Cleaning and packaging treatment method of original accessories of excavator

A processing method and a technology for accessories, applied in cleaning methods and utensils, cleaning methods using liquids, packaging, etc., can solve the problems of incapable disc-shaped cutter wheel cutting, etc., to improve the rust prevention effect and reduce the frequency of frequent replacement. , to avoid the effect of cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

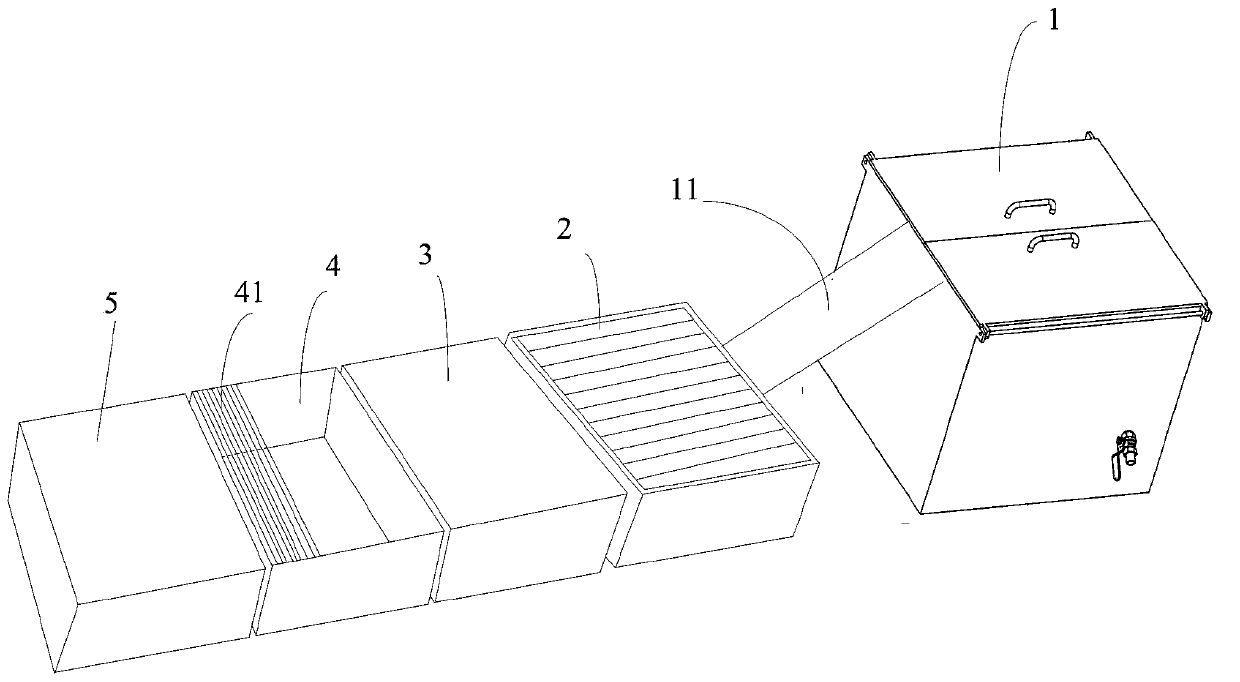

[0031] In order to realize the method for cleaning and packaging the original parts of excavators provided in the embodiment of the present invention, the embodiment of the present application provides a packaging processing system. For details, please refer to figure 1 Schematic diagram of the structure of the package handling system shown.

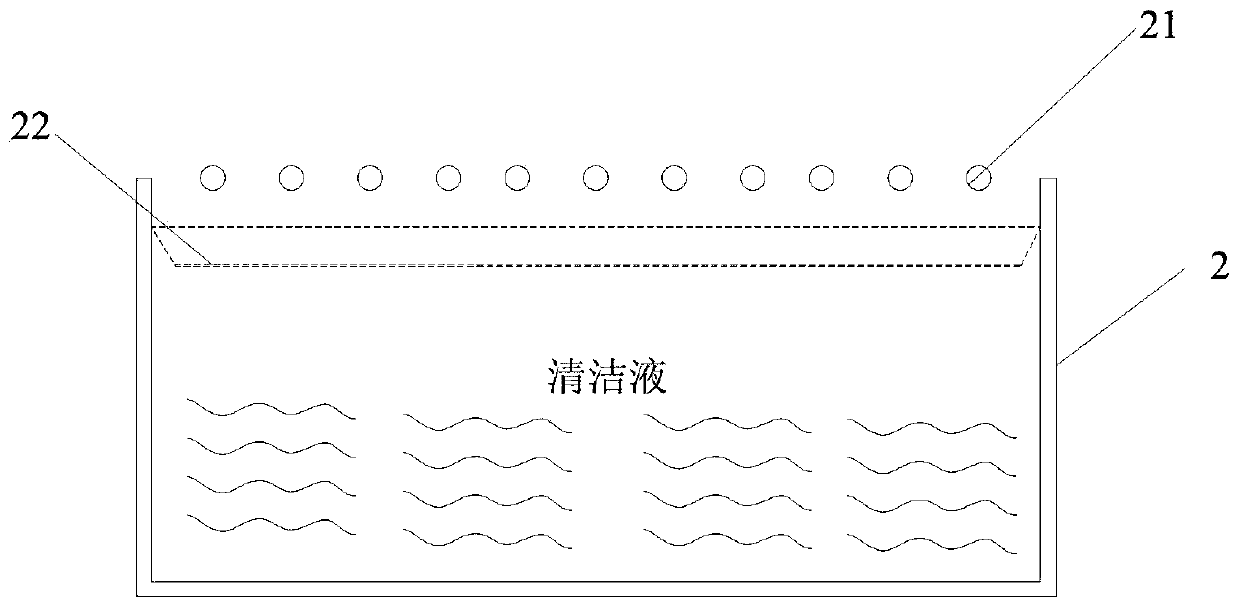

[0032] Such as figure 1 As shown, a packaging processing system provided by the embodiment of the present invention is used for cleaning and packaging the cylinder head. The packaging processing system includes an ultrasonic cleaning device 1, a water pool 2, a drying rack 3, a dipping pool 4, and a packaging table 5. The ultrasonic cleaning device 1, water pool 2, drying frame 3, dipping tank 4 and packaging table 5 are sequentially arranged to form an assembly line, and the ultrasonic cleaning, cleaning spray, drying, oil immersion, packaging and other steps are carried out sequentially to realize the cleaning Cleaning and packaging o...

Embodiment 2

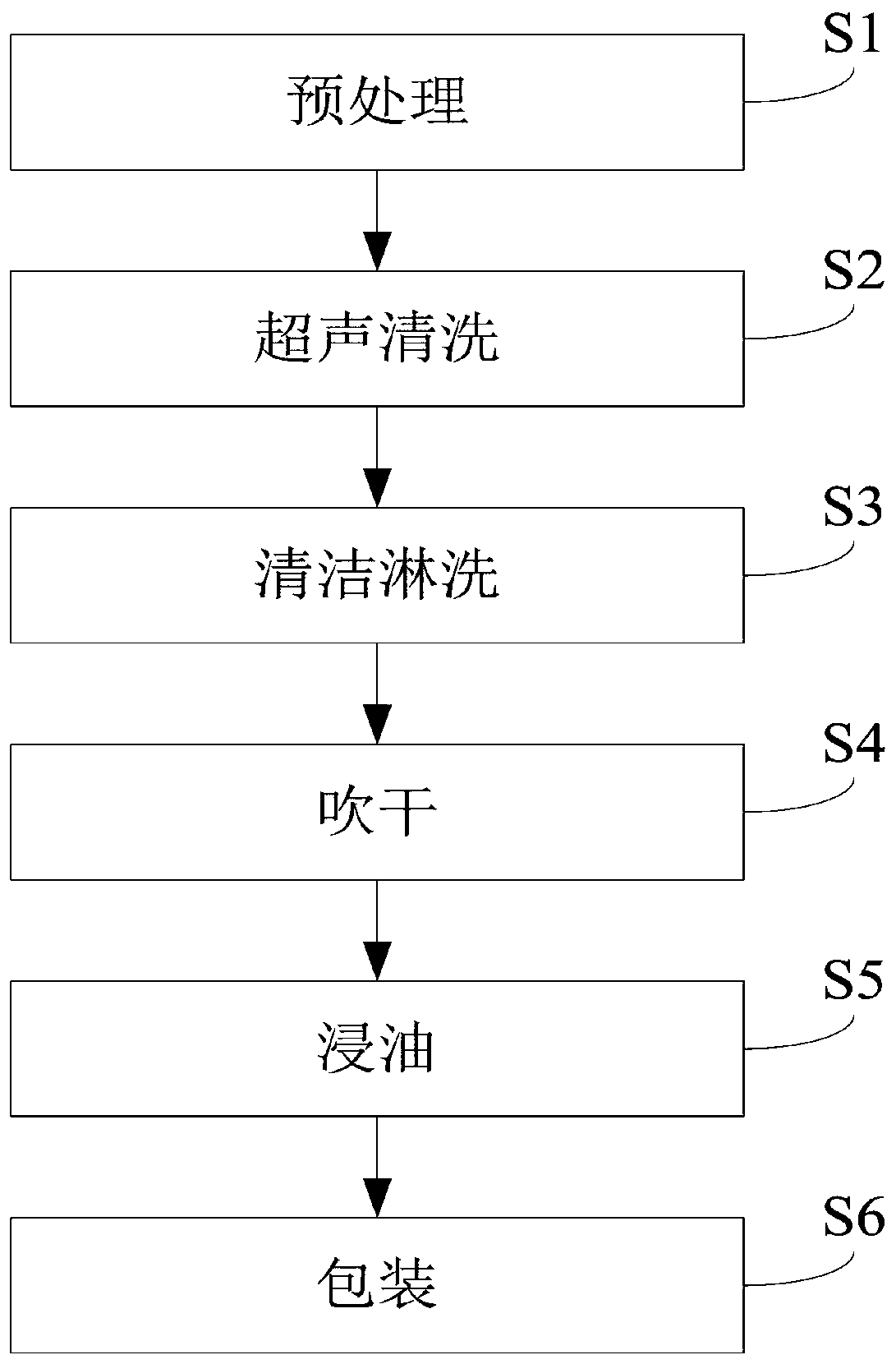

[0039] see image 3 As shown, combined with the above-mentioned embodiment 1, the embodiment of the present application provides a method for cleaning and packaging the original parts of the excavator. The method for cleaning and packaging includes:

[0040] Step S1: Preprocessing.

[0041] The outer surface of the cylinder head is treated with high-pressure air nozzles to remove dust and partially attached metal shavings.

[0042] Step S2: ultrasonic cleaning.

[0043] Open the cover of the ultrasonic cleaning device, place a number of cylinder heads evenly in the ultrasonic cleaning device filled with water, cover the cover, and control the ultrasonic cleaning device to perform ultrasonic cleaning for 1-3 minutes.

[0044] In the specific implementation process, the ultrasonic current of the ultrasonic instrument in the step S2 is 0.3A. At this time, the ultrasonic cleaning effect on the cylinder head is the best. The water temperature in the ultrasonic cleaning device is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com