Refrigeration equipment and heat conduction part thereof

A technology of refrigeration equipment and heat conduction parts, applied in the field of preparation, can solve the problems of increasing the flow resistance of the refrigerant in the tube, hindering the full development of the refrigerant in the tube, and not being able to change the D-shaped tube evaporator, so as to improve refrigeration efficiency, reduce energy consumption, The effect of high cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the invention are described in detail below, examples of which are illustrated in the accompanying drawings. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

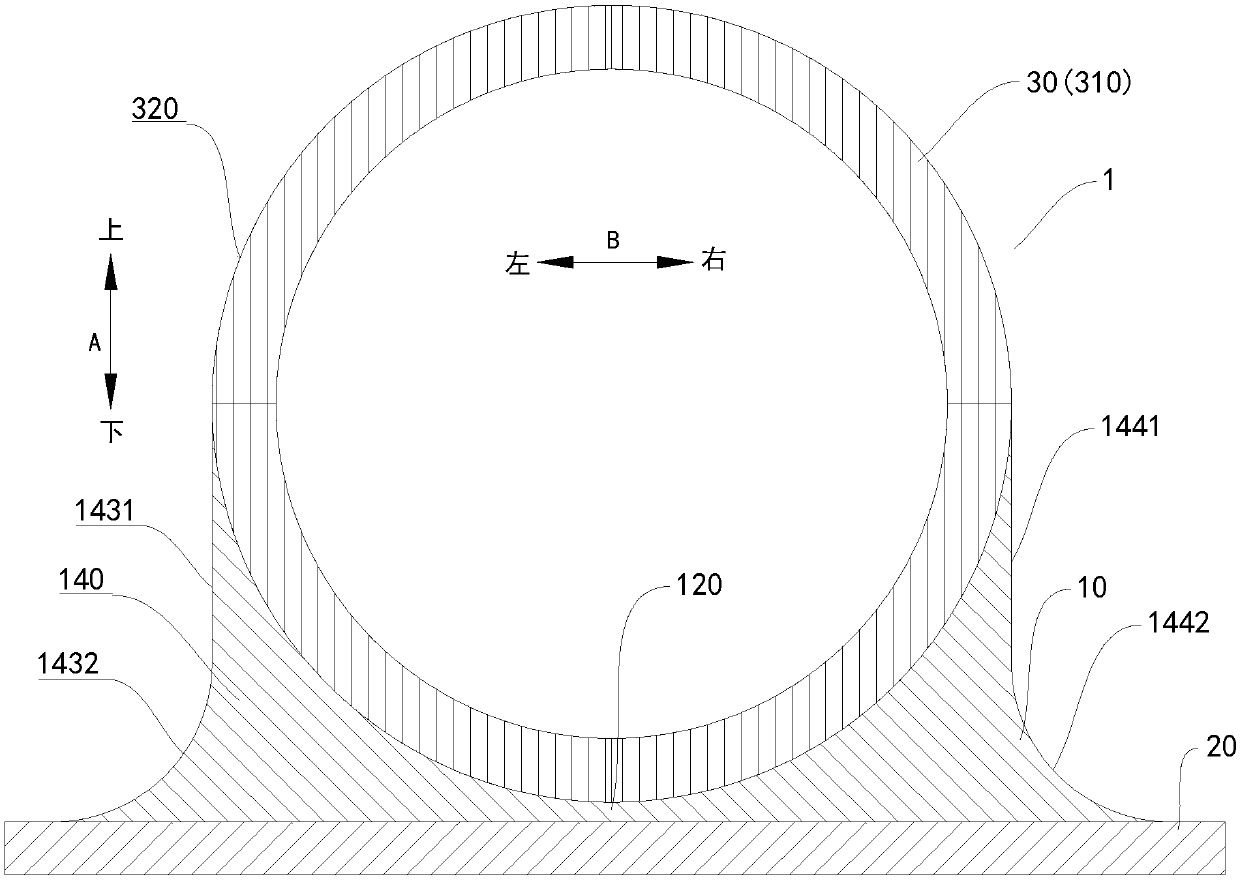

[0027] A refrigeration device 1 according to an embodiment of the present invention will be described below with reference to the drawings. like Figure 1-Figure 3 As shown, the refrigeration device 1 according to the embodiment of the present invention includes an inner container 20 , an evaporator 30 and a heat conducting element 10 .

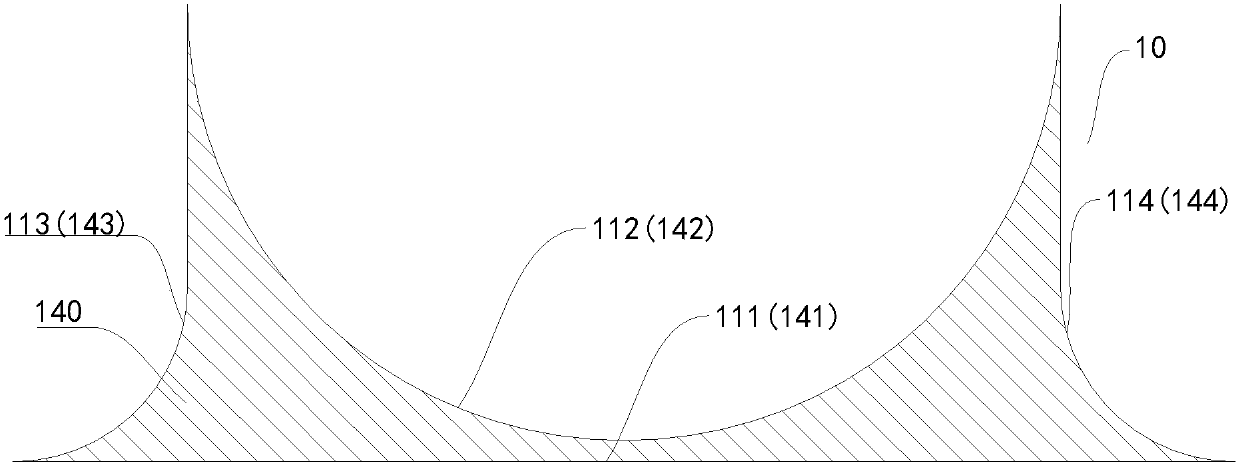

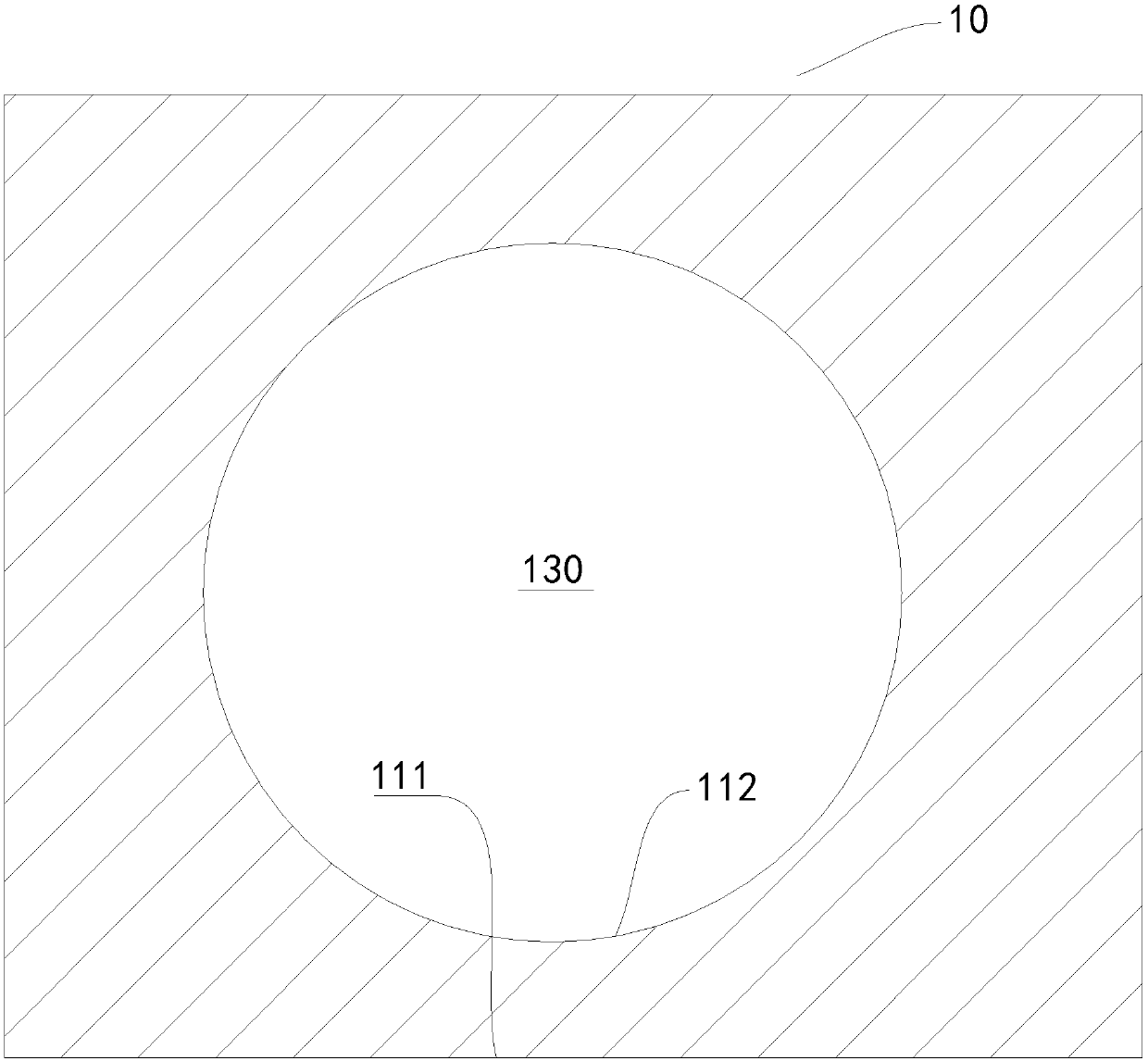

[0028] The evaporator 30 includes an evaporation tube 310 . The heat conducting element 10 has a first surface 111 and a second surface 112 opposite to each other, at least a part of the first surface 111 is a plane, and at least a part of the second surface 112 is a curved surface. Wherein, at least a part of the first surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Central angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com