Distributed control method, electronic equipment and storage medium for vulcanization process

A distributed control and process technology, applied in manufacturing computing systems, data processing applications, forecasting, etc., can solve the problems of unstable product performance, product over-vulcanization, time-consuming and labor-intensive, etc., to save resources, stabilize product performance, and control the process. Simple and effective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

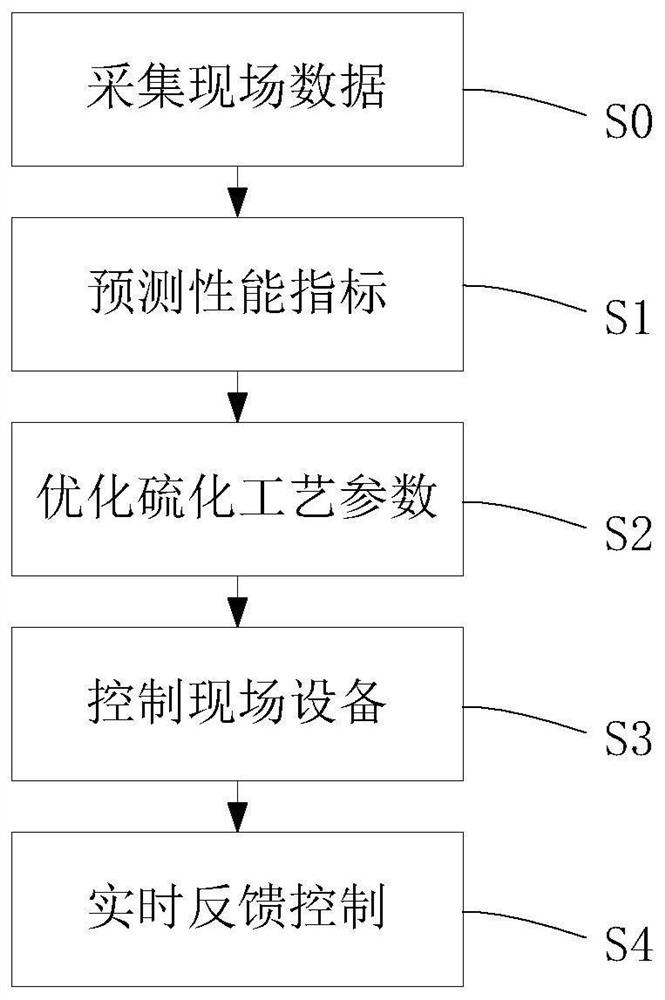

[0028] Distributed control method of vulcanization process, such as figure 1 shown, including the following steps:

[0029] S0. Collect on-site data. The central operation station communicates with several on-site control stations in real time. Each on-site control station controls several vulcanizing machines. The station receives the on-site control station to collect several groups of vulcanization process parameters and corresponding product performance indicators of several vulcanizers, divides several groups of vulcanization process parameters into input sample sets and verification sample sets, and takes the product performance indicators corre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com