Icing test system and method for wind turbine wing panel

A test system, wind turbine technology, applied in machine/structural component testing, aerodynamic tests, measuring devices, etc., can solve the lack of wind turbine icing physical experiment methods, can not be verified, and it is difficult to accurately obtain anti-icing heat load requirements etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

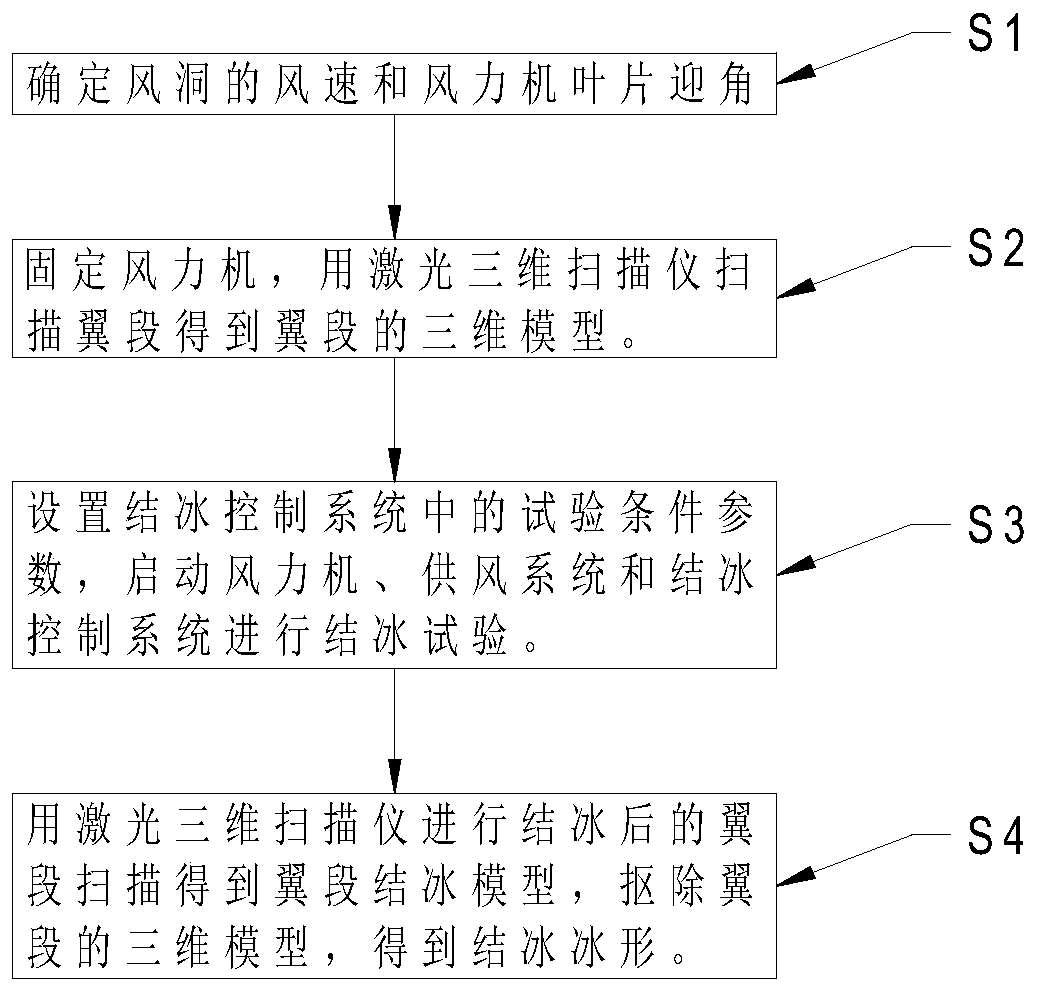

Method used

Image

Examples

Embodiment 1

[0025] A wind power wing segment icing test system, including a wind tunnel for dynamic tests, an air supply system that can adjust the wind speed of the wind tunnel test, and an icing control system for controlling the internal temperature and humidity of the wind; the icing The control system is connected with a refrigerating device and an atomizing spraying device, the refrigerating device is used for cooling the airflow of the air supply system, and the atomizing spraying device is used for mixing mist water droplets into the airflow of the air supply system; A support mechanism for fixing the wind turbine is arranged in the wind tunnel, and a laser three-dimensional scanner for scanning the blades of the wind turbine and generating a three-dimensional image is also arranged in the wind tunnel.

[0026] In this embodiment, the wind turbine is installed on the support mechanism so that the windward side of the blades of the wind turbine faces the direction of the incoming fl...

Embodiment 2

[0031] The maximum wind speed of the icing wind tunnel in this embodiment is 210m / s, the maximum Reynolds number is 1.4E+7; the range of liquid water content (LWC) is 0.2g / m 3 ~3g / m 3 , The mean droplet diameter (MVD) ranges from 10 μm to 300 μm.

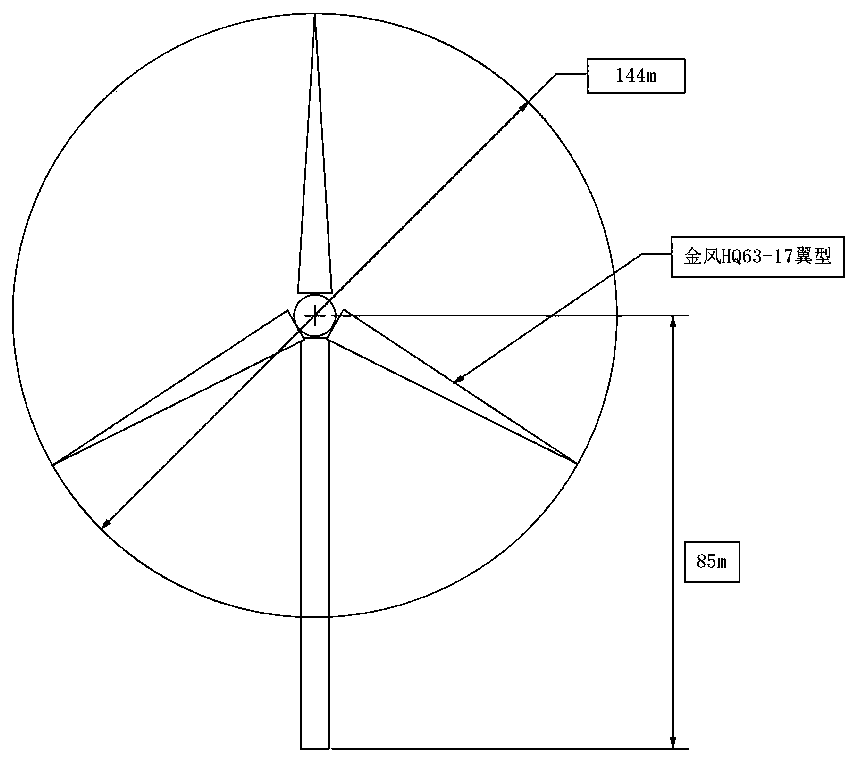

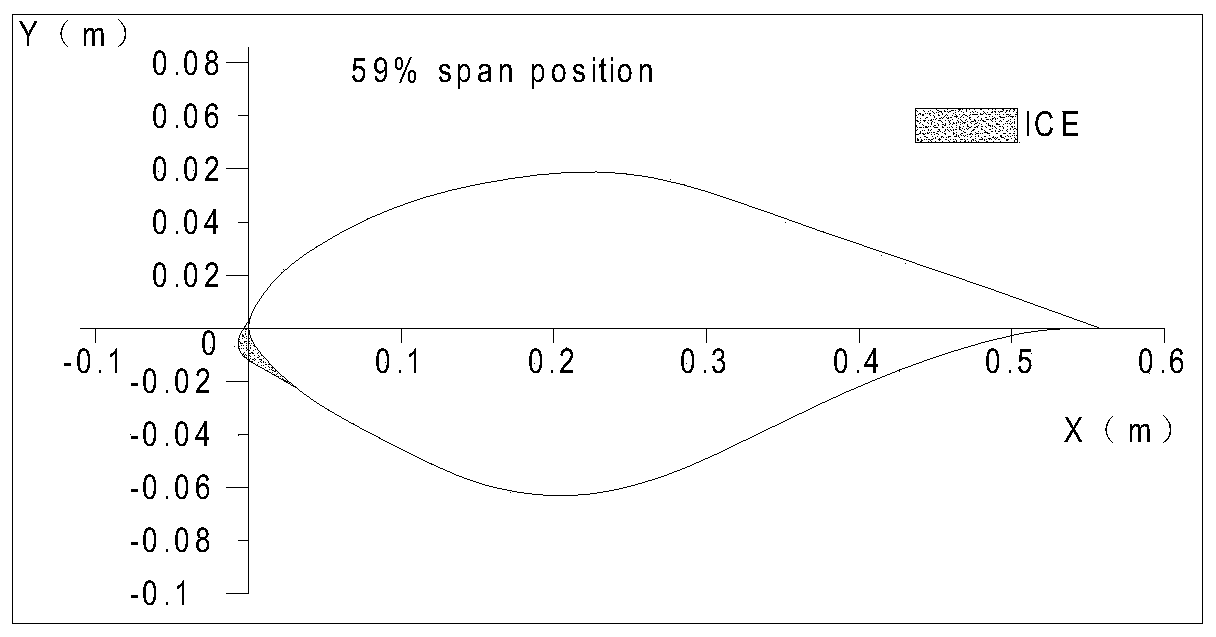

[0032] The airfoil of the wind turbine to be tested is the special airfoil of the Goldwind HQ63-17 wind turbine (such as figure 2 As shown), this airfoil is applied to a certain type of wind turbine. The diameter of the wind turbine rotor is 100m, and the height of the hub is 85m from the ground. In this example, the test wind speed is 23.2m / s, the angle of attack of the wind turbine is 5.26°, the controlled refrigeration temperature is -15°C, and the liquid water content is 0.9g / m 3 , the average droplet diameter is 20μm, and the freezing time is 600s;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com