Explosion test simulation experiment device for explosion-proof sealing wall

A technology for simulating experimental devices and airtight walls, applied to measuring devices, instruments, scientific instruments, etc., can solve the problems of gas explosion accidents caused by explosion-proof airtight walls, failure to truly reflect the mechanical properties and failure mechanisms of explosion-proof airtight walls, and meet the needs of the site desired effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

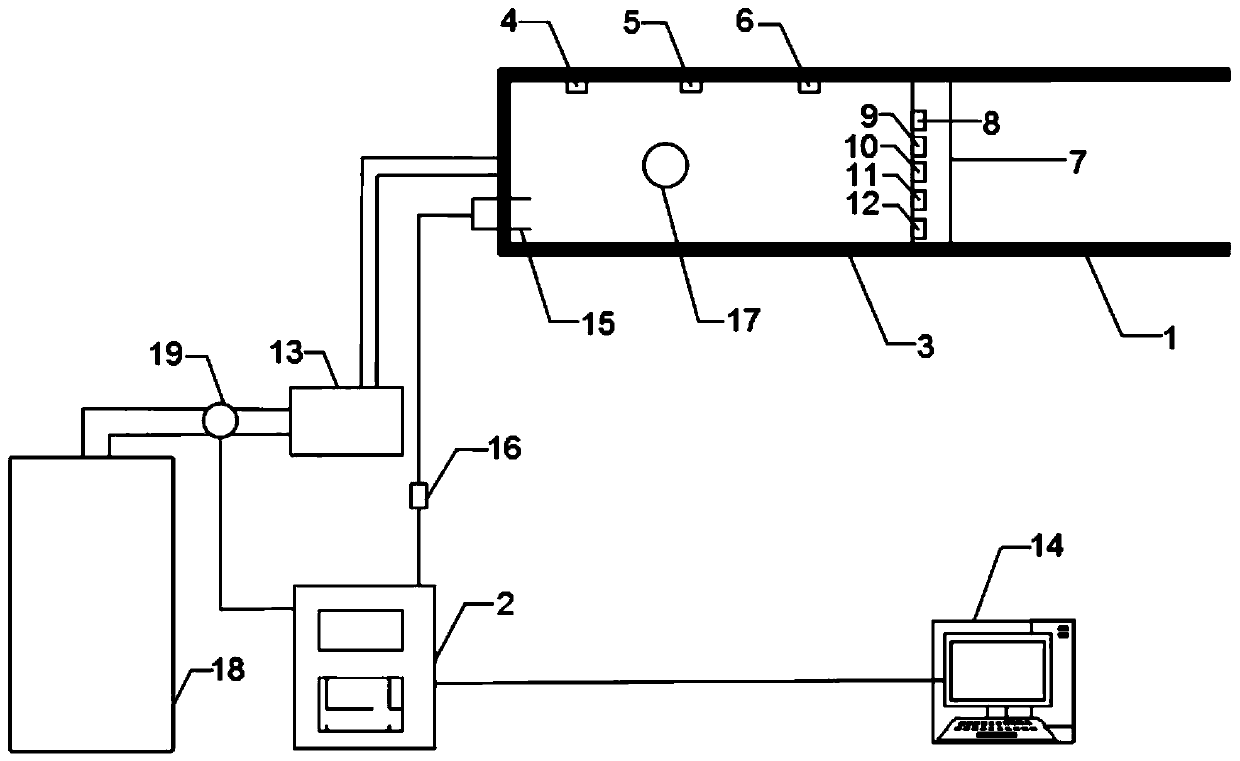

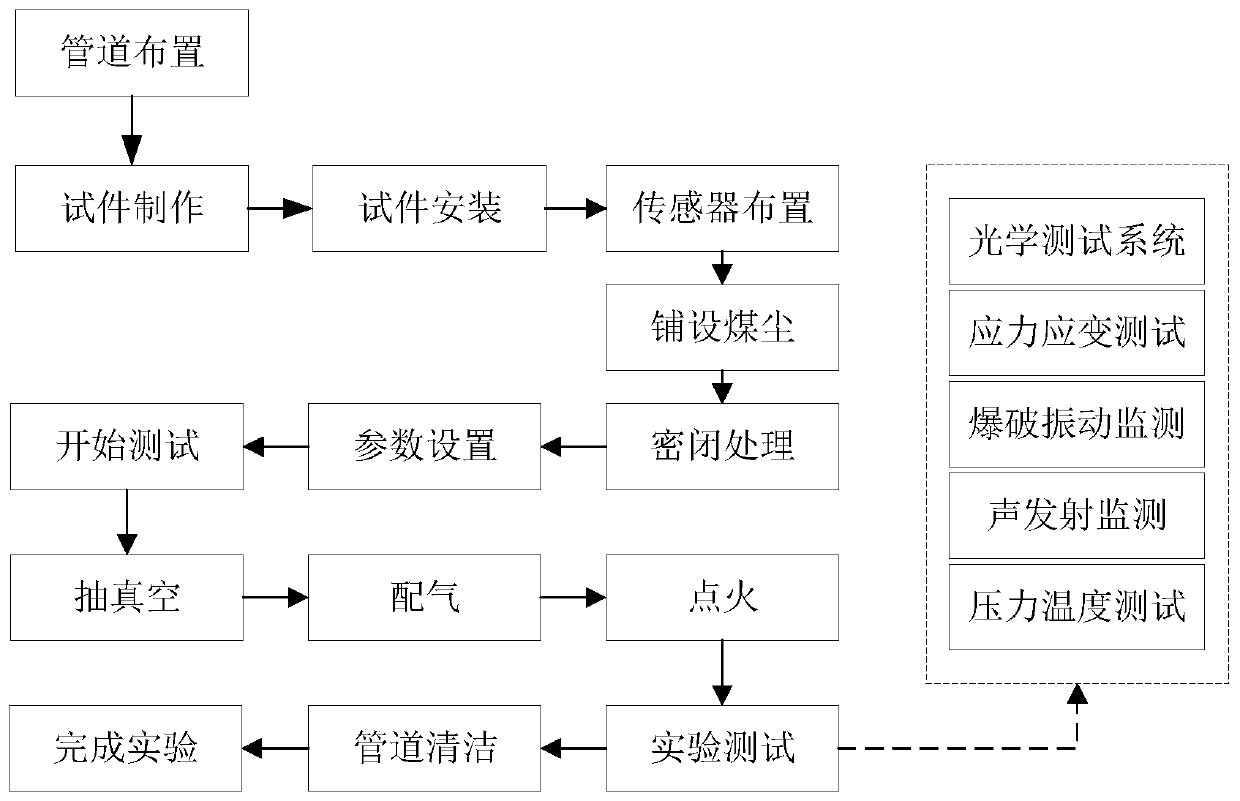

[0045] Specific implementation method: refer to figure 2 , an explosion test simulation experiment device for an explosion-proof airtight wall provided by the present invention, the most complicated situation is considered for the analysis of the experimental steps, and other situations are included in it according to the actual situation, that is, the two-phase explosion-suppressing material in the complex pipeline suppresses the complex group The failure mechanism and mechanical performance experiments of the explosion-proof airtight wall with multiple partial failures caused by the secondary explosion of coal dust caused by the sub-gas explosion.

[0046] Specifically include the following steps:

[0047] 1. According to the experimental requirements, set the pipeline layout and branch connection, and use flange connection between the pipelines.

[0048] 2. According to the requirements of the pipe section, the proportion of the pipe section is set by adjusting the rock t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com