first cavity 416 and the second cavity 417. Seat and the mounting part for installing the bracket to the axle, the channel includes a first channel 406, a second channel 412 and a third channe...

Embodiment approach 3

[0082] Such as figure 1 , figure 2 with Figure 21 As shown, the present invention also provides a disc hydraulic anti-lock braking system, which is applied to the braking of motor vehicles, of course, it is not limited to automobiles, and it can also be applied to non-automotive braking, such as high-speed rail A braking system, the disc hydraulic anti-lock braking system includes a liquid container 103, a liquid pump, a liquid charging valve, an accumulator, a service brake valve, a parking brake valve, an axle 102, and a first pipeline 201 , the second pipeline 202, the third pipeline 203 and the disc hydraulic anti-lock brake; the disc hydraulic anti-lock brake is the disc hydraulic anti-lock brake described in Embodiment 1, its structure and working principle are the same and will not be repeated here;

[0083] When the liquid pump is working, the liquid in the liquid container 103 enters the accumulator under the action of the liquid pump and the filling valve and is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com