Shower gel pouring system

A filling system and shower gel technology, applied in packaging, bottle filling, liquid bottling, etc., can solve the problems of high operator requirements, inability to meet production needs, low work efficiency, etc., reducing labor intensity, filling and filling. High efficiency and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

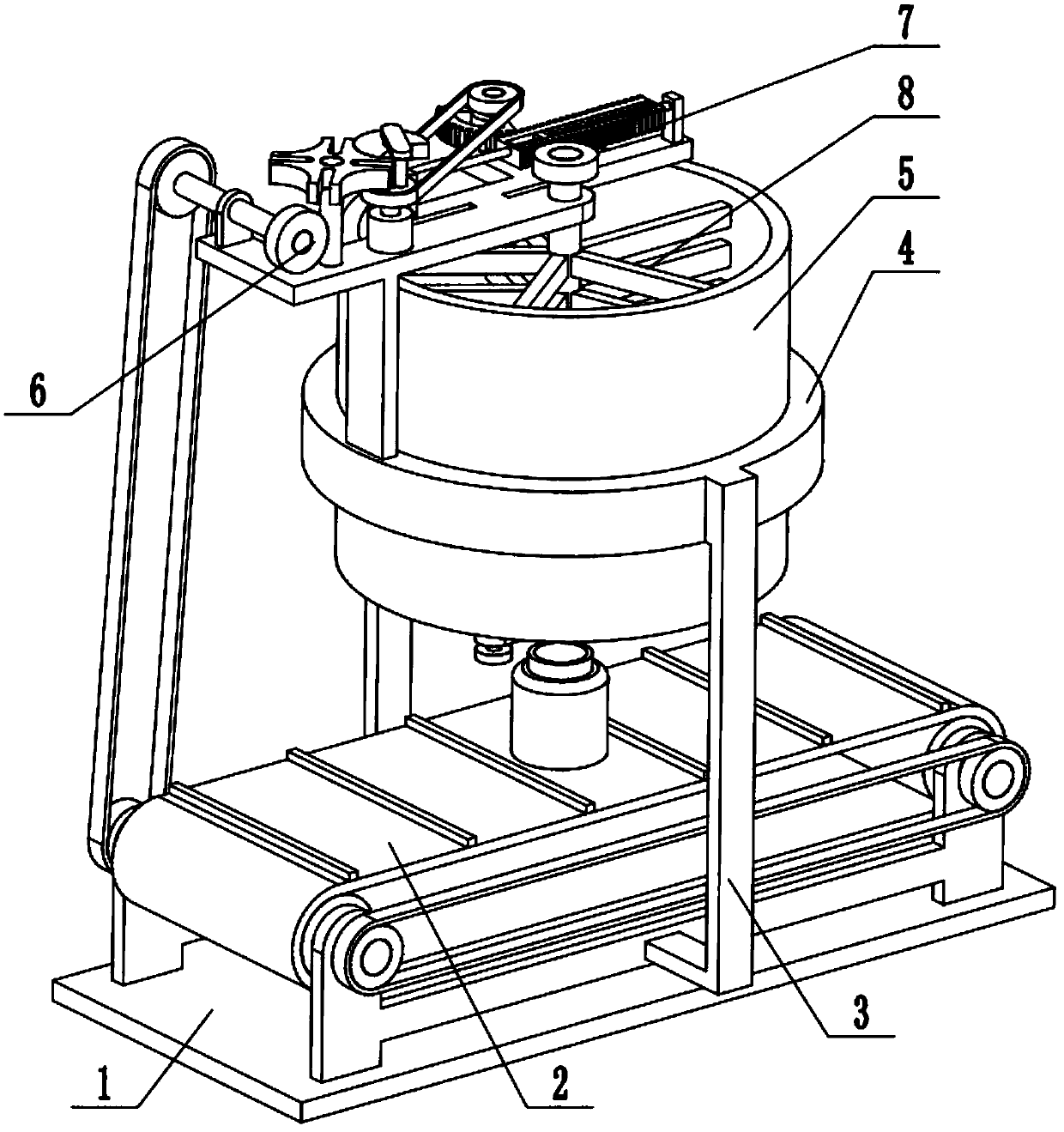

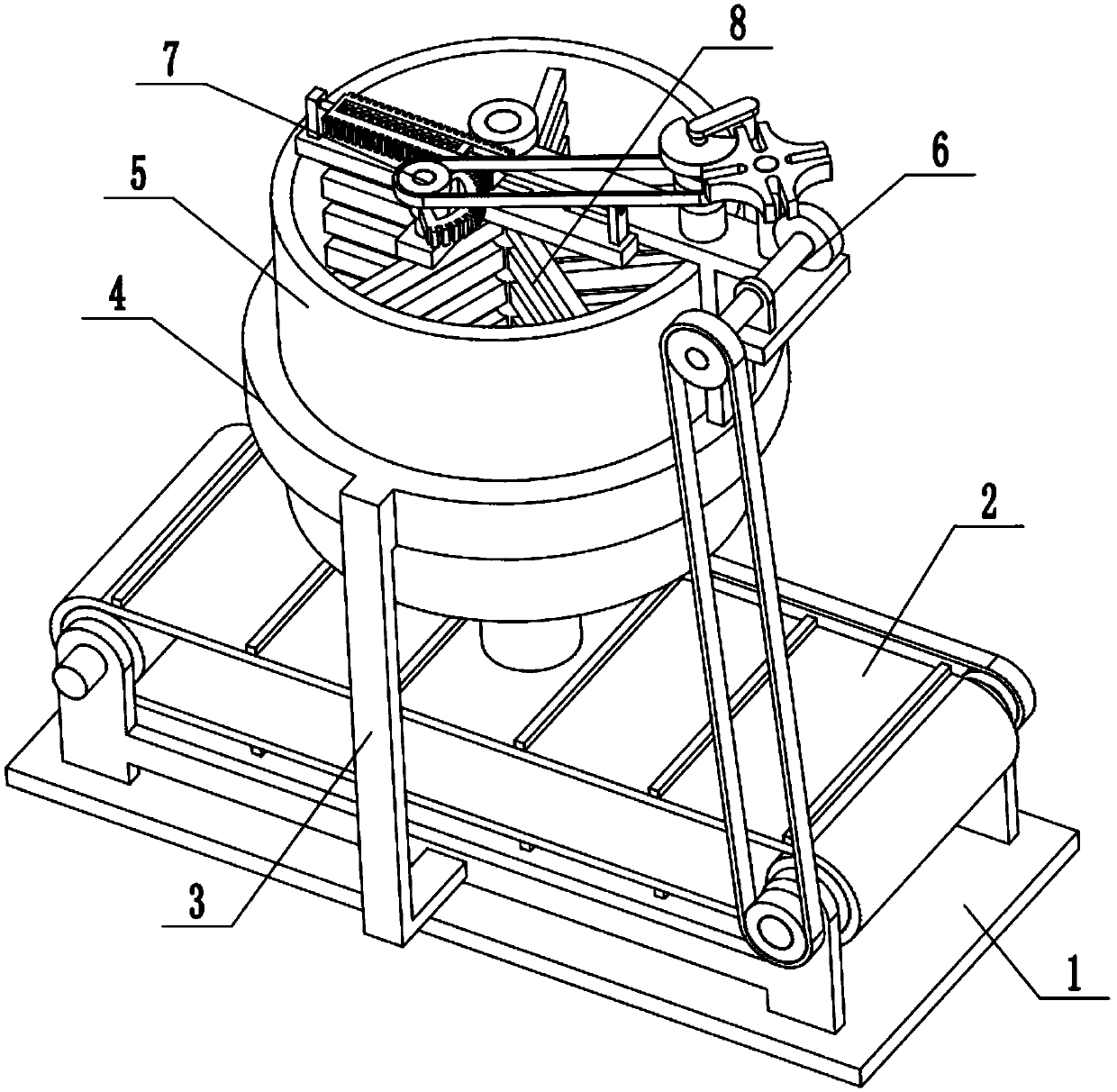

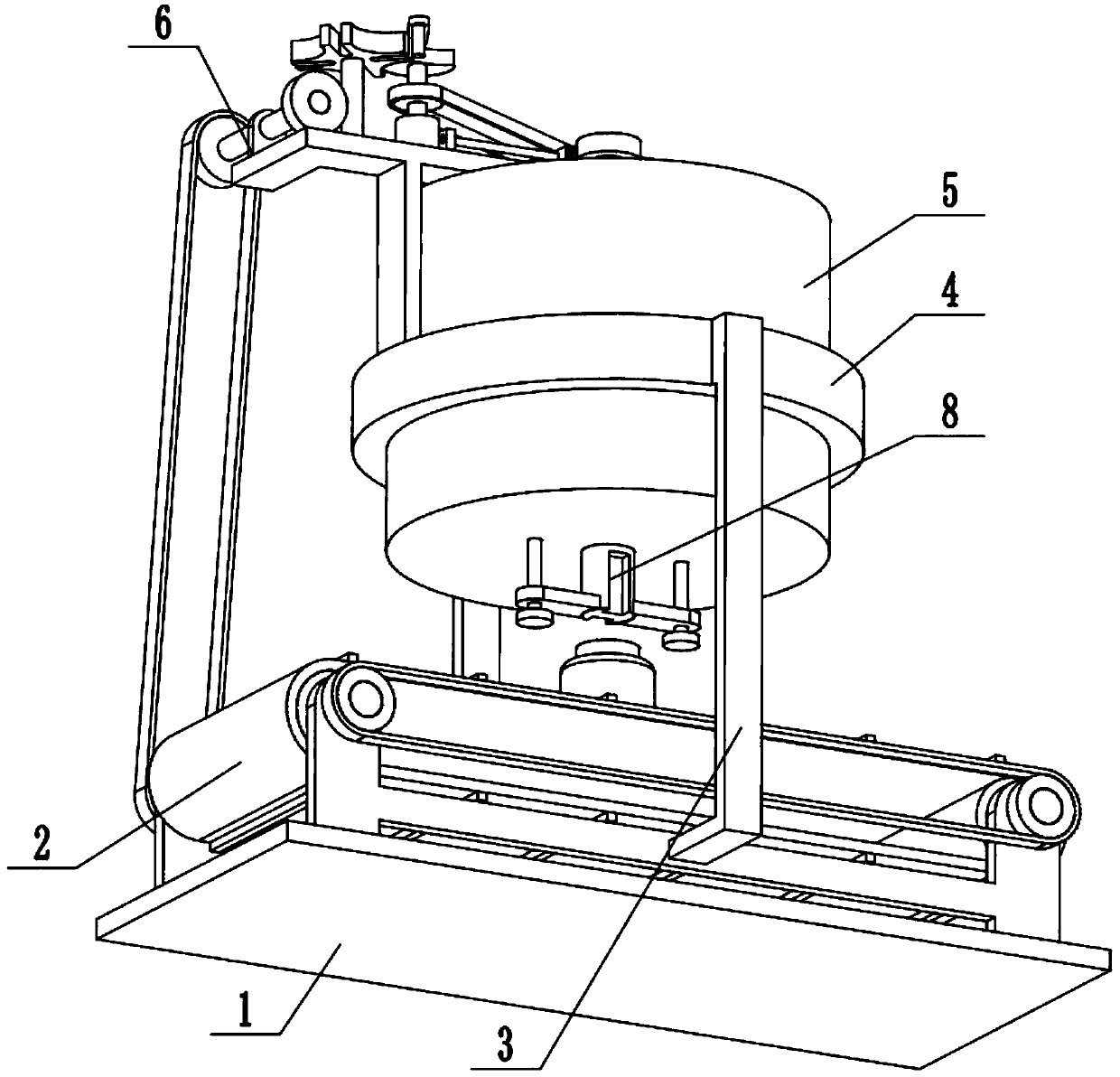

[0026] Combine below Figure 1-9Describe this embodiment, a shower gel filling system, including a bottom plate 1, a transmission assembly 2, a C-shaped connecting rod 3, a ring-shaped fixing seat 4, a shower gel storage box 5, a power transmission wheel assembly 6, and an intermittent discharge control mechanism 7 and an intermittent discharge mechanism 8, the transmission assembly 2 is fixedly connected to the bottom plate 1, two C-shaped connecting rods 3 are symmetrically fixedly connected to the front and rear ends of the transmission assembly 2, and the ring-shaped fixing seat 4 is fixedly connected to the two The upper end of the C-shaped connecting rod 3, the shower gel storage box 5 is fixedly connected to the inner side of the ring-shaped fixed seat 4, the power transmission wheel assembly 6 is fixedly connected to one end of the ring-shaped fixed seat 4, and the power transmission wheel assembly 6 and the transmission assembly 2 pass through Belt drive connection, t...

specific Embodiment approach 2

[0027] Combine below Figure 1-9 To illustrate this embodiment, the conveying assembly 2 includes a first roller shaft 2-1, a second roller shaft 2-2, a left leg 2-3, a right leg 2-4, a roller 2-5, Conveyor belt body 2-6, transverse baffle plate 2-7, connecting plate 2-8, linkage pulley Ⅰ 2-9, transmission pulley 2-10 and linkage pulley Ⅱ 2-11; two parts of the first roller shaft 2-1 The two ends of the second roller shaft 2-2 are respectively connected to the two right legs 2-4 through the bearings on the two right legs 2-4 through the bearings with seats. The left outrigger 2-3 and the two right outriggers 2-4 are all fixedly connected on the bottom plate 1; the middle ends of the first roller shaft 2-1 and the second roller shaft 2-2 are respectively fixedly connected with a roller The cylinder 2-5 and the two rollers 2-5 are connected through the transmission belt body 2-6, and the transmission belt body 2-6 is evenly provided with a plurality of transverse baffles 2-7; t...

specific Embodiment approach 3

[0028] Combine below Figure 1-9 To illustrate this embodiment, the power transmission wheel assembly 6 includes an L-shaped seat plate 6-1, a vertical plate 6-2, a motor 6-3, a driving shaft 6-4, a driving pulley 6-5, and an intermittent disc 6- 6. Intermittent wheel 6-7, worm screw 6-8, worm wheel 6-9, driving pulley 6-10, belt wheel rotating shaft 6-11 and shaft frame plate 6-12; L-shaped seat plate 6-1 passes through vertical plate 6 -2 is fixedly connected to the left end of the ring-shaped fixed seat 4, the motor 6-3 is fixedly connected to the L-shaped seat plate 6-1 through the motor frame, and the output shaft of the motor 6-3 is connected to the driving shaft 6-4 through a coupling, The intermittent disc 6-6 and the driving pulley 6-5 are fixedly connected to the driving shaft 6-4 sequentially from top to bottom, and the driving pulley 6-5 is connected with the intermittent discharge control mechanism 7 through a belt drive; the intermittent pulley 6 -6 is in cleara...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com